Question: What are the major problems being faced by Eastern Gear? What action should Rhodes take to solve his problems? How can this case be related

- What are the major problems being faced by Eastern Gear?

- What action should Rhodes take to solve his problems?

- How can this case be related to operations strategy and process design concepts?

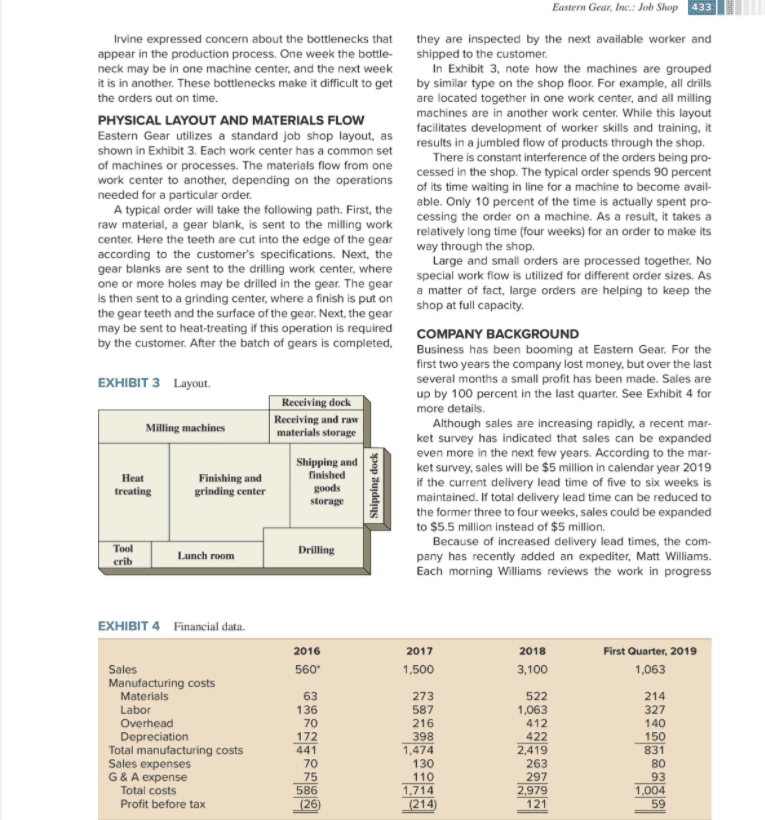

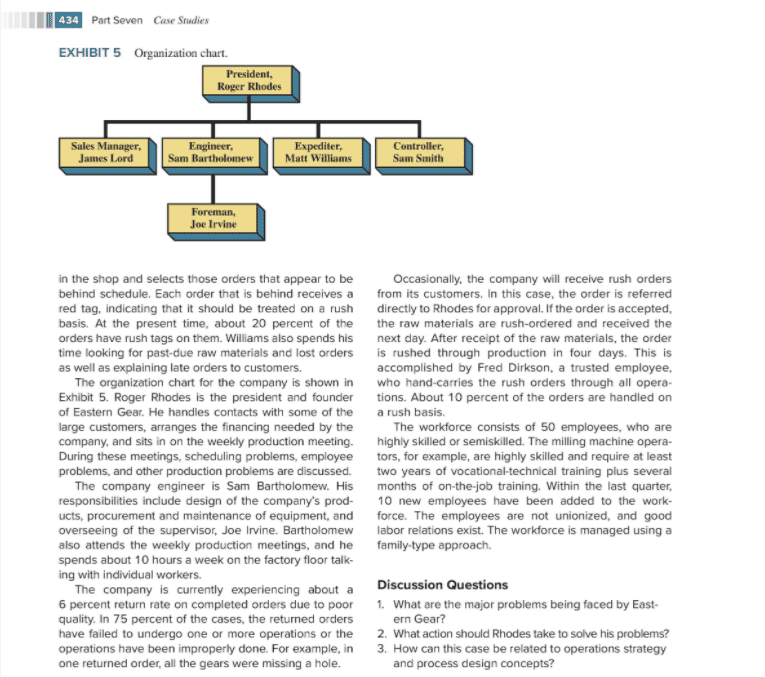

Case Study Eastern Gear, Inc.: Job Shop Eastern Gear, Inc., in Philadelphia, Pennsylvania, is a ORDER ENTRY manufacturer of custom-made gears ranging in weight When a customer wishes to order a gear, the order is from a few ounces to over 50 pounds. The gears are taken by James Lord, sales manager and marketing vice made of different metals, depending on the customer's president. The customer specifies the type of gear desired requirements. Over the past year, 40 different types of by submitting a blueprint or sketch. The quantity of gears steel and brass alloys have been used as raw materials. required and the type of material are also specified by See Exhibit 1 for details. the customer. On occasion, the customer's engineer will Eastern Gear sells its products primarily to engineer- call up after the order has been placed and request a ing research and development laboratories or very change in the design. In these cases, it may be necessary small manufacturers. As a result, the number of gears to stop production and wait for new raw materials or for in most orders is small; rarely is exactly the same gear the design to be clarified. The customer's prints submitted ordered more than once. The distribution of order sizes with the order do not always contain the tolerances or fin- for March 2019 is shown in Exhibit 2. ishes required during machining. As a result, the customer Recently, the president of Eastern Gear decided is contacted directly when the information is needed. to accept a few larger orders for 100 gears or more. After the order is received, one electronic copy is Although lower prices were accepted on these orders, sent to the production supervisor, Joe Irvine, and the they helped pay the overhead. It was found that the second copy is sent to Sam Smith, the controller. Upon large orders caused many of the small orders to wait for receipt of the customer's order, Smith places a purchase a long time before being processed. As a result, some order for the raw materials required. These materials deliveries of small orders were late. often take from one to two weeks to arrive, depending on the supplier and the type of material ordered. After receiving the customer order, the supervi- sor reviews the order and places it on file until the raw material arrives. The customer order is then routed through the shop along with the materials. In the past. the production process for most gears has taken about two weeks after receipt of raw materials. Recently this production time has increased to four weeks. EXHIBIT 2 Sales, March 2019. hanoiphotography/123RF EXHIBIT 1 Raw materials. Type of Material Order Size 1 2 3 4 5 8 10 15 20 25 30 40 50 100 200 400 700 1,000 2019 Usage $(000) $ 36 10 15 43 110 18 32 75 40 60 30 53 $522 Number of Orders 80 53 69 32 82 47 64 22 42 27 18 22 10 4 2 1 2 1 578 Total $ Value of Orders $ 3,200 4,250 8,163 4,800 16,392 15,987 26,871 13,172 31,555 23,682 21,600 32,000 18,693 12,500 14,068 9,652 35,600 20,000 $312,185 IO TIMU J K All Others Total Eastern Gear, Inc.: Job Shop 433 Irvine expressed concern about the bottlenecks that they are inspected by the next available worker and appear in the production process. One week the bottle shipped to the customer. neck may be in one machine center, and the next week In Exhibit 3, note how the machines are grouped it is in another. These bottlenecks make it difficult to get by similar type on the shop floor. For example, all drills the orders out on time. are located together in one work center, and all milling PHYSICAL LAYOUT AND MATERIALS FLOW machines are in another work center. While this layout Eastern Gear utilizes a standard job shop layout, as facilitates development of worker skills and training, it shown in Exhibit 3. Each work center has a common set results in a jumbled flow of products through the shop. of machines or processes. The materials flow from one There is constant interference of the orders being pro- work center to another, depending on the operations cessed in the shop. The typical order spends 90 percent of its time waiting in line for a machine to become avail- needed for a particular order. A typical order will take the following path. First, the able. Only 10 percent of the time is actually spent pro- raw material, a gear blank, is sent to the milling work cessing the order on a machine. As a result, it takes a relatively long time (four weeks) for an order to make its center. Here the teeth are cut into the edge of the gear according to the customer's specifications. Next, the way through the shop. Large and small orders are processed together. No gear blanks are sent to the drilling work center, where special work flow is utilized for different order sizes. As one or more holes may be drilled in the gear. The gear is then sent to a grinding center, where a finish is put on a matter of fact, large orders are helping to keep the the gear teeth and the surface of the gear. Next, the gear shop at full capacity. may be sent to heat-treating if this operation is required COMPANY BACKGROUND by the customer. After the batch of gears is completed, Business has been booming at Eastern Gear. For the first two years the company lost money, but over the last EXHIBIT 3 Layout several months a small profit has been made. Sales are Receiving dock up by 100 percent in the last quarter. See Exhibit 4 for more details. Receiving and raw Milling machines Although sales are increasing rapidly, a recent mar- materials storage ket survey has indicated that sales can be expanded even more in the next few years. According to the mar- Shipping and ket survey, sales will be $5 million in calendar year 2019 Heat Finishing and finished if the current delivery lead time of five to six weeks is treating grinding center goods storage maintained. If total delivery lead time can be reduced to the former three to four weeks, sales could be expanded to $5.5 million instead of $5 million Tool Because of increased delivery lead times, the com- Lunchroom Drilling pany has recently added an expediter, Matt Williams. Each morning Williams reviews the work in progress Shipping dock crib EXHIBIT 4 Financial data. 2016 560 2017 1,500 First Quarter, 2019 1,063 63 136 Sales Manufacturing costs Materials Labor Overhead Depreciation Total manufacturing costs Sales expenses G & A expense Total costs Profit before tax 70 172 441 70 75 586 (26) 273 587 216 398 1,474 130 110 1.714 (214) 2018 3,100 522 1,063 412 422 2,419 263 297 2,979 121 214 327 140 150 831 80 93 1,004 59 434 Part Seven Case Studies EXHIBIT 5 Organization chart. President, Roger Rhodes Sales Manager, James Lord Engineer, Sam Bartholomew Expediter, Matt Williams Controller, Sam Smith Foreman, Joe Irvine in the shop and select those orders that appear to be Occasionally, the company will receive rush orders behind schedule. Each order that is behind receives a from its customers. In this case, the order is referred red tag, indicating that it should be treated on a rush directly to Rhodes for approval. If the order is accepted, basis. At the present time, about 20 percent of the the raw materials are rush-ordered and received the orders have rush tags on them. Williams also spends his next day. After receipt of the raw materials, the order time looking for past-due raw materials and lost orders is rushed through production in four days. This is as well as explaining late orders to customers. accomplished by Fred Dirkson, a trusted employee, The organization chart for the company is shown in who hand-carries the rush orders through all opera- Exhibit 5. Roger Rhodes is the president and founder tions. About 10 percent of the orders are handled on of Eastern Gear. He handles contacts with some of the a rush basis. large customers, arranges the financing needed by the The workforce consists of 50 employees, who are company, and sits in on the weekly production meeting. highly skilled or semiskilled. The milling machine opera- During these meetings, scheduling problems, employee tors, for example, are highly skilled and require at least problems, and other production problems are discussed. two years of vocational-technical training plus several The company engineer is Sam Bartholomew. His months of on-the-job training. Within the last quarter, responsibilities include design of the company's prod- 10 new employees have been added to the work- ucts, procurement and maintenance of equipment, and force. The employees are not unionized, and good overseeing of the supervisor, Joe Irvine. Bartholomew labor relations exist. The workforce is managed using a also attends the weekly production meetings, and he family-type approach. spends about 10 hours a week on the factory floor talk- ing with individual workers. The company is currently experiencing about a Discussion Questions 6 percent return rate on completed orders due to poor 1. What are the major problems being faced by East- quality. In 75 percent of the cases, the returned orders ern Gear? have failed to undergo one or more operations or the 2. What action should Rhodes take to solve his problems? operations have been improperly done. For example, in 3. How can this case be related to operations strategy one returned order, all the gears were missing a hole. and process design concepts

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock