Question: WARING ! ! DONT USE AI TOOLS ! ! WARING ! ! DONT USE AI TOOLS ! ! WARING ! ! DONT USE AI TOOLS

WARING DONT USE AI TOOLS

WARING DONT USE AI TOOLS

WARING DONT USE AI TOOLS

WARING DONT USE AI TOOLS

WARING DONT USE AI TOOLS

SUBJECT OPERATIONS MANAGEMENT

Scenario:

You're the operations manager of a

manufacturing plant that produces three

products: A B and C Demand is increasing,

leading to capacity issues.

Data:

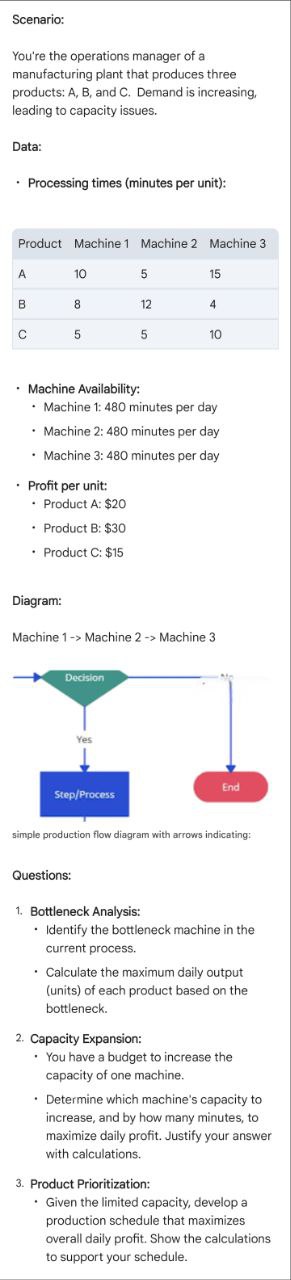

Processing times minutes per unit:

Machine Availability:

Machine : minutes per day

Machine : minutes per day

Machine : minutes per day

Profit per unit:

Product A: $

Product B: $

Product C: $

Diagram:

Machine Machine Machine

simple production flow diagram with arrows indicating:

Questions:

Bottleneck Analysis:

Identify the bottleneck machine in the

current process.

Calculate the maximum daily output

units of each product based on the

bottleneck.

Capacity Expansion:

You have a budget to increase the

capacity of one machine.

Determine which machine's capacity to

increase, and by how many minutes, to

maximize daily profit. Justify your answer

with calculations.

Product Prioritization:

Given the limited capacity, develop a

production schedule that maximizes

overall daily profit. Show the calculations

to support your schedule.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock