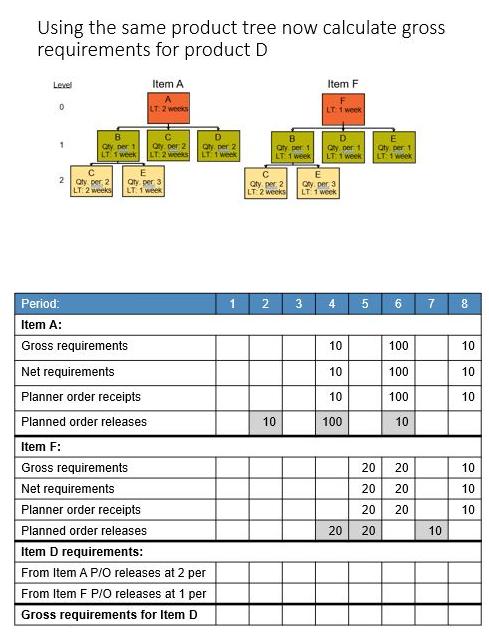

Question: Using the same product tree now calculate gross requirements for product D Level 0 2 8 City per 1 LT 1 week C Qty

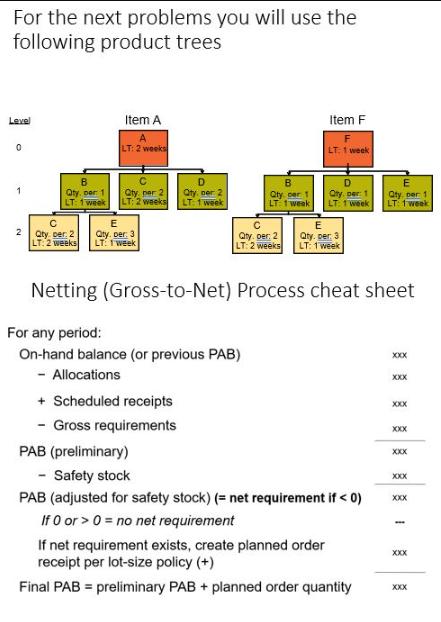

Using the same product tree now calculate gross requirements for product D Level 0 2 8 City per 1 LT 1 week C Qty per 2 LT: 2 weeks Period: Item A: Gross requirements Net requirements Planner order receipts Planned order releases Item A A LT: 2 weeks E aty per 3 LT 1 week Item F: Gross requirements Net requirements Planner order receipts Planned order releases Qty per: 2 LT. 2 weeks D Qty, per 2 LT. 1 week Item D requirements: From Item A P/O releases at 2 per From Item F P/O releases at 1 per Gross requirements for Item D B Qty per 1 LT 1 week Qty per 2 LT 2 weeks 1 2 10 Item F F LT 1 week 3 D GHI C LT. 1 week City, per 3 LT. 1 week 4 10 10 10 100 20 5 8888 20 20 E Qty per 1 LT 1 week 20 20 6 100 100 100 10 2282 20 20 20 7 10 8 10 10 10 10 10 10 For the next problems you will use the following product trees Level 0 1 2 Qty, per 1 LT: 1 week Qty per 2 LT. 2 weeks Item A A LT: 2 weeks C Qty per 2 LT: 2 weeks E Qty. Der: 3 LT: 1 week D Qty: ner 2 LT: 1 week + Scheduled receipts - Gross requirements Qty per 1 LT: 1 weak C Qty. Der; 2 LT: 2 weeks For any period: On-hand balance (or previous PAB) - Allocations Item F LT. 1 week D Qty, per: 1 LT: 1 week E Qty. per: 3 LT: 1 week Netting (Gross-to-Net) Process cheat sheet PAB (preliminary) - Safety stock PAB (adjusted for safety stock) (= net requirement if < 0) If 0 or > 0 = no net requirement E Qty, per 1 LT: 1 week If net requirement exists, create planned order receipt per lot-size policy (+) Final PAB = preliminary PAB+ planned order quantity XXX XXX XXX XXX XXX XXX XXX XXX XXX

Step by Step Solution

3.44 Rating (147 Votes )

There are 3 Steps involved in it

To calculate the gross requirements for product D we have to look at the product tree diagram and the information given for Item A and Item F Product ... View full answer

Get step-by-step solutions from verified subject matter experts