Question: Using the BSG Simulation Online my group and I managed to meet expectations besides image rating. We did so by just changing numbers pretty randomly

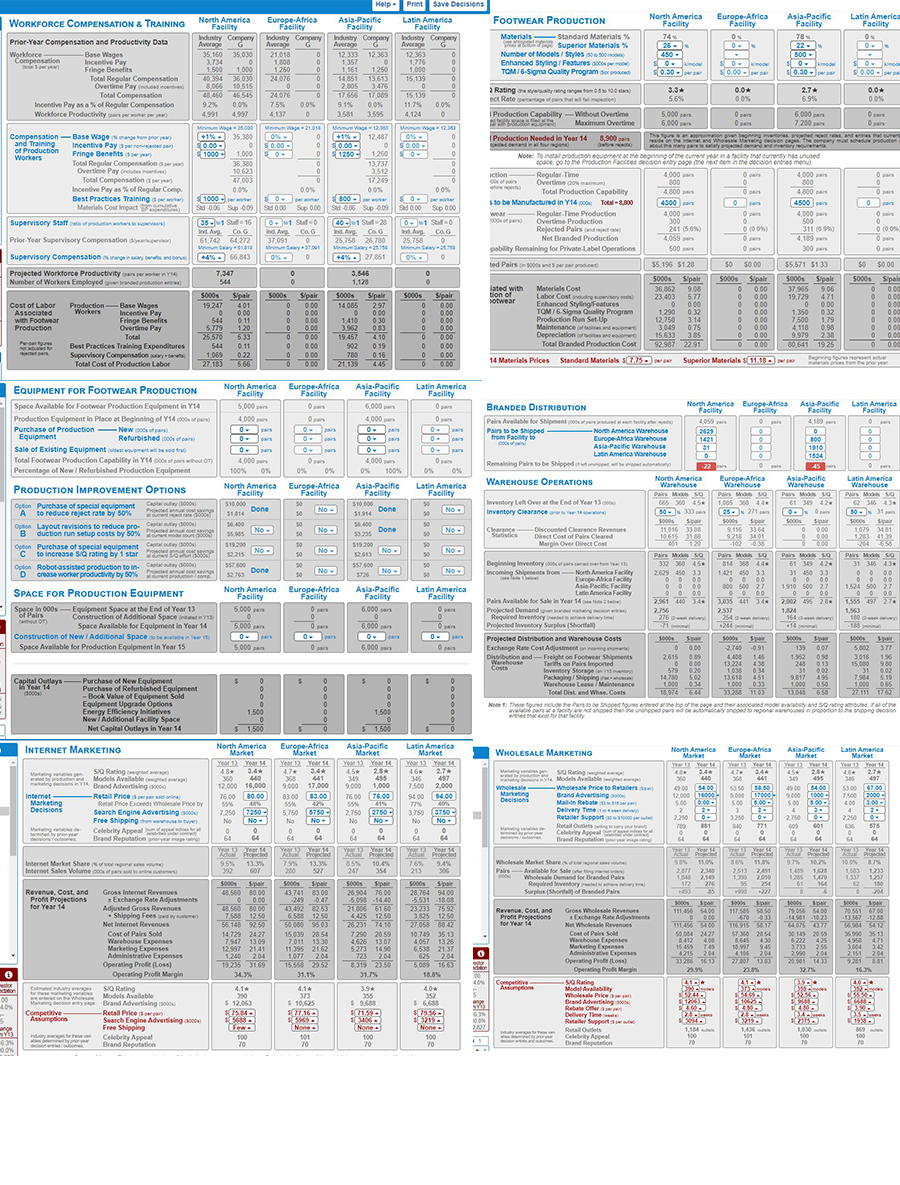

Using the BSG Simulation Online my group and I managed to meet expectations besides image rating. We did so by just changing numbers pretty randomly to be honest. I've asked questions about BSG in the past and some answers were helpful but still pretty confusing. I appreciate answers like those that have told us that increasing variable costs only instead of fixed can improve ending revenue, but I would appreciate a more focused answer, on what numbers to change exactly? I added a picture below of all our options; we changed many options but did so randomly, can anyone provide any tips so we can become more coordinated with our adjustments lol, thank you!

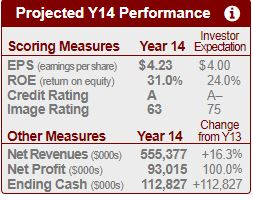

Projected Y14 Performance i Investor Scoring Measures Year 14 Expectation EPS (eamings pershare) $4.23 $4.00 ROE (retum on equity) 31.0% 24.0% Credit Rating Image Rating 63 Change Other Measures Year 14 from Y13 Net Revenues (5000s) 555,377 +16.3% Net Profit (5000s) 93,015 100.0% Ending Cash (5000s) 112,827 +112,827 Help- Asia-Pacific Print Save Decisions Latin America Facility TRAINING North America Europe Africa Facility North America Facility WORKFORCE COMPENSATION FOOTWEAR PRODUCTION Europe, Africa Facility Asia-Pacific Facility Latin America Facility Facility y Com wy Industry Cory 35.100 35030 Awad 21.018 12.333 12 363 12 353 Materials Standard Materials % Superior Materials Number of Models Styles Enhanced Styling Features TOM / 6-Sigma Quality Program Ice Pay 50- S0.30 - 50- 6 .00 0.30 1 Prior-Year Compensation and Productivity Data Workforce - Base Wages Fringe Benefits Total Regular Compensation Overtime Pay Total Compensation Incentive Pay as of Regular Compensation Workforce Productivity 3336 16 851 13 613 0.0* 176 1700 Rating w as ect Rate of Production Capability Without Overtime Maximum Overtime 6,000 cars 5.000 6.000 +1% 12.487 Production Needed in Year 14 8.900 Compensation and Training of Production Workers 1260 curre neem d Base Wage ) Incentive Pay ) Fringe Benefits Total Regular Compensation Overtime Pays ) Total Compensation Incentive Pay as % of Regular Com Best Practices Training Mads Cost Impact 1000 800 Nos production at the beging of the curren t 0 Production C on t ent in the iction Regular Time Overtime Total Production Capability to be Manufactured in Y14 T UNO 4300 Regular Time Product DOO Over Production Relected Pairs Net Branded Production pabay Remaining for Private Label Operations Supervisory Staff 40 And Ave. Su 25 Cat Prior Year Supervisory Compensation 61726272 Supervisory Compensation 4 66,343 24%. 27.851 bed Pairs Projected Workforce Productivity Number of Workers Employed 5000 Spal lated with Sipar woer Cost of Labor Production Base Wipes Materials Cost Labor Cost Enhanced Styling Features TOMISO Program Production Run Set Up with Footwear Production Fringe Benefits Overtime Pay Tool Best Practices Training Expenditures Supervisory Compensowy Total cost of Production Labor Depec Total Branded Production Cost 14 Materials Prices Standard Materials 2251 Superior Materials $11.130 32 2205 Decem b er Africa North America Asia-Pacific EQUIPMENT FOR FOOTWEAR PRODUCTION Latin America BRANDED DISTRIBUTION North America Europe Africa Asia Pacific America Space Awable for Footwear Production Equipment Y14 Production Equipments Place of Y16 Purchase of Production News Equipment Refurbished 200 Sale of Existing Equipment Total Footwear Production Capability in Y14 Percentage of New Refurbished Production Equipment Pairs to be shipped from Facy Europeica Who Remaining Pairs to be shipped out WAREHOUSE OPERATIONS Nom Warehouse Warehouse se Warehouse European Africa Asia Pacific the year 13 NO Inventory Over Inventory Clearance PRODUCTION IMPROVEMENT OPTIONS Option Purchase of special equipment A to reduce reject rate by 50% Option Layout revisions to reduce pro B duction run setup costs by 50% Option Purchase of special equipment C to increase so rating by 1 star C Option Robot-assisted production to in D crease worlar productivity by 50% NO Done NO Statistics -Discounted Clearance Reves Direct Cost of Pairs Cleared Marga Over De Cost NO NO NO NO 557.600 Incoming Shipment from North A rka Facy Europe Akalay North America Facility Eur Europe Africa Asta Pacific Latin America 6,000 SPACE FOR PRODUCTION EQUIPMENT Spacin 00s - Equipment Space at the End of Year 13 Construction of Additional Space Space Available for Equipment in Year 14 Construction of New Additional Space Space Available for Production Equipment in Year 15 America Pair Aviate for Sale in Year 16 Protected Demand Required Inventory Projected Inventory Surplus Short Projected Distribution and Warehouse Costs Exchange Rate Cost Adjustment Distribution and Freight on Footwear Spments Costs 0. 0 Capital Olays Year Purchase of New Equine Total Distand Whis. Costs Purchase of Refurbished Equipment -Book Value of Equipement Sold Equipment Upgrade Options Energy Efficiency l atives New Additional Face Space Net Capital Outlays in Year 14 Europe Africa AsiaPacific INTERNET MARKETING WHOLESALE MARKETING North America Europe Ac c ife America Models Awit wers R Price O 0000 Search Engine Advertising Free Song Celebrity Appeal Brude CA bernet Sales Volume for Sale Surplus Sharof Branded Pars Revenue, Cost and Profit Projections Reven. Cost and Exchange Rate M e 500 550 Groentent Revenge Exchange Rate M Adjusted GrossRevens - Shipping Fees Net Internet Revens Cost of Pairs Sold Warehouse Expenses Marketing L es Adestrative Expenses Operating ProLoss) Operating Profit Margia Costo Pin 11.395 2162 pens Operating Profess) Operating ProMar w SIQ Rating Models Available Brand Advertising Recall Prices Search Engine Advertising Free Shipping Celebrity Appeal $ 12,063 0580 . 172.16 . Projected Y14 Performance i Investor Scoring Measures Year 14 Expectation EPS (eamings pershare) $4.23 $4.00 ROE (retum on equity) 31.0% 24.0% Credit Rating Image Rating 63 Change Other Measures Year 14 from Y13 Net Revenues (5000s) 555,377 +16.3% Net Profit (5000s) 93,015 100.0% Ending Cash (5000s) 112,827 +112,827 Help- Asia-Pacific Print Save Decisions Latin America Facility TRAINING North America Europe Africa Facility North America Facility WORKFORCE COMPENSATION FOOTWEAR PRODUCTION Europe, Africa Facility Asia-Pacific Facility Latin America Facility Facility y Com wy Industry Cory 35.100 35030 Awad 21.018 12.333 12 363 12 353 Materials Standard Materials % Superior Materials Number of Models Styles Enhanced Styling Features TOM / 6-Sigma Quality Program Ice Pay 50- S0.30 - 50- 6 .00 0.30 1 Prior-Year Compensation and Productivity Data Workforce - Base Wages Fringe Benefits Total Regular Compensation Overtime Pay Total Compensation Incentive Pay as of Regular Compensation Workforce Productivity 3336 16 851 13 613 0.0* 176 1700 Rating w as ect Rate of Production Capability Without Overtime Maximum Overtime 6,000 cars 5.000 6.000 +1% 12.487 Production Needed in Year 14 8.900 Compensation and Training of Production Workers 1260 curre neem d Base Wage ) Incentive Pay ) Fringe Benefits Total Regular Compensation Overtime Pays ) Total Compensation Incentive Pay as % of Regular Com Best Practices Training Mads Cost Impact 1000 800 Nos production at the beging of the curren t 0 Production C on t ent in the iction Regular Time Overtime Total Production Capability to be Manufactured in Y14 T UNO 4300 Regular Time Product DOO Over Production Relected Pairs Net Branded Production pabay Remaining for Private Label Operations Supervisory Staff 40 And Ave. Su 25 Cat Prior Year Supervisory Compensation 61726272 Supervisory Compensation 4 66,343 24%. 27.851 bed Pairs Projected Workforce Productivity Number of Workers Employed 5000 Spal lated with Sipar woer Cost of Labor Production Base Wipes Materials Cost Labor Cost Enhanced Styling Features TOMISO Program Production Run Set Up with Footwear Production Fringe Benefits Overtime Pay Tool Best Practices Training Expenditures Supervisory Compensowy Total cost of Production Labor Depec Total Branded Production Cost 14 Materials Prices Standard Materials 2251 Superior Materials $11.130 32 2205 Decem b er Africa North America Asia-Pacific EQUIPMENT FOR FOOTWEAR PRODUCTION Latin America BRANDED DISTRIBUTION North America Europe Africa Asia Pacific America Space Awable for Footwear Production Equipment Y14 Production Equipments Place of Y16 Purchase of Production News Equipment Refurbished 200 Sale of Existing Equipment Total Footwear Production Capability in Y14 Percentage of New Refurbished Production Equipment Pairs to be shipped from Facy Europeica Who Remaining Pairs to be shipped out WAREHOUSE OPERATIONS Nom Warehouse Warehouse se Warehouse European Africa Asia Pacific the year 13 NO Inventory Over Inventory Clearance PRODUCTION IMPROVEMENT OPTIONS Option Purchase of special equipment A to reduce reject rate by 50% Option Layout revisions to reduce pro B duction run setup costs by 50% Option Purchase of special equipment C to increase so rating by 1 star C Option Robot-assisted production to in D crease worlar productivity by 50% NO Done NO Statistics -Discounted Clearance Reves Direct Cost of Pairs Cleared Marga Over De Cost NO NO NO NO 557.600 Incoming Shipment from North A rka Facy Europe Akalay North America Facility Eur Europe Africa Asta Pacific Latin America 6,000 SPACE FOR PRODUCTION EQUIPMENT Spacin 00s - Equipment Space at the End of Year 13 Construction of Additional Space Space Available for Equipment in Year 14 Construction of New Additional Space Space Available for Production Equipment in Year 15 America Pair Aviate for Sale in Year 16 Protected Demand Required Inventory Projected Inventory Surplus Short Projected Distribution and Warehouse Costs Exchange Rate Cost Adjustment Distribution and Freight on Footwear Spments Costs 0. 0 Capital Olays Year Purchase of New Equine Total Distand Whis. Costs Purchase of Refurbished Equipment -Book Value of Equipement Sold Equipment Upgrade Options Energy Efficiency l atives New Additional Face Space Net Capital Outlays in Year 14 Europe Africa AsiaPacific INTERNET MARKETING WHOLESALE MARKETING North America Europe Ac c ife America Models Awit wers R Price O 0000 Search Engine Advertising Free Song Celebrity Appeal Brude CA bernet Sales Volume for Sale Surplus Sharof Branded Pars Revenue, Cost and Profit Projections Reven. Cost and Exchange Rate M e 500 550 Groentent Revenge Exchange Rate M Adjusted GrossRevens - Shipping Fees Net Internet Revens Cost of Pairs Sold Warehouse Expenses Marketing L es Adestrative Expenses Operating ProLoss) Operating Profit Margia Costo Pin 11.395 2162 pens Operating Profess) Operating ProMar w SIQ Rating Models Available Brand Advertising Recall Prices Search Engine Advertising Free Shipping Celebrity Appeal $ 12,063 0580 . 172.16

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts