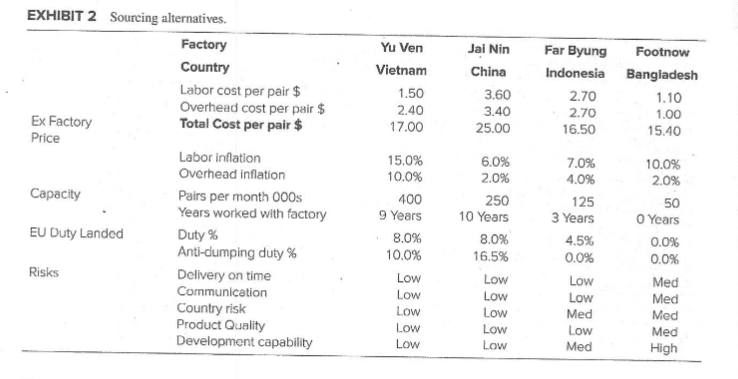

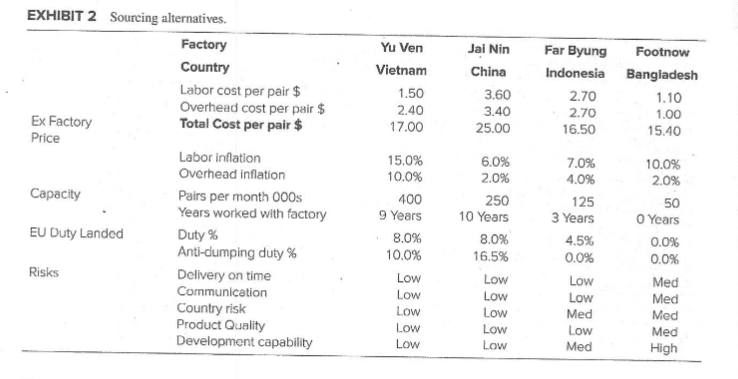

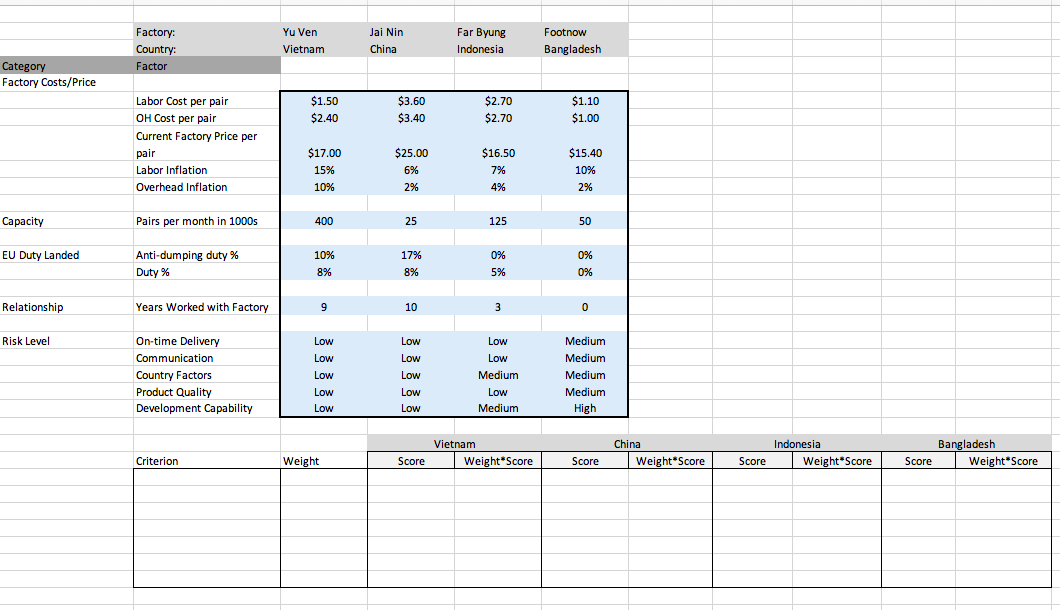

Question: What are 7 most important criteria for selection process, and appropriate weight for each criteria? EXHIBIT 2 Sourcing alternatives. Factory Country Labor cost per pair

What are 7 most important criteria for selection process, and appropriate weight for each criteria?

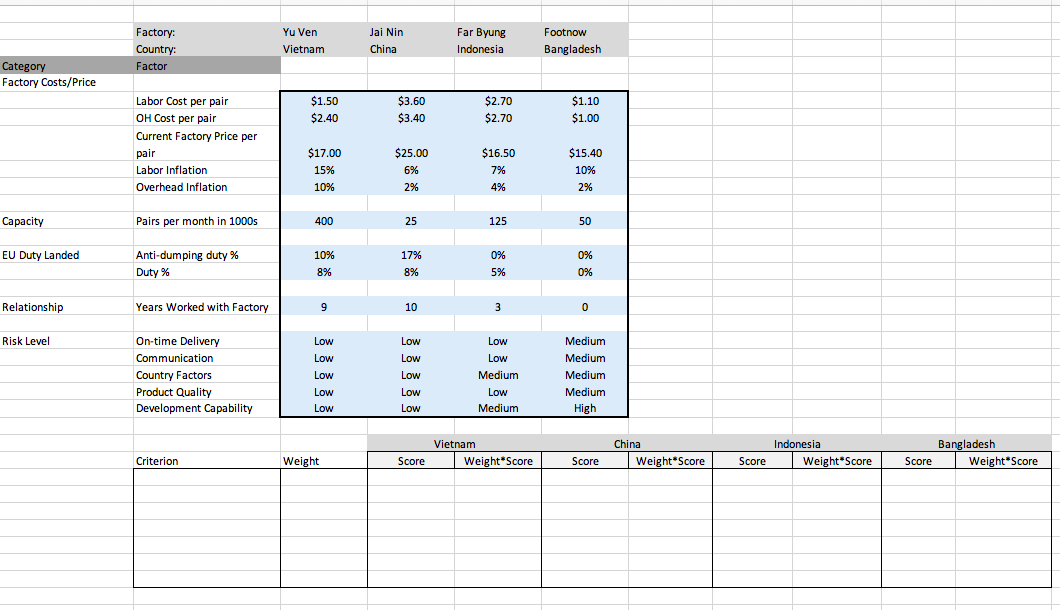

EXHIBIT 2 Sourcing alternatives. Factory Country Labor cost per pair $ Overhead cost per pair $ Total Cost per pair $ Yu Ven Vietnam 1.50 2.40 17.00 Jai Nin China 3.60 3.40 25.00 Far Byung Indonesia 2.70 2.70 16.50 Footnow Bangladesh 1.10 1.00 15.40 Ex Factory Price 10.0% 2.0% Capacity 15.0% 10.0% 400 9 Years 8.0% EU Duty Landed Labor inflation Overhead inflation Pairs per month 000s Years worked with factory Duty % Anti-dumping duty % Delivery on time Communication Country risk Product Quality Development capability 10.0% 6.0% 2.0% 250 10 Years 8.0% 16.5% Low Low Low Low Low 7.0% 4.0% 125 3 Years 4.5% 0.0% Low Low Med Low Med Risks Low O Years 0.0% 0.0% Med Med Med Med High Low Low Low Low Operations at Altimus Brands in London (UK), received the latest monthly report and, as he feared, costs of pur- chases had increased again. He knew that by the end of the month he would have to present recommendations to the board. He convened a meeting with his team of buyers to prepare the recommendations focusing on Rocky Mountain, their top-selling brand. ALTIMUS BRANDS Altimus is a family-owned business with a global presence in the footwear sector. The company owns a portfolio of seven premium footwear brands, marketed in some 120 countries and in 2010 reached 1.3 bn in sales. Altimus operates about 230 retail outlets worldwide, but it also sold its products through other channels. Although the company name is rarely recognized by people outside the industry, its brands were well known around the world and considered the company's most valuable assets. To maintain and develop the value of its brands, the company relies on four core competencies: innovation, design, quality and supply chain management. For many years manufacturing has not been central to the busi- ness; in fact they were one of the pioneers in sourcing from Asia, where they had been operating since the 1960s. It was precisely for this reason that Enzo believed the selection, management and development of suppli- ers were key success factors. THE GLOBAL FOOTWEAR INDUSTRY Impact of the Economic Situation The footwear market had been badly hit by the reces sion and many retailers and producers had gone bank- rupt, with the surviving players fighting for market share. Although the management team at Altimus expected that consumer confidence would start to improve, weaker wage growth and the possibility of future job cuts, particularly in Europe, could lead to consumers remaining cautious for longer. The global market for premium footwear brands was dominated by Europe and North America, although devel- Tamrowuar sector Traditionally there were two collections per year (Spring- Summer and Autumn-Winter) and hundreds of new mod- els were designed and produced every season. However there was evidence that competition was shift- ing to a "Fast fashion model led by companies like Zara and H&M, which introduced more collections per year. Some companies were talking about 13 collections per year; one every four weeks. Technologies were also changing constantly, both in terms of materials and pro- duction processes. "This continuous change makes it very difficult to manage the supply chain said Enzo. Corporate Social Responsibility (CSR) and in particu- lar ethical issues such as fair trade, child labor, use of sweat shops were a growing concern for companies in the footwear and clothing sector. Companies with strong brands such as Adidas, Burberry, Gap and Nike had found themselves as central protagonists in major scan- dals, usually the result of ethical violations by director indirect suppliers. In recent years, global initiatives such as the Global Compact, promoted by the UN, and the Ethical Trading Initiative (ETI) were launched to promote ethical and responsible business practices. ALTIMUS SUPPLY CHAIN Supply Chain Strategy and Structure Altimus, like many other companies in this sector, acted as a supply chain integrator. It managed the suppliers, who manufactured the shoes; it coordinated the logis- tics through third party logistics providers (3PLs); and it controlled the distribution channels (see Exhibit 1). Enzo believed this approach allowed flexibility in terms of pro- duction capacity and required no investment in produc- tion assets. However, he also recognised a major limitation was that the control of manufacturing costs remained outside the boundaries of the organization. The only levers they had to reduce production costs were price negotiations, product specification and sup plier switching. Altimus had focused its supplier development efforts Factory: Country: Factor Yu Ven Vietnam Jai Nin China Far Byung Indonesia Footnow Bangladesh Category Factory Costs/Price $1.50 $2.40 $3.60 $3.40 $2.70 $2.70 $1.10 $1.00 Labor Cost per pair OH Cost per pair Current Factory Price per pair Labor Inflation Overhead Inflation $16.50 $15.40 $17.00 15% 10% $25.00 6% 2% 7% 10% 4% 2% Capacity Pairs per month in 1000s 400 EU Duty Landed 10% 17% Anti-dumping duty % Duty % 8% Relationship Years Worked with Factory Risk Level On-time Delivery Communication Country Factors Product Quality Development Capability Low Low Low Low Low Low Low Low Low Low Low Low Medium Low Medium Medium Medium Medium Medium High Vietnam Weight *Score | China Weight*Score Indonesia Weight*Score | Bangladesh Weight "Score Criterion Weight Score Score S core Score