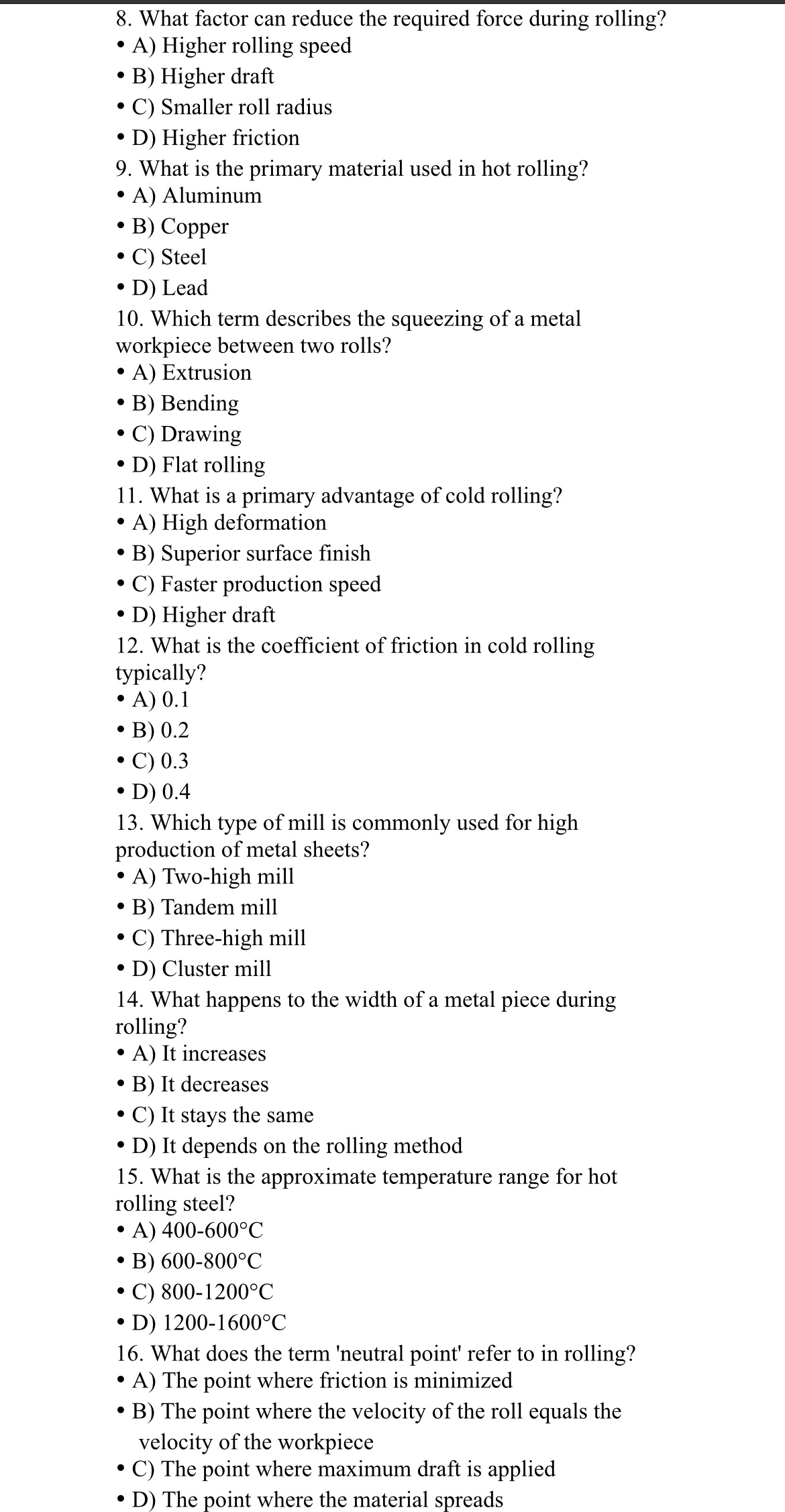

Question: What factor can reduce the required force during rolling? A ) Higher rolling speed B ) Higher draft C ) Smaller roll radius D )

What factor can reduce the required force during rolling?

A Higher rolling speed

B Higher draft

C Smaller roll radius

D Higher friction

What is the primary material used in hot rolling?

A Aluminum

B Copper

C Steel

D Lead

Which term describes the squeezing of a metal

workpiece between two rolls?

A Extrusion

B Bending

C Drawing

D Flat rolling

What is a primary advantage of cold rolling?

A High deformation

B Superior surface finish

C Faster production speed

D Higher draft

What is the coefficient of friction in cold rolling

typically?

A

B

C

D

Which type of mill is commonly used for high

production of metal sheets?

A Twohigh mill

B Tandem mill

C Threehigh mill

D Cluster mill

What happens to the width of a metal piece during

rolling?

A It increases

B It decreases

C It stays the same

D It depends on the rolling method

What is the approximate temperature range for hot

rolling steel?

A

B

C

D

What does the term 'neutral point' refer to in rolling?

A The point where friction is minimized

B The point where the velocity of the roll equals the

velocity of the workpiece

C The point where maximum draft is applied

D The point where the material spreads

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock