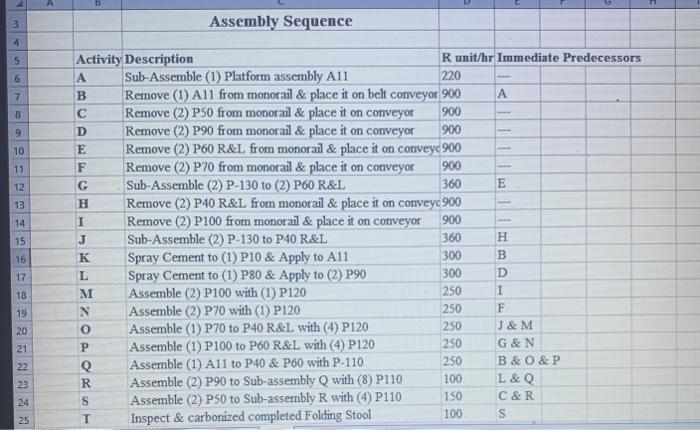

Question: Using line balancing and work/operation analysis. Based upon the following data, develop your recommended allocation of work and the number of workstations. A 3 Assembly

A 3 Assembly Sequence 4 S 6 7 8 9 10 11 12 13 14 I 900 15 16 Activity Description R unit/hr Immediate Predecessors A Sub-Assemble (1) Platform assembly All 220 B Remove (1) A11 from monorail & place it on belt conveyor 900 A C Remove (2) P50 from monorail & place it on conveyor 900 D Remove (2) P90 from monorail & place it on conveyor 900 E Remove (2) P60 R&L from monorail & place it on conveyc 900 F Remove (2) P70 from monorail & place it on conveyor 900 G Sub-Assemble (2) P-130 to (2) P60 R&L 360 E H Remove (2) P40 R&L from monorail & place it on convey 900 Remove (2) P100 from monorail & place it on conveyor J Sub-Assemble (2) P-130 to P40 R&L 360 H K Spray Cement to (1) P10 & Apply to A11 300 B L Spray Cement to (1) P80 & Apply to (2) P90 300 M Assemble (2) P100 with (1) P120 250 I N Assemble (2) P70 with (1) P120 250 0 Assemble (1) P70 to P40 R&L with (4) P120 250 J & M P Assemble (1) P100 to P60 R&L with (4) P120 250 G&N Assemble (1) All to P40 & P60 with P-110 250 B&O & P R Assemble (2) P90 to Sub-assembly Q with (8) P110 L&Q S Assemble (2) P50 to Sub-assembly R with (4) P110 150 C&R T Inspect & carbonized completed Folding Stool 100 S 17 D 18 F 19 20 21 100 22 23 24 25

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts