Question: Upstate Mechanical, Inc., has been producing two bearings, components T79 and B81, for use in production. Data regarding these two components follow. * Variable manufacturing

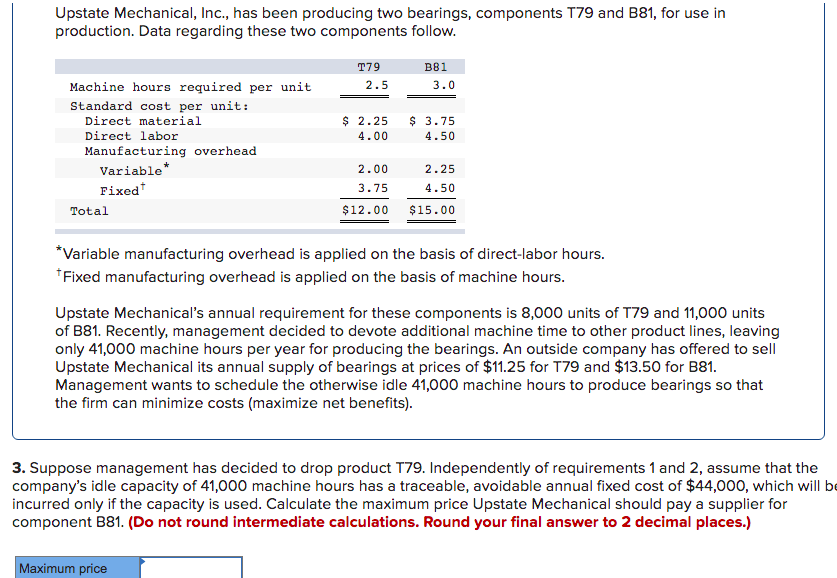

Upstate Mechanical, Inc., has been producing two bearings, components T79 and B81, for use in production. Data regarding these two components follow. * Variable manufacturing overhead is applied on the basis of direct-labor hours. Fixed manufacturing overhead is applied on the basis of machine hours. Upstate Mechanical's annual requirement for these components is 8,000 units of T79 and 11,000 units of B81. Recently, management decided to devote additional machine time to other product lines, leaving only 41,000 machine hours per year for producing the bearings. An outside company has offered to sell Upstate Mechanical its annual supply of bearings at prices of $11.25 for T79 and $13.50 for B81. Management wants to schedule the otherwise idle 41,000 machine hours to produce bearings so that the firm can minimize costs (maximize net benefits). 3. Suppose management has decided to drop product T79. Independently of requirements 1 and 2 , assume that the company's idle capacity of 41,000 machine hours has a traceable, avoidable annual fixed cost of $44,000, which will incurred only if the capacity is used. Calculate the maximum price Upstate Mechanical should pay a supplier for component B81. (Do not round intermediate calculations. Round your final answer to 2 decimal places.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts