Question: Value stream map Using the below mentioned information to draw a current state value stream map (VSM): Moyos Inc based in Pietermaritzburg is a supplier

Value stream map

Using the below mentioned information to draw a current state value stream map (VSM):

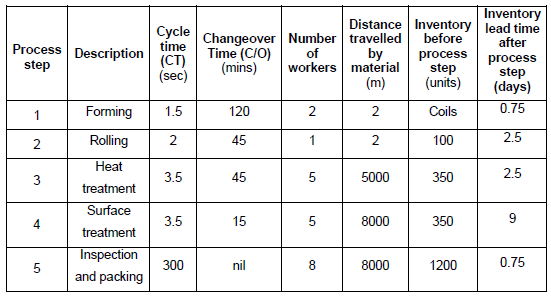

Moyos Inc based in Pietermaritzburg is a supplier of coils to MetalBox a manufacturer of hex bolts, based in Durban. The MetalBox Production Departments production schedule is based on orders received from its Sales Department according to orders from the Customers. MetalBox Production Department operates on annual forecast, monthly schedule and daily requirements to meet Customer orders. The supplier, Moyos Inc operates on a monthly forecast along with a weekly order. MetalBox holds 15-day buffer inventory of coils. The number of shifts per day at MetalBox is 2 and the working hours per shift is 9 hours including 30 minutes lunch break and two 15-minute tea breaks per shift. The demand for hex bolts is 8000 pieces per month, and the number of working days per month is 25. MetalBox currently keeps raw material inventory of 15 days in their warehouse, material moves from raw material store to finished items store through a number of processes that include cold forming, rolling, heat treatment, surface treatment, inspection and packing. The details regarding inventory, average cycle time, lead time, up-time, number of operators and distance travelled by material are against every machine are shown as below.

The production foreman noted some challenges with regards to overproduction during the forming process. In addition, the heat treatment and surface treatment of the bolts was are performed outside the company. The inspection and packing process was also characterised by poor organization of packing boxes and inspection tools.

\begin{tabular}{|c|c|c|c|c|c|c|c|} \hline Processstep & Description & Cycletime(CT)(sec) & ChangeoverTime(C/O)(mins) & Numberofworkers & Distancetravelledbymaterial(m) & Inventorybeforeprocessstep(units) & Inventoryleadtimeafterprocessstep(days) \\ \hline 1 & Forming & 1.5 & 120 & 2 & 2 & Coils & 0.75 \\ \hline 2 & Rolling & 2 & 45 & 1 & 2 & 100 & 2.5 \\ \hline 3 & Heattreatment & 3.5 & 45 & 5 & 5000 & 350 & 2.5 \\ \hline 4 & Surfacetreatment & 3.5 & 15 & 5 & 8000 & 350 & 9 \\ \hline 5 & Inspectionandpacking & 300 & nil & 8 & 8000 & 1200 & 0.75 \\ \hline \end{tabular} \begin{tabular}{|c|c|l|l|l|l|l|l|} \hline 6 & Shipmenttocustomer & & & & & 100 & \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts