Question: Using the Excel template provided, prepare a report showing the reciprocal method of allocation of support costs to production departments. Use the Excel Solver Add-In

- Using the Excel template provided, prepare a report showing the reciprocal method of allocation of support costs to production departments. Use the Excel Solver Add-In to assist in calculating the allocation

I need help with this one please

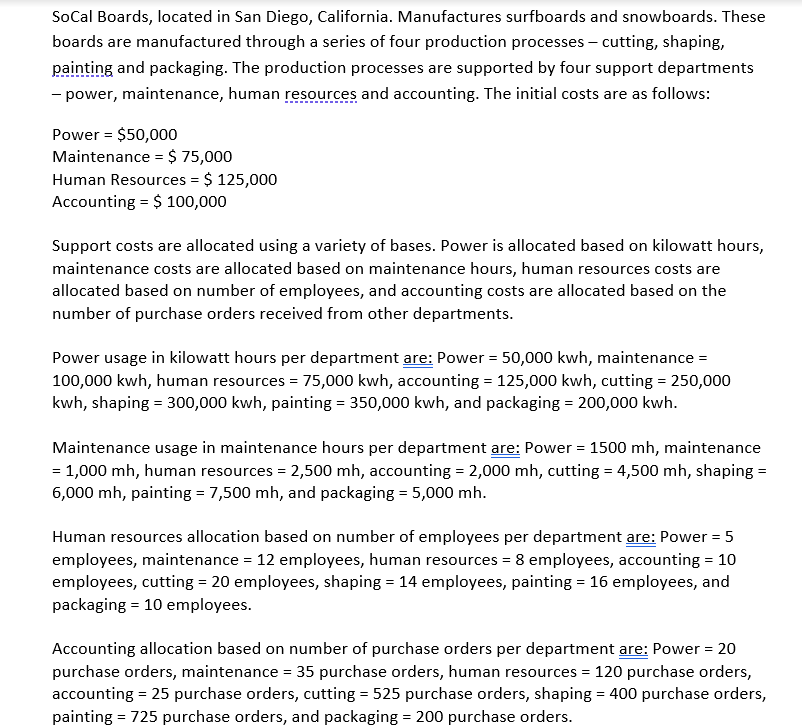

SoCal Boards, located in San Diego, California. Manufactures surfboards and snowboards. These boards are manufactured through a series of four production processes - cutting, shaping, painting and packaging. The production processes are supported by four support departments - power, maintenance, human resources and accounting. The initial costs are as follows: Power = $50,000 Maintenance = $ 75,000 Human Resources = $ 125,000 Accounting = $ 100,000 Support costs are allocated using a variety of bases. Power is allocated based on kilowatt hours, maintenance costs are allocated based on maintenance hours, human resources costs are allocated based on number of employees, and accounting costs are allocated based on the number of purchase orders received from other departments. Power usage in kilowatt hours per department are: Power = 50,000 kwh, maintenance = 100,000 kwh, human resources = 75,000 kwh, accounting = 125,000 kwh, cutting = 250,000 kwh, shaping = 300,000 kwh, painting = 350,000 kwh, and packaging = 200,000 kwh. Maintenance usage in maintenance hours per department are: Power = 1500 mh, maintenance = 1,000 mh, human resources = 2,500 mh, accounting = 2,000 mh, cutting = 4,500 mh, shaping = 6,000 mh, painting = 7,500 mh, and packaging = 5,000 mh. Human resources allocation based on number of employees per department are: Power = 5 employees, maintenance = 12 employees, human resources = 8 employees, accounting = 10 employees, cutting = 20 employees, shaping = 14 employees, painting = 16 employees, and packaging = 10 employees. Accounting allocation based on number of purchase orders per department are: Power = 20 purchase orders, maintenance = 35 purchase orders, human resources = 120 purchase orders, accounting = 25 purchase orders, cutting = 525 purchase orders, shaping = 400 purchase orders, painting = 725 purchase orders, and packaging = 200 purchase orders. = = SoCal Boards, located in San Diego, California. Manufactures surfboards and snowboards. These boards are manufactured through a series of four production processes - cutting, shaping, painting and packaging. The production processes are supported by four support departments - power, maintenance, human resources and accounting. The initial costs are as follows: Power = $50,000 Maintenance = $ 75,000 Human Resources = $ 125,000 Accounting = $ 100,000 Support costs are allocated using a variety of bases. Power is allocated based on kilowatt hours, maintenance costs are allocated based on maintenance hours, human resources costs are allocated based on number of employees, and accounting costs are allocated based on the number of purchase orders received from other departments. Power usage in kilowatt hours per department are: Power = 50,000 kwh, maintenance = 100,000 kwh, human resources = 75,000 kwh, accounting = 125,000 kwh, cutting = 250,000 kwh, shaping = 300,000 kwh, painting = 350,000 kwh, and packaging = 200,000 kwh. Maintenance usage in maintenance hours per department are: Power = 1500 mh, maintenance = 1,000 mh, human resources = 2,500 mh, accounting = 2,000 mh, cutting = 4,500 mh, shaping = 6,000 mh, painting = 7,500 mh, and packaging = 5,000 mh. Human resources allocation based on number of employees per department are: Power = 5 employees, maintenance = 12 employees, human resources = 8 employees, accounting = 10 employees, cutting = 20 employees, shaping = 14 employees, painting = 16 employees, and packaging = 10 employees. Accounting allocation based on number of purchase orders per department are: Power = 20 purchase orders, maintenance = 35 purchase orders, human resources = 120 purchase orders, accounting = 25 purchase orders, cutting = 525 purchase orders, shaping = 400 purchase orders, painting = 725 purchase orders, and packaging = 200 purchase orders. = =

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts