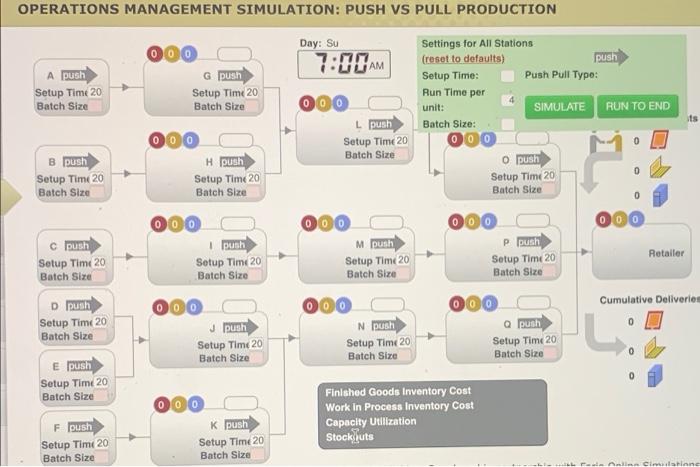

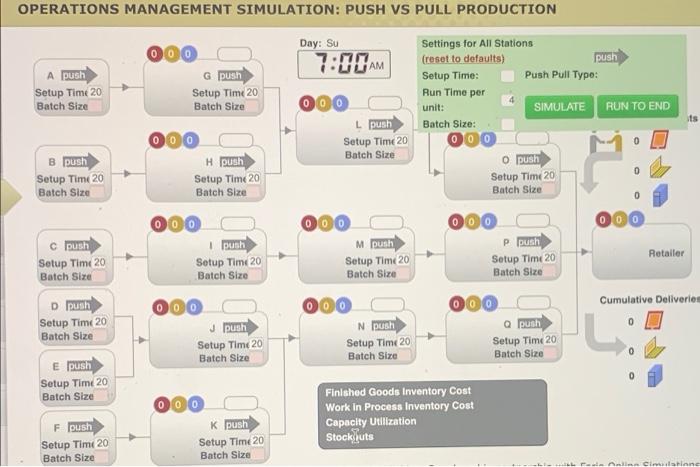

Question: Use default settings in scenario 3. What is the minimum batch size for all stations that results in the lowest total costs, while maintaining zero

Use default settings in scenario 3. What is the minimum batch size for all stations that results in the lowest total costs, while maintaining zero Stockouts?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock