Question: URGENT !!!!!!!!!! PLEASE ANSWER ASAPPPPP!!!!!!!!!!!!!!! (b) Monster Co requires a component that it installs in its core product. Starting next month, the company has idle

URGENT !!!!!!!!!! PLEASE ANSWER ASAPPPPP!!!!!!!!!!!!!!!

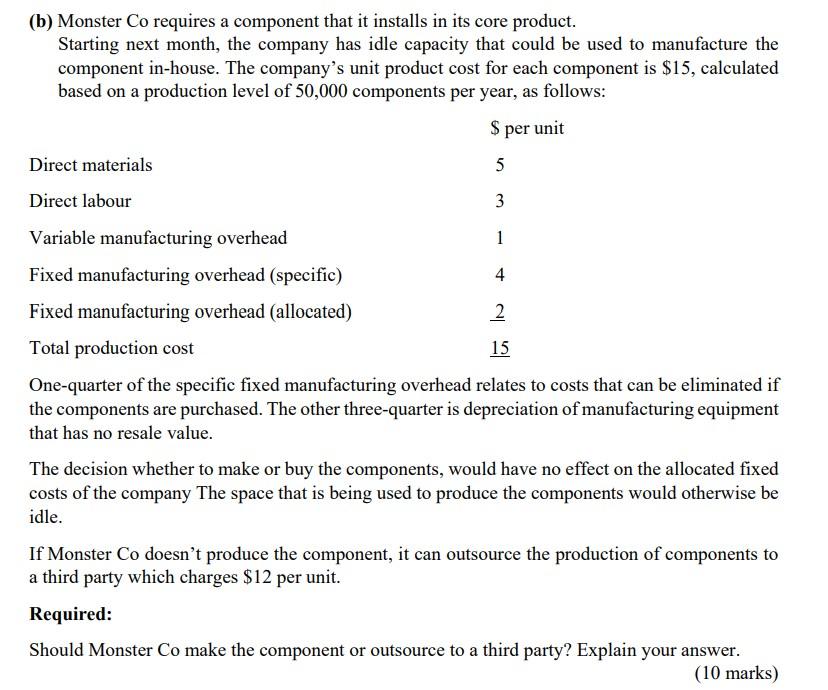

(b) Monster Co requires a component that it installs in its core product. Starting next month, the company has idle capacity that could be used to manufacture the component in-house. The company's unit product cost for each component is $15, calculated based on a production level of 50,000 components per year, as follows: $ per unit Direct materials 5 Direct labour 3 Variable manufacturing overhead 1 Fixed manufacturing overhead (specific) 4 Fixed manufacturing overhead (allocated) 2 Total production cost 15 One-quarter of the specific fixed manufacturing overhead relates to costs that can be eliminated if the components are purchased. The other three-quarter is depreciation of manufacturing equipment that has no resale value. The decision whether to make or buy the components, would have no effect on the allocated fixed costs of the company The space that is being used to produce the components would otherwise be idle. If Monster Co doesn't produce the component, it can outsource the production of components to a third party which charges $12 per unit. Required: Should Monster Co make the component or outsource to a third party? Explain your answer. (10 marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts