Question: Use the stock-control model to develop a spread sheet simulation for one year 12 months to find, monthly Revenue, Production Cost, Order Cost, Purchase Cost,

Use the stock-control model to develop a spread sheet simulation for one year 12 months to find, monthly Revenue, Production Cost, Order Cost, Purchase Cost, Holding Cost, Shortage Cost, Total Cost and Profit.

Use the stock-control model to develop a spread sheet simulation for one year 12 months to find, monthly Revenue, Production Cost, Order Cost, Purchase Cost, Holding Cost, Shortage Cost, Total Cost and Profit.- Which supplier is the best in term of the probability the store gain and the probability the store gain loss? Why?

- Which policy is the best and why? In term of Holding Cost, Shortage Cost, Order Cost, Total Cost.

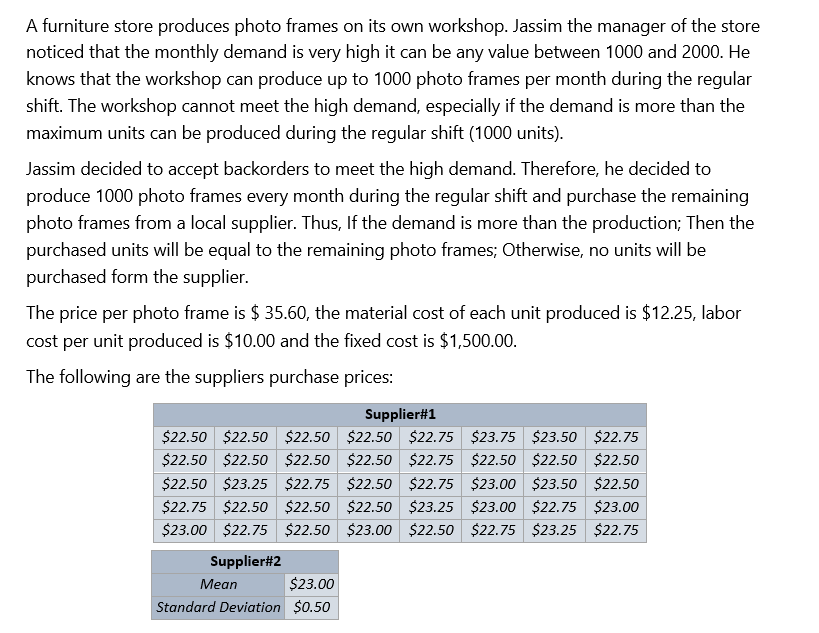

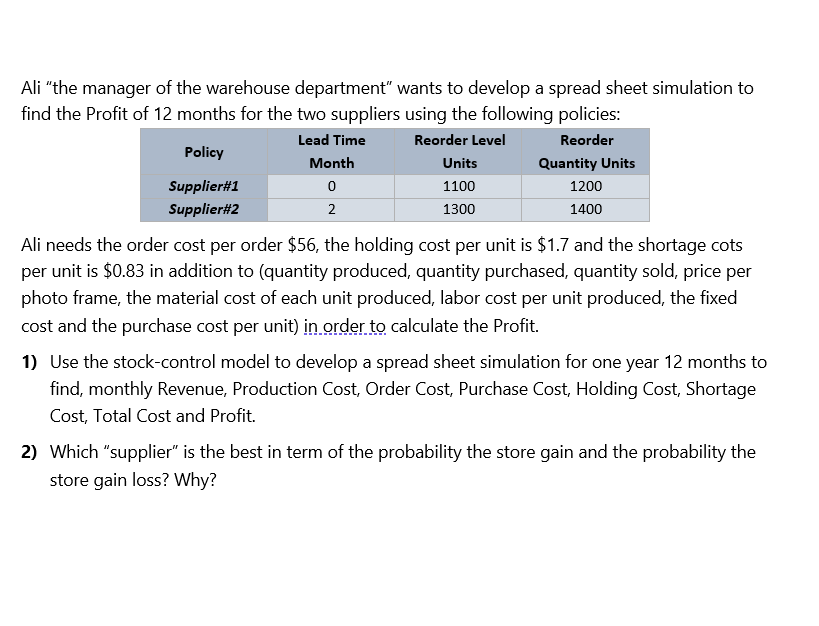

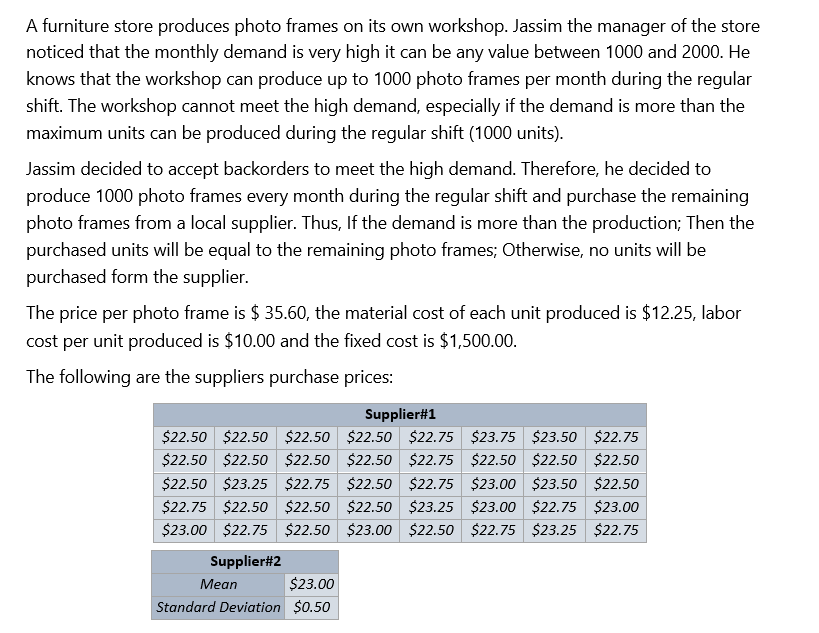

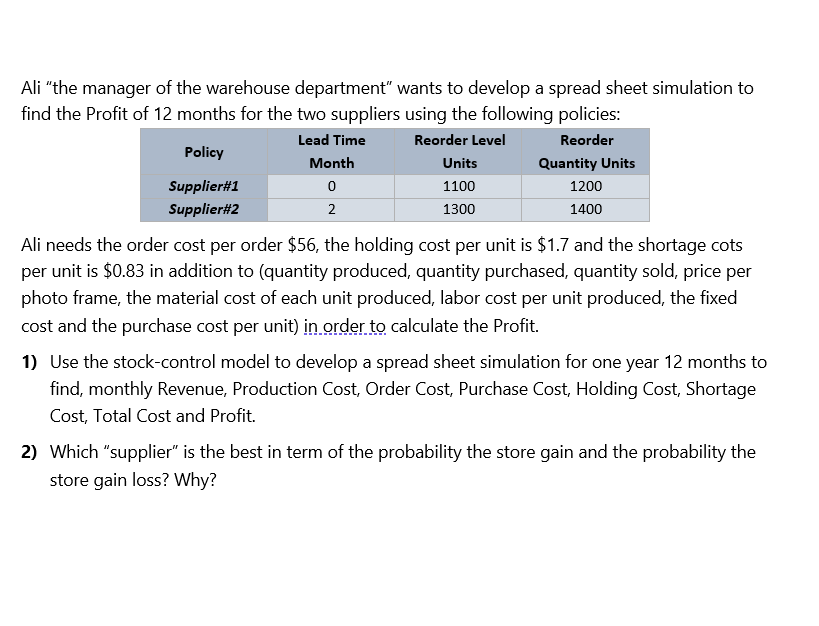

Ali "the manager of the warehouse department" wants to develop a spread sheet simulation to find the Profit of 12 months for the two suppliers using the following policies: Lead Time Reorder Level Reorder Policy Month Units Quantity Units Supplier#1 0 1100 1200 Supplier#2 2 1300 1400 Ali needs the order cost per order $56, the holding cost per unit is $1.7 and the shortage cots per unit is $0.83 in addition to (quantity produced, quantity purchased, quantity sold, price per photo frame, the material cost of each unit produced, labor cost per unit produced, the fixed cost and the purchase cost per unit) in order to calculate the Profit. 1) Use the stock-control model to develop a spread sheet simulation for one year 12 months to find, monthly Revenue, Production Cost, Order Cost, Purchase Cost, Holding Cost, Shortage Cost, Total Cost and Profit. 2) Which "supplier" is the best in term of the probability the store gain and the probability the store gain loss? Why? A furniture store produces photo frames on its own workshop. Jassim the manager of the store noticed that the monthly demand is very high it can be any value between 1000 and 2000. He knows that the workshop can produce up to 1000 photo frames per month during the regular shift. The workshop cannot meet the high demand, especially if the demand is more than the maximum units can be produced during the regular shift (1000 units). Jassim decided to accept backorders to meet the high demand. Therefore, he decided to produce 1000 photo frames every month during the regular shift and purchase the remaining photo frames from a local supplier. Thus, If the demand is more than the production; Then the purchased units will be equal to the remaining photo frames; Otherwise, no units will be purchased form the supplier. The price per photo frame is $ 35.60, the material cost of each unit produced is $12.25, labor cost per unit produced is $10.00 and the fixed cost is $1,500.00. The following are the suppliers purchase prices: Supplier#1 $22.50 $22.50 $22.50 $22.50 $22.75 $23.75 $23.50 $22.75 $22.50 $22.50 $22.50 $22.50 $22.75 $22.50 $22.50 $22.50 $22.50 $23.25 $22.75 $22.50 $22.75 $23.00 $23.50 $22.50 $22.75 $22.50 $22.50 $22.50 $23.25 $23.00 $22.75 $23.00 $23.00 $22.75 $22.50 $23.00 $22.50 $22.75 $23.25 $22.75 Supplier#2 Mean $23.00 Standard Deviation $0.50 Ali "the manager of the warehouse department" wants to develop a spread sheet simulation to find the Profit of 12 months for the two suppliers using the following policies: Lead Time Reorder Level Reorder Policy Month Units Quantity Units Supplier#1 0 1100 1200 Supplier#2 2 1300 1400 Ali needs the order cost per order $56, the holding cost per unit is $1.7 and the shortage cots per unit is $0.83 in addition to (quantity produced, quantity purchased, quantity sold, price per photo frame, the material cost of each unit produced, labor cost per unit produced, the fixed cost and the purchase cost per unit) in order to calculate the Profit. 1) Use the stock-control model to develop a spread sheet simulation for one year 12 months to find, monthly Revenue, Production Cost, Order Cost, Purchase Cost, Holding Cost, Shortage Cost, Total Cost and Profit. 2) Which "supplier" is the best in term of the probability the store gain and the probability the store gain loss? Why? A furniture store produces photo frames on its own workshop. Jassim the manager of the store noticed that the monthly demand is very high it can be any value between 1000 and 2000. He knows that the workshop can produce up to 1000 photo frames per month during the regular shift. The workshop cannot meet the high demand, especially if the demand is more than the maximum units can be produced during the regular shift (1000 units). Jassim decided to accept backorders to meet the high demand. Therefore, he decided to produce 1000 photo frames every month during the regular shift and purchase the remaining photo frames from a local supplier. Thus, If the demand is more than the production; Then the purchased units will be equal to the remaining photo frames; Otherwise, no units will be purchased form the supplier. The price per photo frame is $ 35.60, the material cost of each unit produced is $12.25, labor cost per unit produced is $10.00 and the fixed cost is $1,500.00. The following are the suppliers purchase prices: Supplier#1 $22.50 $22.50 $22.50 $22.50 $22.75 $23.75 $23.50 $22.75 $22.50 $22.50 $22.50 $22.50 $22.75 $22.50 $22.50 $22.50 $22.50 $23.25 $22.75 $22.50 $22.75 $23.00 $23.50 $22.50 $22.75 $22.50 $22.50 $22.50 $23.25 $23.00 $22.75 $23.00 $23.00 $22.75 $22.50 $23.00 $22.50 $22.75 $23.25 $22.75 Supplier#2 Mean $23.00 Standard Deviation $0.50

Use the stock-control model to develop a spread sheet simulation for one year 12 months to find, monthly Revenue, Production Cost, Order Cost, Purchase Cost, Holding Cost, Shortage Cost, Total Cost and Profit.

Use the stock-control model to develop a spread sheet simulation for one year 12 months to find, monthly Revenue, Production Cost, Order Cost, Purchase Cost, Holding Cost, Shortage Cost, Total Cost and Profit.