Question: Welding simulation Assignment - II Casting and Welding ( S 1 - 2 4 _ ETZC 2 3 5 / PEZC 2 3 6 )

Welding simulation Assignment II

Casting and Welding SETZCPEZC

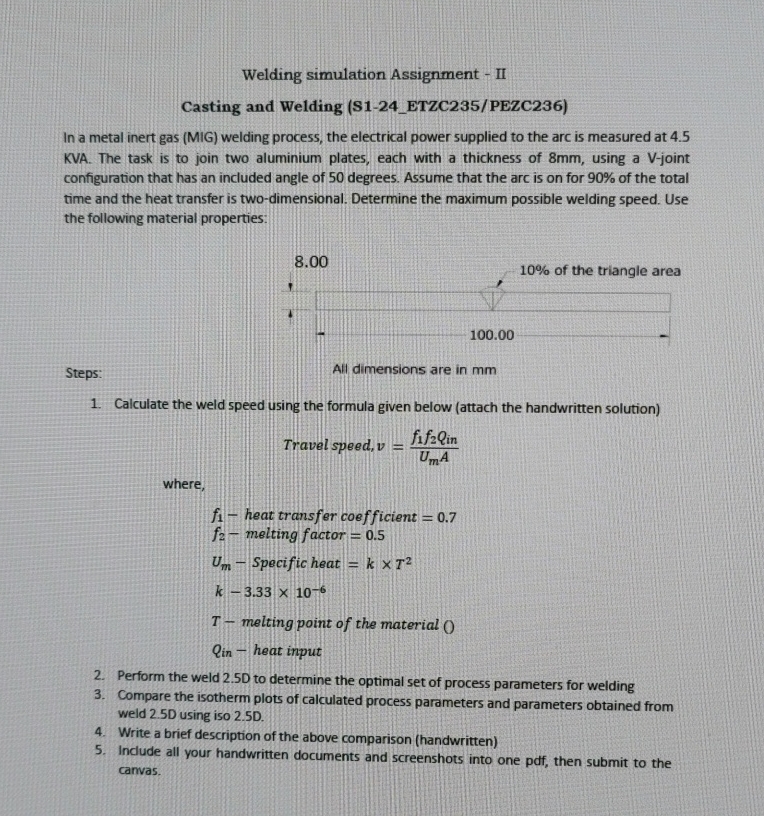

In a metal inert gas MIG welding process, the electrical power supplied to the arc is measured at

KVA. The task is to join two aluminium plates, each with a thickness of mm using a Vjoint

configuration that has an included angle of degrees. Assume that the arc is on for of the total

time and the heat transfer is twodimensional. Determine the maximum possible welding speed. Use

the following material properties:

Steps:

Calculate the weld speed using the formula given below attach the handwritten solution

Travel speed,

where,

heat trans fer coefficient

melting factor

Specific heat

melting point the material

heat input

Perform the weld D to determine the optimal set of process parameters for welding

Compare the isotherm plots of calculated process parameters and parameters obtained from

weld D using iso

Write a brief description of the above comparison handwritten

Include all your handwritten documents and screenshots into one pdf then submit to the

canvas.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock