Question: We have a process shown in the right figure. ( M 1 - M 4 are names for four machines. The numbers are activity times

We have a process shown in the right figure. MM are names for four

machines. The numbers are activity times in minutes Consider a schedule:

schedule a job on M every minutes, starting at time ; schedule a job on M

every minutes starting at time Jobs finished on M go to M; jobs finished

on go to

Question point

Find the WIP on each machine and complete the table.

Keep three decimals if required.

M

A WIP units

M

A WIP units

M

A WIP units

M

A WIP units

Total

A WIP unitsConsider the Chipotle example we discussed in the class. But this time, both Under the arrival schedule given in the previous question Week Exercise

Gantt Chart, calculate the following runtime parameters:

Demand Rate:

A unitshour

Flow Rate:

A unitshour

Actual Cycle Time:

A secunit

WIP for M:

A units

WIP for M:

A units

WIP for Buffer:

A units

WIP for M:

A units

Total WIP:

A units

Flow Time:

A We have a process shown in the right figure. MM are names for four

machines. The numbers are activity times in minutes Consider a schedule:

schedule a job on M every minutes, starting at time ; schedule a job on M

every minutes starting at time Jobs finished on M go to M; jobs finished

on M go to M

Question point

Find the WIP on each machine and complete the table.

Keep three decimals if required.

A WIP units

M

M

Total

A WIP units

A WIP units

A WIP units The flow time average throughput time

minutes

Hint: Every minutes, job come to the process job to M jobs to M To

get the average TPT you need to calculate the throughput time for each of the

three jobs and then do an average. Keep two decimals.

A

Question point

The flow rate under the given schedule is

unitshour

A

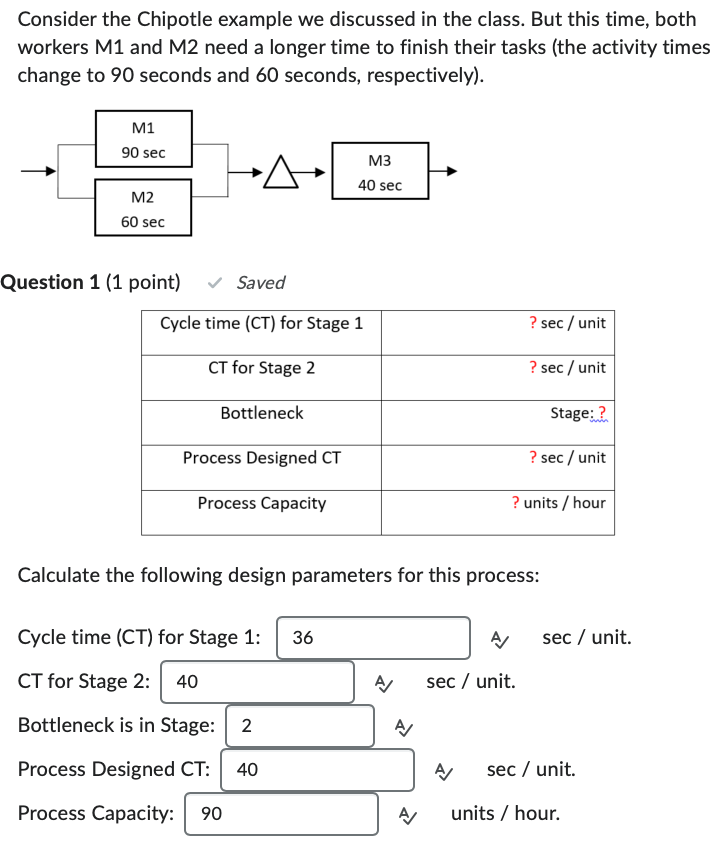

workers M and M need a longer time to finish their tasks the activity times

change to seconds and seconds, respectively

Question point

Calculate the following design parameters for this process:

Cycle time CT for Stage :

A unit.

CT for Stage :

A sec unit.

Bottleneck is in Stage:

A

Process Designed CT:

A sec unit.

Process Capacity:

A units hour.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock