Question: We drilled a 1 2 . 2 5 ' ' vertical hole section down to 1 0 , 0 0 0 f t . The

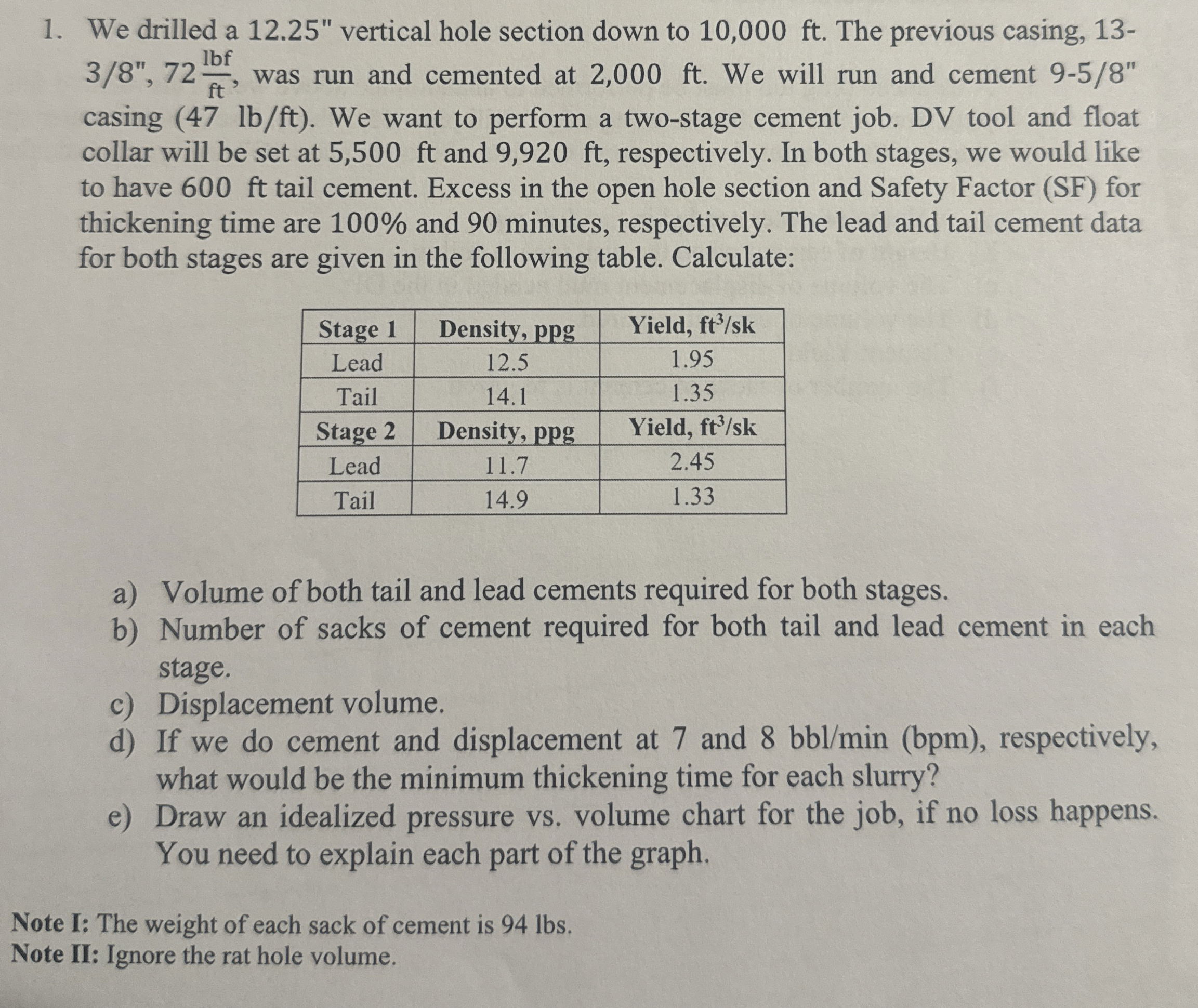

We drilled a vertical hole section down to The previous casing,

was run and cemented at We will run and cement

casing We want to perform a twostage cement job. DV tool and float

collar will be set at and respectively. In both stages, we would like

to have ft tail cement. Excess in the open hole section and Safety Factor SF for

thickening time are and minutes, respectively. The lead and tail cement data

for both stages are given in the following table. Calculate:

a Volume of both tail and lead cements required for both stages.

b Number of sacks of cement required for both tail and lead cement in each

stage.

c Displacement volume.

d If we do cement and displacement at and respectively,

what would be the minimum thickening time for each slurry?

e Draw an idealized pressure vs volume chart for the job, if no loss happens.

You need to explain each part of the graph.

Note I: The weight of each sack of cement is lbs

Note II: Ignore the rat hole volume.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock