Question: Using a spreadsheet and based on the information provided in the next section, complete the following requirements: 1 . Determine the predetermined overhead rate. 2

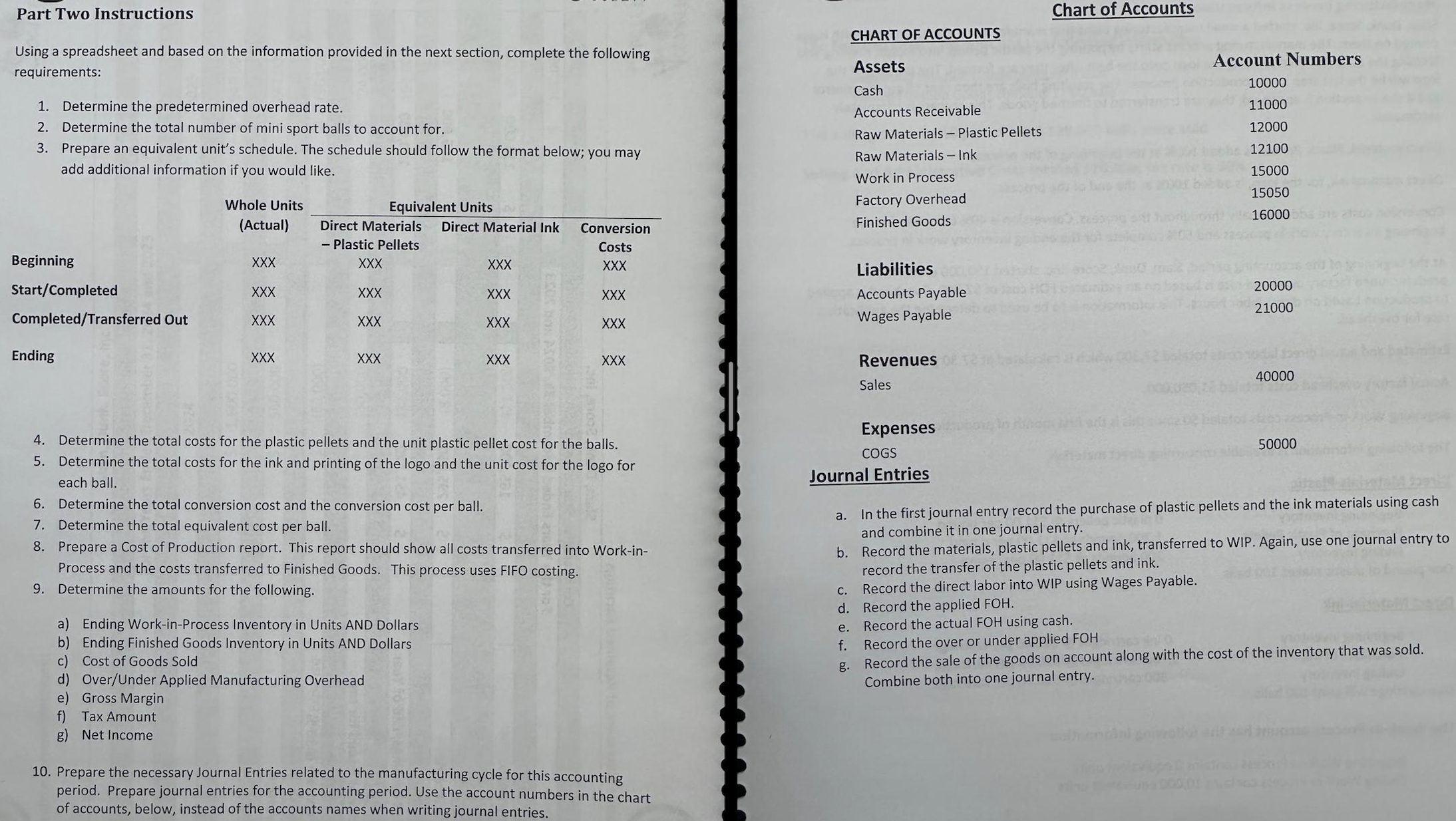

Using a spreadsheet and based on the information provided in the next section, complete the following requirements: Determine the predetermined overhead rate. Determine the total number of mini sport balls to account for. Prepare an equivalent unit's schedule. The schedule should follow the format below; you may add additional information if you would like. Whole Units Actual Equivalent Units Direct MaterialPlastic pallets Direct MaterialInk Conversion Costs Beginning StartCompleted CompletedTransferred Out Ending Determine the total costs for the plastic pellets and the unit plastic pellet cost for the balls. Determine the total costs for the ink and printing of the logo and the unit cost for the logo for each ball. Determine the total conversion cost and the conversion cost per ball. Determine the total equivalent cost per ball. Prepare a Cost of Production report. This report should show all costs transferred into WorkinProcess and the costs transferred to Finished Goods. This process uses FIFO costing. Determine the amounts for the following. a Ending WorkinProcess Inventory in Units AND Dollars b Ending Finished Goods Inventory in Units AND Dollars CCost of Goods Sold d OverUnder Applied Manufacturing Overhead eGross Margin fTax Amount g Net Income Prepare the necessary Journal Entries related to the manufacturing cycle for this accounting period. Prepare journal entries for the accounting period. Use the account numbers in the chart of accounts, below, instead of the accounts names when writing journal entries. CHART OF ACCOUNTS Assets Account Numbers Cash Accounts Receivable Raw Materials Plastic Pellets Raw Materials Ink Work in Process Factory Overhead Finished Goods Liabilities Accounts Payable Wages Payable Revenues Sales Expenses COGS Journal Entries a In the first journal entry record the purchase of plastic pellets and the ink materials using cash and combine it in one journal entry. b Record the materials, plastic pellets and ink, transferred to WIP. Again, use one journal entry to record the transfer of the plastic pellets and ink. C Record the direct labor into WIP using Wages Payable. d Record the applied FOH. e Record the actual FOH using cash. f Record the over or under applied FOH g Record the sale of the goods on account along with the cost of the inventory that was sold. Combine both into one journal entry. Manufacturing Process Information Slam, Dunk, Score, Inc. started a small manufacturing plant that manufactures mini sport balls with logos printed on them. The manufacturing process starts by pouring the plastic pellets into molds, melting and forming the balls and then printing the logo onto the balls after they are formed. The printing of the logo will be the last step in the production process. The resulting balls are then sent to quality control and if the inspection is approved, they are transferred to finished goods. This process is completely automated. Direct material, Plastic Pellets, is added at the beginning of the process.Direct material ink, for the logo is added at the end of the process. Conversion costs are added equally throughout the process. Conversion is complete for the beginning inventory work in process and complete for the ending inventory work in process. At the beginning of the accounting period, Slam, Dunk, Score, Inc. started units. The predetermined factory overhead rate is based on an estimated FOH cost of $ Overhead is applied to production based on direct labor hours. This information is to be used to determine the application rate for overhead. Estimated and actual direct labor costs totaled $ which is calculated at $ per hour. Actual factory overhead costs totaled $ Beginning WorkinProcess costs totaled $ since this is the first month of production. The following information is available concerning direct materials. Direct MaterialsPlastic Beginning inventory plastic pellets @ $ per pound Purchase of Plastic Pellets pounds @ $ per pound Ending Inventory pounds @ $ per pound One pound of plastic makes balls Direct MaterialInk Beginning inventory ink cartridges @ $ per cartridge Purchases of Ink cartridges @ $ per cartridge Ending inventory cartridges @ $ per cartridge One cartridge will print balls The WorkinProcess account has the following information Beginning WorkinProcess contains equivalent units Ending WorkinProcess contains equivalent units The Finished Goods account has the following Information Beginning Finished Goods contains balls Ending Finished Goods contains balls The selling price is $ per ball and balls were sold Selling and Administrative Costs totaled $; Tax rate

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock