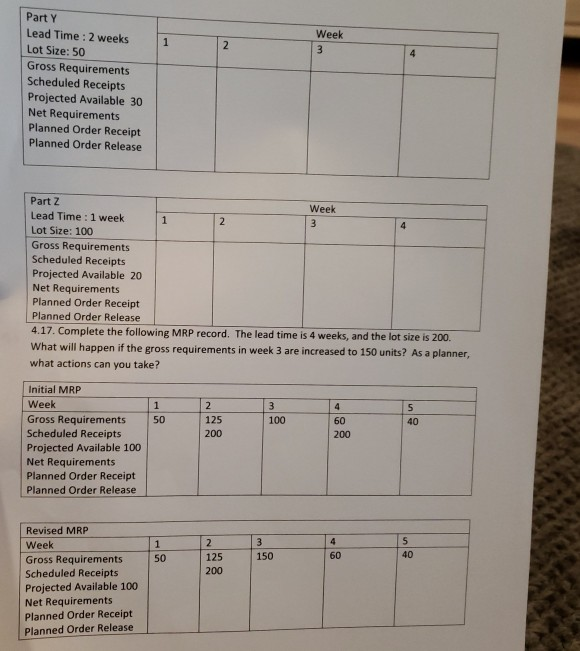

Question: Week Part Y Lead Time: 2 weeks Lot Size: 50 Gross Requirements Scheduled Receipts Projected Available 30 Net Requirements Planned Order Receipt Planned Order Release

Week Part Y Lead Time: 2 weeks Lot Size: 50 Gross Requirements Scheduled Receipts Projected Available 30 Net Requirements Planned Order Receipt Planned Order Release Part 2 Week Lead Time : 1 week Lot Size: 100 Gross Requirements Scheduled Receipts Projected Available 20 Net Requirements Planned Order Receipt Planned Order Release 4.17. Complete the following MRP record. The lead time is 4 weeks, and the lot size is 200. What will happen if the gross requirements in week 3 are increased to 150 units? As a planner, what actions can you take? 2 3 14 50 125 100 200 200 Initial MRP Week Gross Requirements Scheduled Receipts Projected Available 100 Net Requirements Planned Order Receipt Planned Order Release 150 125 60 200 Revised MRP Week Gross Requirements Scheduled Receipts Projected Available 100 Net Requirements Planned Order Receipt Planned Order Release Week Part Y Lead Time: 2 weeks Lot Size: 50 Gross Requirements Scheduled Receipts Projected Available 30 Net Requirements Planned Order Receipt Planned Order Release Part 2 Week Lead Time : 1 week Lot Size: 100 Gross Requirements Scheduled Receipts Projected Available 20 Net Requirements Planned Order Receipt Planned Order Release 4.17. Complete the following MRP record. The lead time is 4 weeks, and the lot size is 200. What will happen if the gross requirements in week 3 are increased to 150 units? As a planner, what actions can you take? 2 3 14 50 125 100 200 200 Initial MRP Week Gross Requirements Scheduled Receipts Projected Available 100 Net Requirements Planned Order Receipt Planned Order Release 150 125 60 200 Revised MRP Week Gross Requirements Scheduled Receipts Projected Available 100 Net Requirements Planned Order Receipt Planned Order Release

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts