Question: War Eagle Golf Ltd . ( WEGL ) manufactures the Titanium Tiger ( T 2 ) driver, a $ 9 9 copycat of a far

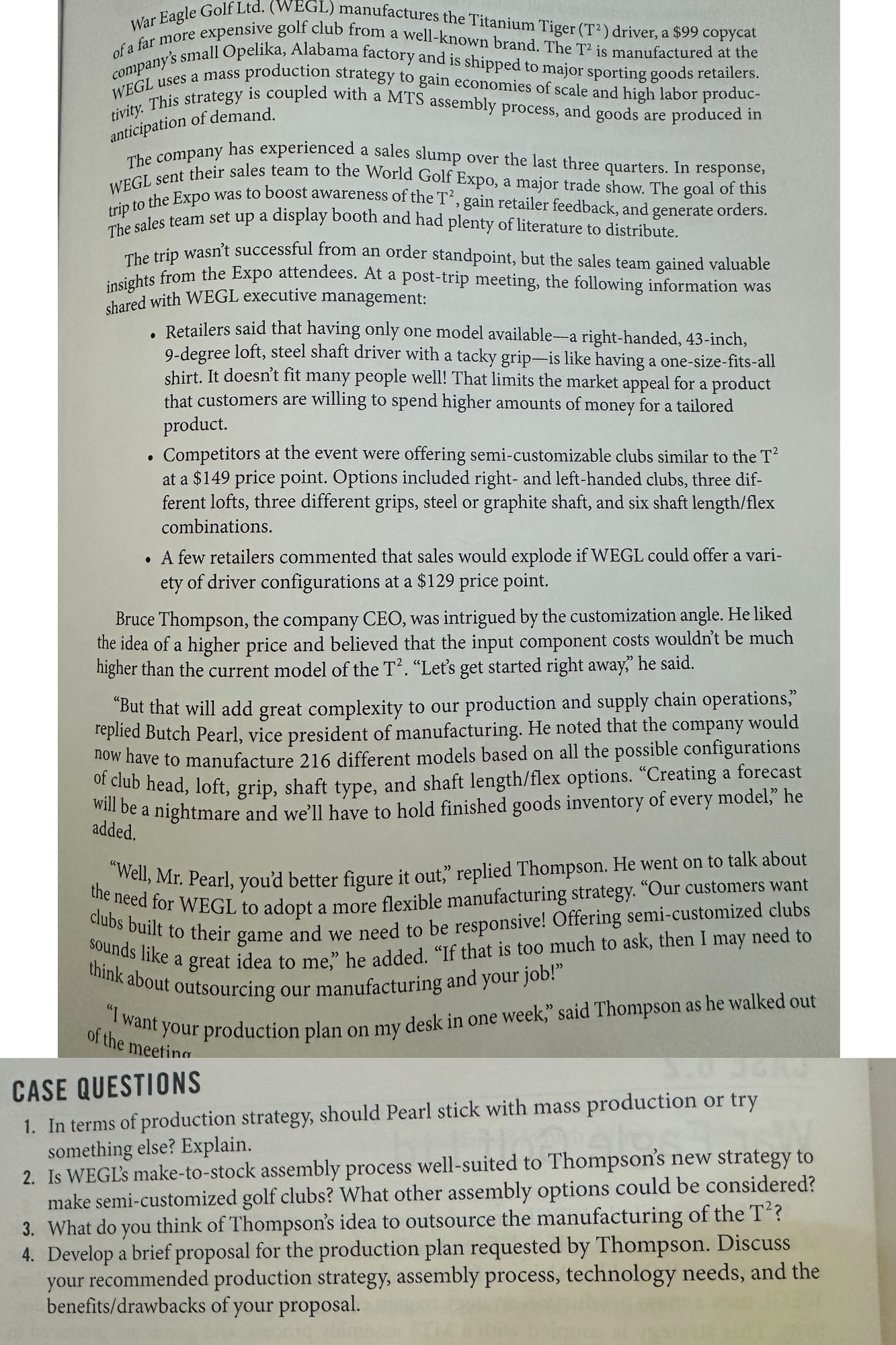

War Eagle Golf LtdWEGL manufactures the Titanium Tiger driver, a $ copycat

of a far more expensive golf club from a wellknown brand. The is manufactured at the

company's small Opelika, Alabama factory and is shipped to major sporting goods retailers.

WEGL uses a mass production strategy to gain economies of scale and high labor produc

tivity. This strategy is coupled with a MTS assembly process, and goods are produced in

anticipation of demand.

The company has experienced a sales slump over the last three quarters. In response,

WEGL sent their sales team to the World Golf Expo, a major trade show. The goal of this

trip to the Expo was to boost awareness of the gain retailer feedback, and generate orders.

The sales team set up a display booth and had plenty of literature to distribute.

The trip wasn't successful from an order standpoint, but the sales team gained valuable

insights from the Expo attendees. At a posttrip meeting, the following information was

shared with WEGL executive management:

Retailers said that having only one model availablea righthanded, inch,

degree loft, steel shaft driver with a tacky gripis like having a onesizefitsall

shirt. It doesn't fit many people well! That limits the market appeal for a product

that customers are willing to spend higher amounts of money for a tailored

product.

Competitors at the event were offering semicustomizable clubs similar to the

at a $ price point. Options included right and lefthanded clubs, three dif

ferent lofts, three different grips, steel or graphite shaft, and six shaft lengthflex

combinations.

A few retailers commented that sales would explode if WEGL could offer a vari

ety of driver configurations at a $ price point.

Bruce Thompson, the company CEO, was intrigued by the customization angle. He liked

the idea of a higher price and believed that the input component costs wouldn't be much

higher than the current model of the "Let's get started right away," he said.

"But that will add great complexity to our production and supply chain operations,"

replied Butch Pearl, vice president of manufacturing. He noted that the company would

now have to manufacture different models based on all the possible configurations

of club head, loft, grip, shaft type, and shaft lengthflex options. "Creating a forecast

will be a nightmare and we'll have to hold finished goods inventory of every model," he

added.

"Well, Mr Pearl, you'd better figure it out," replied Thompson. He went on to talk about

the need for WEGL to adopt a more flexible manufacturing strategy. "Our customers want

clubs built to their game and we need to be responsive! Offering semicustomized clubs

sounds like a great idea to me he added. If that is too much to ask, then I may need to

think about outsourcing our manufacturing and your job!"

"I want your production plan on my desk in one week," said Thompson as he walked out

of the meetins

CASE QUESTIONS

In terms of production strategy, should Pearl stick with mass production or try

something else? Explain.

Is WEGL's maketostock assembly process wellsuited to Thompson's new strategy to

make semicustomized golf clubs? What other assembly options could be considered?

What do you think of Thompson's idea to outsource the manufacturing of the

Develop a brief proposal for the production plan requested by Thompson. Discuss

your recommended production strategy, assembly process, technology needs, and the

benefitsdrawbacks of your proposal.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock