Question: Use the KLF Electronics case below to complete Project charts for questions 1, 2, & 3. KLF Electronics KLF Electronics is an American manufacturer of

Use the KLF Electronics case below to complete Project charts for questions 1, 2, & 3.

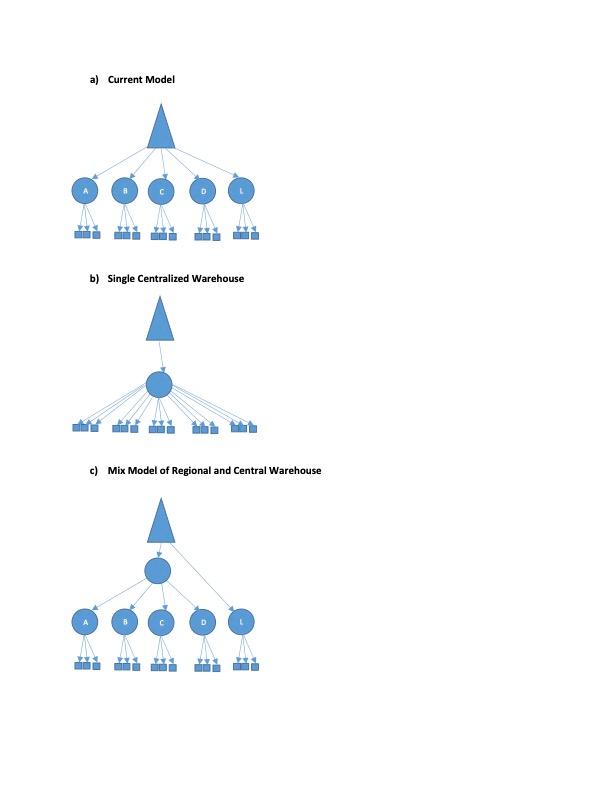

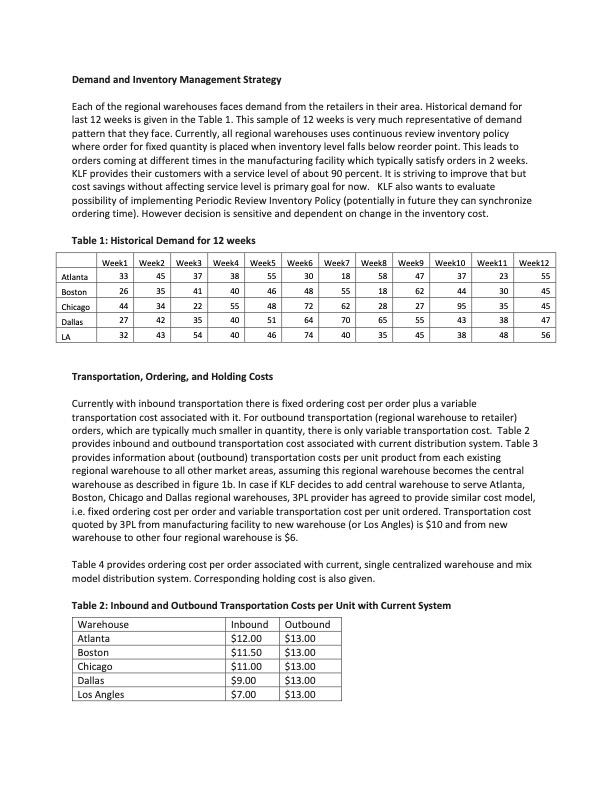

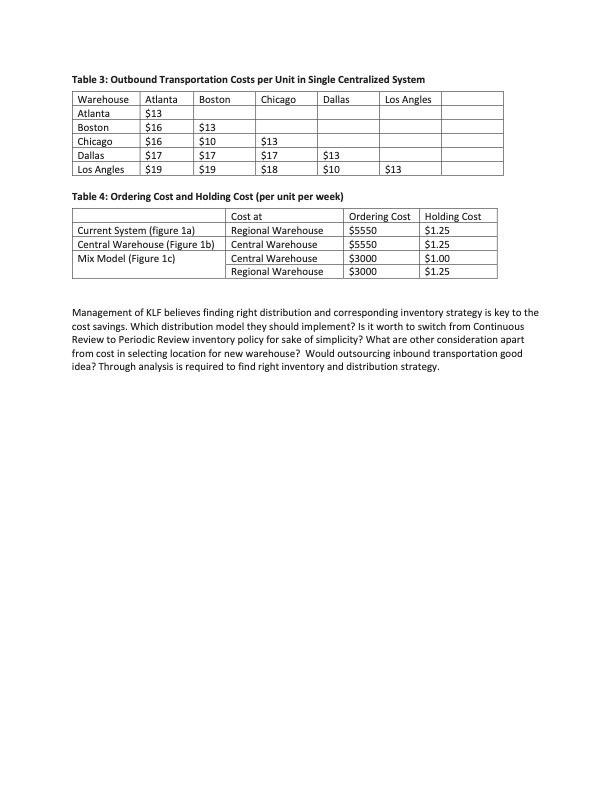

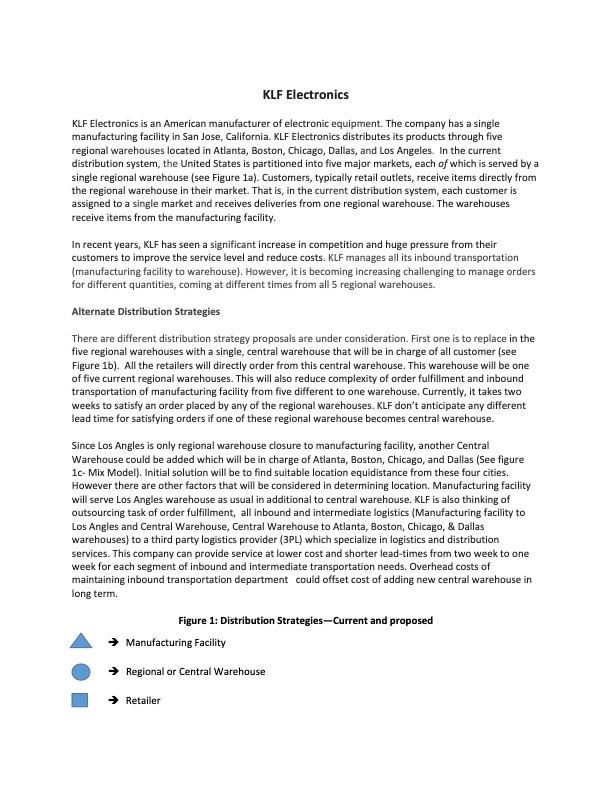

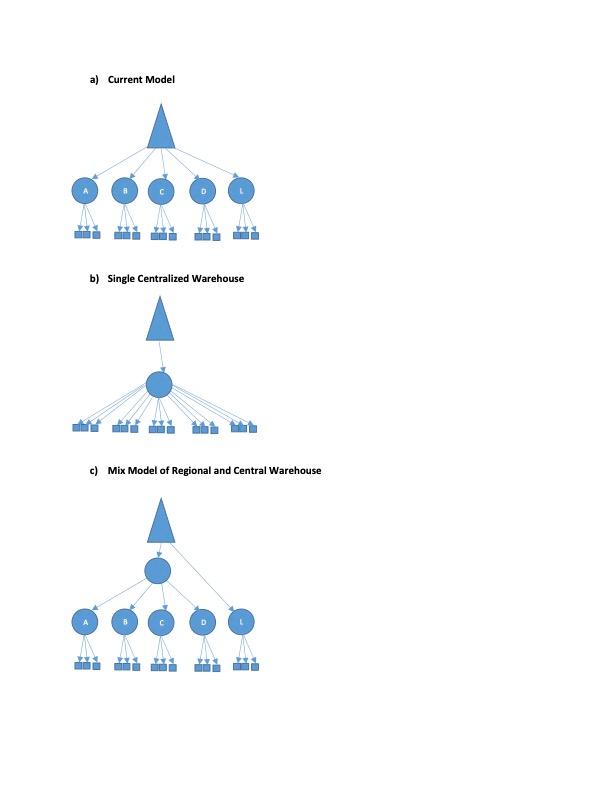

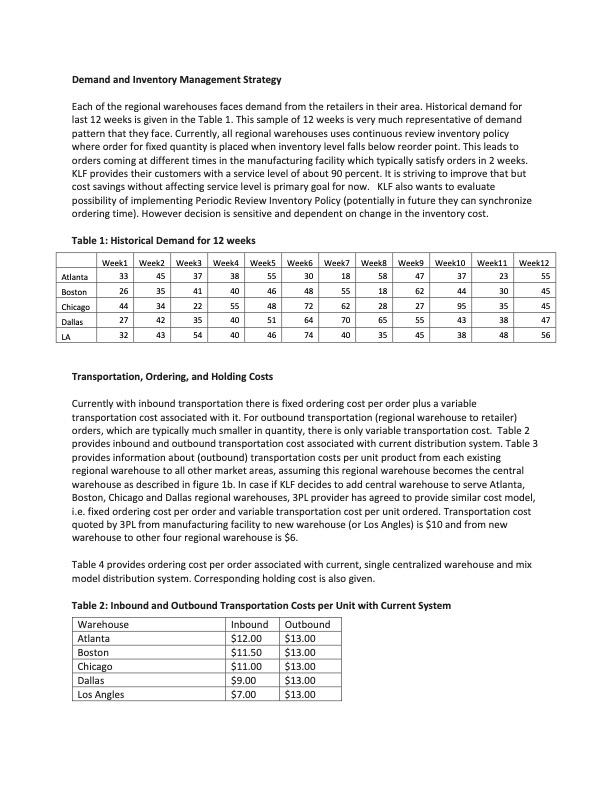

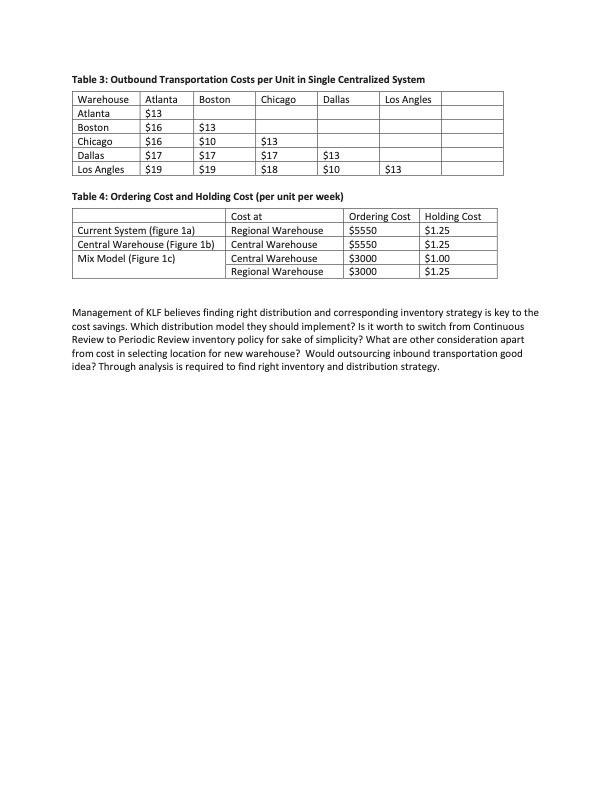

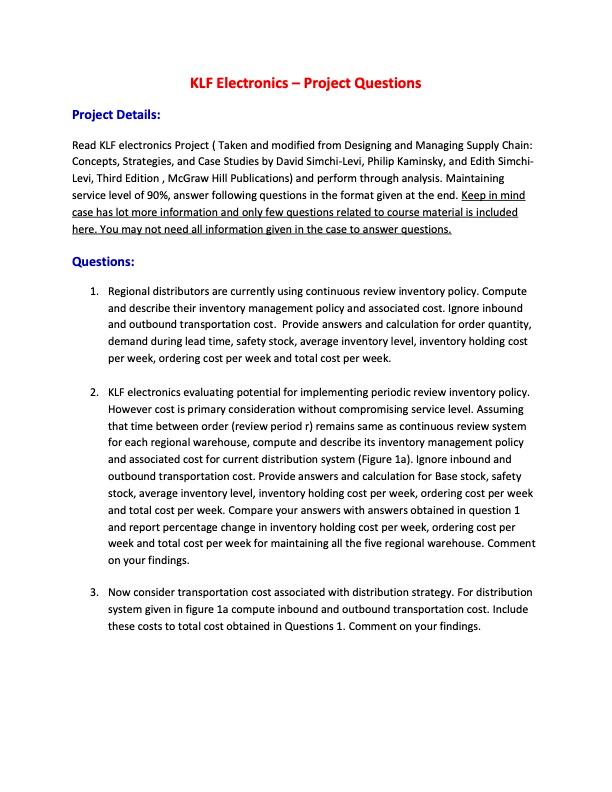

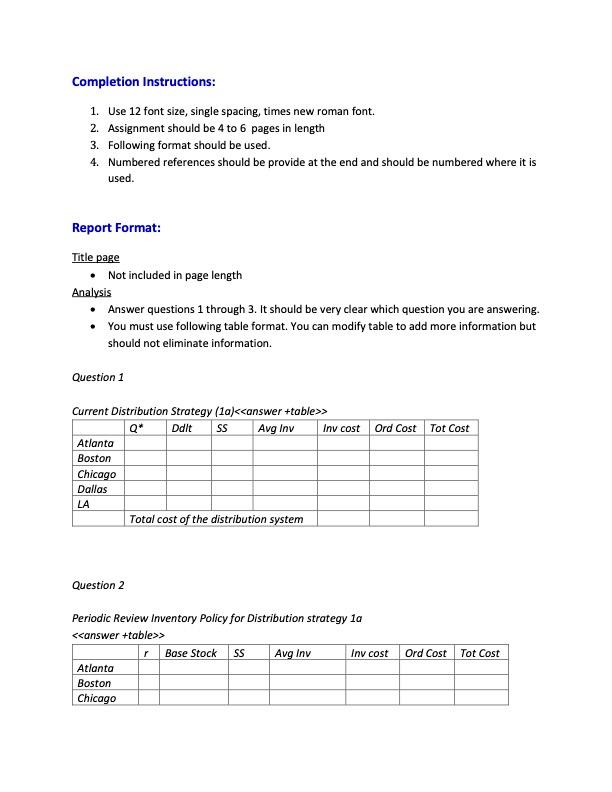

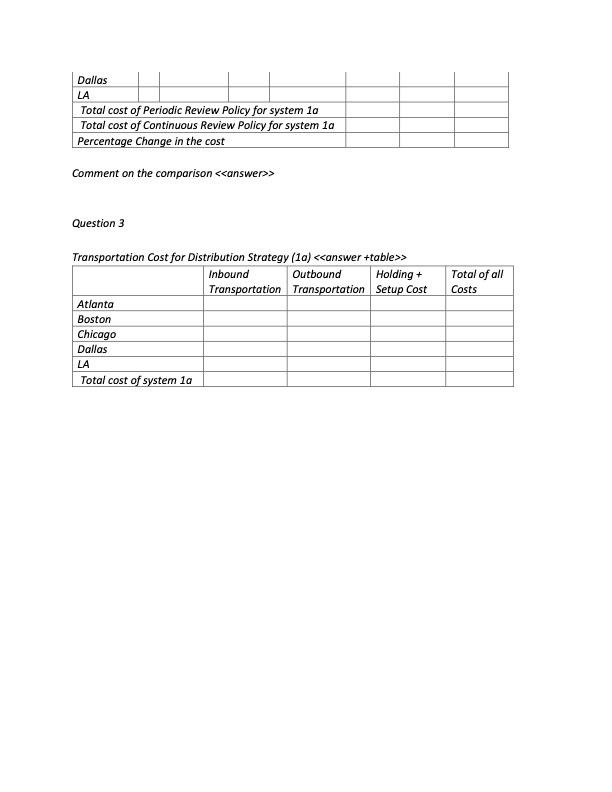

KLF Electronics KLF Electronics is an American manufacturer of electronic equipment. The company has a single manufacturing facility in San Jose, California. KLF Electronics distributes its products through five regional warehouses located in Atlanta, Boston, Chicago, Dallas, and Los Angeles. In the current distribution system, the United States is partitioned into five major markets, each of which is served by a single regional warehouse (see Figure 1a). Customers, typically retail outlets, receive items directly from the regional warehouse in their market. That is in the current distribution system, each customer is assigned to a single market and receives deliveries from one regional warehouse. The warehouses receive items from the manufacturing facility. In recent years, KLF has seen a significant increase in competition and huge pressure from their customers to improve the service level and reduce costs. KLF manages all its inbound transportation (manufacturing facility to warehouse). However, it is becoming increasing challenging to manage orders for different quantities, coming at different times from all 5 regional warehouses. Alternate Distribution Strategies There are different distribution strategy proposals are under consideration. First one is to replace in the five regional warehouses with a single, central warehouse that will be in charge of all customer (see Figure 1b). All the retailers will directly order from this central warehouse. This warehouse will be one of five current regional warehouses. This will also reduce complexity of order fulfillment and inbound transportation of manufacturing facility from five different to one warehouse. Currently, it takes two weeks to satisfy an order placed by any of the regional warehouses. KLF don't anticipate any different lead time for satisfying orders if one of these regional warehouse becomes central warehouse. Since Los Angles is only regional warehouse closure to manufacturing facility, another Central Warehouse could be added which will be in charge of Atlanta, Boston, Chicago, and Dallas (See figure 1c- Mix Model). Initial solution will be to find suitable location equidistance from these four cities. However there are other factors that will be considered in determining location. Manufacturing facility will serve Los Angles warehouse as usual in additional to central warehouse. KLF is also thinking of outsourcing task of order fulfillment, all inbound and intermediate logistics (Manufacturing facility to Los Angles and Central Warehouse, Central Warehouse to Atlanta, Boston, Chicago, & Dallas warehouses) to a third party logistics provider (3PL) which specialize in logistics and distribution services. This company can provide service at lower cost and shorter lead-times from two week to one week for each segment of inbound and intermediate transportation needs. Overhead costs of maintaining inbound transportation department could offset cost of adding new central warehouse in long term. Figure 1: Distribution Strategies --Current and proposed Manufacturing Facility Regional or Central Warehouse Retailer a) Current Model b) Single Centralized Warehouse c) Mix Model of Regional and Central Warehouse Demand and Inventory Management Strategy Each of the regional warehouses faces demand from the retailers in their area. Historical demand for last 12 weeks is given in the Table 1. This sample of 12 weeks is very much representative of demand pattern that they face. Currently, all regional warehouses uses continuous review inventory policy where order for fixed quantity is placed when inventory level falls below reorder point. This leads to orders coming at different times in the manufacturing facility which typically satisfy orders in 2 weeks. KLF provides their customers with a service level of about 90 percent. It is striving to improve that but cost savings without affecting service level is primary goal for now. KLF also wants to evaluate possibility of implementing Periodic Review Inventory Policy (potentially in future they can synchronize ordering time). However decision is sensitive and dependent on change in the inventory cost. Table 1: Historical Demand for 12 weeks Week11 Week 1 33 26 Week 2 45 35 Week 3 37 Week 4 38 Weeks 55 Week 6 30 Week9 47 Week 10 37 Week 12 55 41 40 48 62 44 45 Atlanta Boston Chicago Dallas LA 46 48 34 Week7 Week 18 58 55 18 62 28 70 65 40 35 72 27 95 44 27 22 35 883 U 60 8868 45 55 40 40 % 30 35 38 42 51 64 55 43 47 32 43 54 46 74 45 38 48 56 * Transportation, Ordering, and Holding Costs Currently with inbound transportation there is fixed ordering cost per order plus a variable transportation cost associated with it. For outbound transportation (regional warehouse to retailer) orders, which are typically much smaller in quantity, there is only variable transportation cost. Table 2 provides inbound and outbound transportation cost associated with current distribution system. Table 3 provides information about (outbound) transportation costs per unit product from each existing regional warehouse to all other market areas, assuming this regional warehouse becomes the central warehouse as described in figure 1b. In case if KLF decides to add central warehouse to serve Atlanta, Boston, Chicago and Dallas regional warehouses, 3PL provider has agreed to provide similar cost model, i.e. fixed ordering cost per order and variable transportation cost per unit ordered. Transportation cost quoted by 3PL from manufacturing facility to new warehouse (or Los Angles) is $10 and from new warehouse to other four regional warehouse is $6. Table 4 provides ordering cost per order associated with current, single centralized warehouse and mix model distribution system. Corresponding holding cost is also given. Table 2: Inbound and Outbound Transportation Costs per Unit with Current System Warehouse Inbound Outbound Atlanta $12.00 $13.00 Boston $11.50 $13.00 Chicago $11.00 $13.00 Dallas $9.00 $13.00 Los Angles $7.00 $13.00 Table 3: Outbound Transportation Costs per Unit in Single Centralized System Warehouse Atlanta Boston Chicago Dallas Los Angles Atlanta $13 Boston $16 $13 Chicago $16 $10 $13 Dallas $17 $17 $17 $13 Los Angles $19 $19 $18 $10 $13 Table 4: Ordering Cost and Holding Cost (per unit per week) Cost at Ordering Cost Current System (figure 1a) Regional Warehouse $5550 Central Warehouse (Figure 1b) Central Warehouse $5550 Mix Model (Figure 1c) Central Warehouse $3000 Regional Warehouse $3000 Holding Cost $1.25 $1.25 $1.00 $1.25 Management of KLF believes finding right distribution and corresponding inventory strategy is key to the cost savings. Which distribution model they should implement? Is it worth to switch from Continuous Review to Periodic Review inventory policy for sake of simplicity? What are other consideration apart from cost in selecting location for new warehouse? Would outsourcing inbound transportation good idea? Through analysis is required to find right inventory and distribution strategy. KLF Electronics - Project Questions Project Details: Read KLF electronics Project ( Taken and modified from Designing and Managing Supply Chain: Concepts, Strategies, and Case Studies by David Simchi-Levi, Philip Kaminsky, and Edith Simchi- Levi, Third Edition, McGraw Hill Publications) and perform through analysis. Maintaining service level of 90%, answer following questions in the format given at the end. Keep in mind case has lot more information and only few questions related to course material is included here. You may not need all information given in the case to answer questions. Questions: 1. Regional distributors are currently using continuous review inventory policy. Compute and describe their inventory management policy and associated cost. Ignore inbound and outbound transportation cost. Provide answers and calculation for order quantity, demand during lead time, safety stock, average inventory level, inventory holding cost per week, ordering cost per week and total cost per week. 2. KLF electronics evaluating potential for implementing periodic review inventory policy. However cost is primary consideration without compromising service level. Assuming that time between order (review period r) remains same as continuous review system for each regional warehouse, compute and describe its inventory management policy and associated cost for current distribution system (Figure 1a). Ignore inbound and outbound transportation cost. Provide answers and calculation for Base stock, safety stock, average inventory level, inventory holding cost per week, ordering cost per week and total cost per week. Compare your answers with answers obtained in question 1 and report percentage change in inventory holding cost per week, ordering cost per week and total cost per week for maintaining all the five regional warehouse. Comment on your findings. 3. Now consider transportation cost associated with distribution strategy. For distribution system given in figure la compute inbound and outbound transportation cost. Include these costs to total cost obtained in Questions 1. Comment on your findings. Completion Instructions: 1. Use 12 font size, single spacing, times new roman font. 2. Assignment should be 4 to 6 pages in length 3. Following format should be used. 4. Numbered references should be provide at the end and should be numbered where it is used. Report Format: Title page Not included in page length Analysis Answer questions 1 through 3. It should be very clear which question you are answering. You must use following table format. You can modify table to add more information but should not eliminate information. Question 1 Current Distribution Strategy (10)> Q* Ddlt SS Avg Inv Inv cost Ord Cost Tot Cost Atlanta Boston Chicago Dallas LA Total cost of the distribution system Question 2 Ord Cost Tot Cost Periodic Review Inventory Policy for Distribution strategy la > r Base Stock SS Avg Inv Inv cost Atlanta Boston Chicago Dallas LA Total cost of Periodic Review Policy for system 10 Total cost of Continuous Review Policy for system 1a Percentage Change in the cost Comment on the comparison > Question 3 Total of all Costs Transportation Cost for Distribution Strategy (10) > Inbound Outbound Holding+ Transportation Transportation Setup Cost Atlanta Boston Chicago Dallas LA Total cost of system la KLF Electronics KLF Electronics is an American manufacturer of electronic equipment. The company has a single manufacturing facility in San Jose, California. KLF Electronics distributes its products through five regional warehouses located in Atlanta, Boston, Chicago, Dallas, and Los Angeles. In the current distribution system, the United States is partitioned into five major markets, each of which is served by a single regional warehouse (see Figure 1a). Customers, typically retail outlets, receive items directly from the regional warehouse in their market. That is in the current distribution system, each customer is assigned to a single market and receives deliveries from one regional warehouse. The warehouses receive items from the manufacturing facility. In recent years, KLF has seen a significant increase in competition and huge pressure from their customers to improve the service level and reduce costs. KLF manages all its inbound transportation (manufacturing facility to warehouse). However, it is becoming increasing challenging to manage orders for different quantities, coming at different times from all 5 regional warehouses. Alternate Distribution Strategies There are different distribution strategy proposals are under consideration. First one is to replace in the five regional warehouses with a single, central warehouse that will be in charge of all customer (see Figure 1b). All the retailers will directly order from this central warehouse. This warehouse will be one of five current regional warehouses. This will also reduce complexity of order fulfillment and inbound transportation of manufacturing facility from five different to one warehouse. Currently, it takes two weeks to satisfy an order placed by any of the regional warehouses. KLF don't anticipate any different lead time for satisfying orders if one of these regional warehouse becomes central warehouse. Since Los Angles is only regional warehouse closure to manufacturing facility, another Central Warehouse could be added which will be in charge of Atlanta, Boston, Chicago, and Dallas (See figure 1c- Mix Model). Initial solution will be to find suitable location equidistance from these four cities. However there are other factors that will be considered in determining location. Manufacturing facility will serve Los Angles warehouse as usual in additional to central warehouse. KLF is also thinking of outsourcing task of order fulfillment, all inbound and intermediate logistics (Manufacturing facility to Los Angles and Central Warehouse, Central Warehouse to Atlanta, Boston, Chicago, & Dallas warehouses) to a third party logistics provider (3PL) which specialize in logistics and distribution services. This company can provide service at lower cost and shorter lead-times from two week to one week for each segment of inbound and intermediate transportation needs. Overhead costs of maintaining inbound transportation department could offset cost of adding new central warehouse in long term. Figure 1: Distribution Strategies --Current and proposed Manufacturing Facility Regional or Central Warehouse Retailer a) Current Model b) Single Centralized Warehouse c) Mix Model of Regional and Central Warehouse Demand and Inventory Management Strategy Each of the regional warehouses faces demand from the retailers in their area. Historical demand for last 12 weeks is given in the Table 1. This sample of 12 weeks is very much representative of demand pattern that they face. Currently, all regional warehouses uses continuous review inventory policy where order for fixed quantity is placed when inventory level falls below reorder point. This leads to orders coming at different times in the manufacturing facility which typically satisfy orders in 2 weeks. KLF provides their customers with a service level of about 90 percent. It is striving to improve that but cost savings without affecting service level is primary goal for now. KLF also wants to evaluate possibility of implementing Periodic Review Inventory Policy (potentially in future they can synchronize ordering time). However decision is sensitive and dependent on change in the inventory cost. Table 1: Historical Demand for 12 weeks Week11 Week 1 33 26 Week 2 45 35 Week 3 37 Week 4 38 Weeks 55 Week 6 30 Week9 47 Week 10 37 Week 12 55 41 40 48 62 44 45 Atlanta Boston Chicago Dallas LA 46 48 34 Week7 Week 18 58 55 18 62 28 70 65 40 35 72 27 95 44 27 22 35 883 U 60 8868 45 55 40 40 % 30 35 38 42 51 64 55 43 47 32 43 54 46 74 45 38 48 56 * Transportation, Ordering, and Holding Costs Currently with inbound transportation there is fixed ordering cost per order plus a variable transportation cost associated with it. For outbound transportation (regional warehouse to retailer) orders, which are typically much smaller in quantity, there is only variable transportation cost. Table 2 provides inbound and outbound transportation cost associated with current distribution system. Table 3 provides information about (outbound) transportation costs per unit product from each existing regional warehouse to all other market areas, assuming this regional warehouse becomes the central warehouse as described in figure 1b. In case if KLF decides to add central warehouse to serve Atlanta, Boston, Chicago and Dallas regional warehouses, 3PL provider has agreed to provide similar cost model, i.e. fixed ordering cost per order and variable transportation cost per unit ordered. Transportation cost quoted by 3PL from manufacturing facility to new warehouse (or Los Angles) is $10 and from new warehouse to other four regional warehouse is $6. Table 4 provides ordering cost per order associated with current, single centralized warehouse and mix model distribution system. Corresponding holding cost is also given. Table 2: Inbound and Outbound Transportation Costs per Unit with Current System Warehouse Inbound Outbound Atlanta $12.00 $13.00 Boston $11.50 $13.00 Chicago $11.00 $13.00 Dallas $9.00 $13.00 Los Angles $7.00 $13.00 Table 3: Outbound Transportation Costs per Unit in Single Centralized System Warehouse Atlanta Boston Chicago Dallas Los Angles Atlanta $13 Boston $16 $13 Chicago $16 $10 $13 Dallas $17 $17 $17 $13 Los Angles $19 $19 $18 $10 $13 Table 4: Ordering Cost and Holding Cost (per unit per week) Cost at Ordering Cost Current System (figure 1a) Regional Warehouse $5550 Central Warehouse (Figure 1b) Central Warehouse $5550 Mix Model (Figure 1c) Central Warehouse $3000 Regional Warehouse $3000 Holding Cost $1.25 $1.25 $1.00 $1.25 Management of KLF believes finding right distribution and corresponding inventory strategy is key to the cost savings. Which distribution model they should implement? Is it worth to switch from Continuous Review to Periodic Review inventory policy for sake of simplicity? What are other consideration apart from cost in selecting location for new warehouse? Would outsourcing inbound transportation good idea? Through analysis is required to find right inventory and distribution strategy. KLF Electronics - Project Questions Project Details: Read KLF electronics Project ( Taken and modified from Designing and Managing Supply Chain: Concepts, Strategies, and Case Studies by David Simchi-Levi, Philip Kaminsky, and Edith Simchi- Levi, Third Edition, McGraw Hill Publications) and perform through analysis. Maintaining service level of 90%, answer following questions in the format given at the end. Keep in mind case has lot more information and only few questions related to course material is included here. You may not need all information given in the case to answer questions. Questions: 1. Regional distributors are currently using continuous review inventory policy. Compute and describe their inventory management policy and associated cost. Ignore inbound and outbound transportation cost. Provide answers and calculation for order quantity, demand during lead time, safety stock, average inventory level, inventory holding cost per week, ordering cost per week and total cost per week. 2. KLF electronics evaluating potential for implementing periodic review inventory policy. However cost is primary consideration without compromising service level. Assuming that time between order (review period r) remains same as continuous review system for each regional warehouse, compute and describe its inventory management policy and associated cost for current distribution system (Figure 1a). Ignore inbound and outbound transportation cost. Provide answers and calculation for Base stock, safety stock, average inventory level, inventory holding cost per week, ordering cost per week and total cost per week. Compare your answers with answers obtained in question 1 and report percentage change in inventory holding cost per week, ordering cost per week and total cost per week for maintaining all the five regional warehouse. Comment on your findings. 3. Now consider transportation cost associated with distribution strategy. For distribution system given in figure la compute inbound and outbound transportation cost. Include these costs to total cost obtained in Questions 1. Comment on your findings. Completion Instructions: 1. Use 12 font size, single spacing, times new roman font. 2. Assignment should be 4 to 6 pages in length 3. Following format should be used. 4. Numbered references should be provide at the end and should be numbered where it is used. Report Format: Title page Not included in page length Analysis Answer questions 1 through 3. It should be very clear which question you are answering. You must use following table format. You can modify table to add more information but should not eliminate information. Question 1 Current Distribution Strategy (10)> Q* Ddlt SS Avg Inv Inv cost Ord Cost Tot Cost Atlanta Boston Chicago Dallas LA Total cost of the distribution system Question 2 Ord Cost Tot Cost Periodic Review Inventory Policy for Distribution strategy la > r Base Stock SS Avg Inv Inv cost Atlanta Boston Chicago Dallas LA Total cost of Periodic Review Policy for system 10 Total cost of Continuous Review Policy for system 1a Percentage Change in the cost Comment on the comparison > Question 3 Total of all Costs Transportation Cost for Distribution Strategy (10) > Inbound Outbound Holding+ Transportation Transportation Setup Cost Atlanta Boston Chicago Dallas LA Total cost of system la