Question: Vs: 1 2 V: 1 2 3 Currently, all manufacturing is done in the company's own plants located in the Cleveland area in the US

Vs:

V:

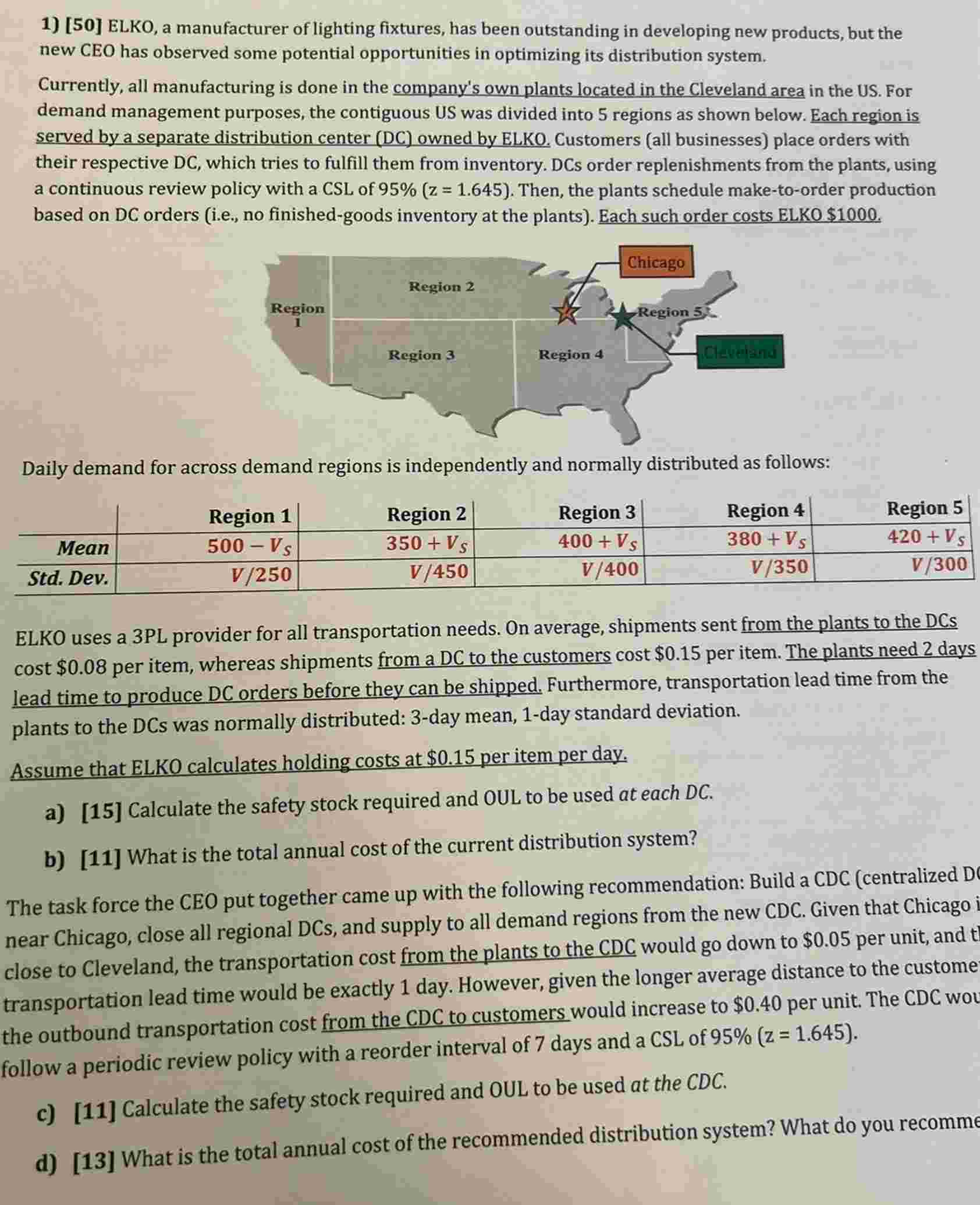

Currently, all manufacturing is done in the company's own plants located in the Cleveland area in the US For

demand management purposes, the contiguous US was divided into regions as shown below. Each region is

served by a separate distribution center DC owned by ELKO. Customers all businesses place orders with

their respective DC which tries to fulfill them from inventory. DCs order replenishments from the plants, using

a continuous review policy with a CSL of z Then, the plants schedule maketoorder production

based on DC orders ie no finishedgoods inventory at the plants Each such order costs ELKO $

Daily demand for across demand regions is independently and normally distributed as follows:

ELKO uses a PL provider for all transportation needs. On average, shipments sent from the plants to the DCs

cost $ per item, whereas shipments from a DC to the customers cost $ per item. The plants need days

lead time to produce DC orders before they can be shipped. Furthermore, transportation lead time from the

plants to the DCs was normally distributed: day mean, day standard deviation.

Assume that ELKO calculates holding costs at $ per item per day.

a Calculate the safety stock required and OUL to be used at each DC

b What is the total annual cost of the current distribution system?

The task force the CEO put together came up with the following recommendation: Build a CDC centralized D

near Chicago, close all regional DCs and supply to all demand regions from the new CDC Given that Chicago i

close to Cleveland, the transportation cost from the plants to the CDC would go down to $ per unit, and t

transportation lead time would be exactly day. However, given the longer average distance to the custome

the outbound transportation cost from the CDC to customers would increase to $ per unit. The CDC wou

follow a periodic review policy with a reorder interval of days and a CSL of z

c Calculate the safety stock required and OUL to be used at the CDC

d What is the total annual cost of the recommended distribution system? What do you recommend?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock