Question: What factors (e .g.stakeholders, timelines, and underlying issues) should be considered in developing a recommendation? Figure 16.18 CASE STUDY 16.1 Accent Oak Furniture Company Accent

What factors (e .g.stakeholders, timelines, and underlying issues) should be considered in developing a recommendation?

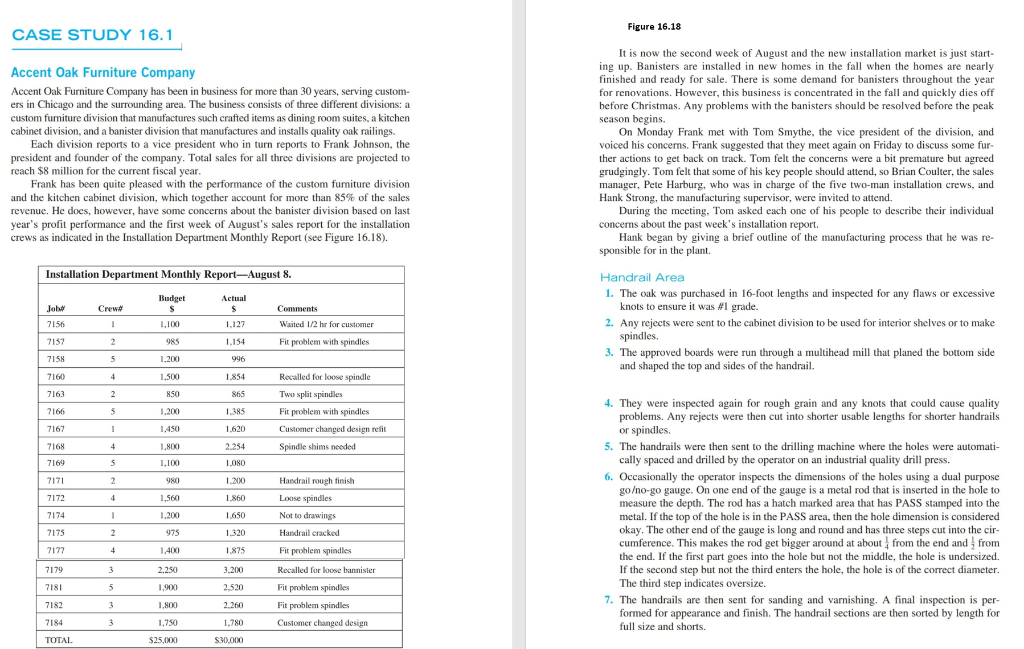

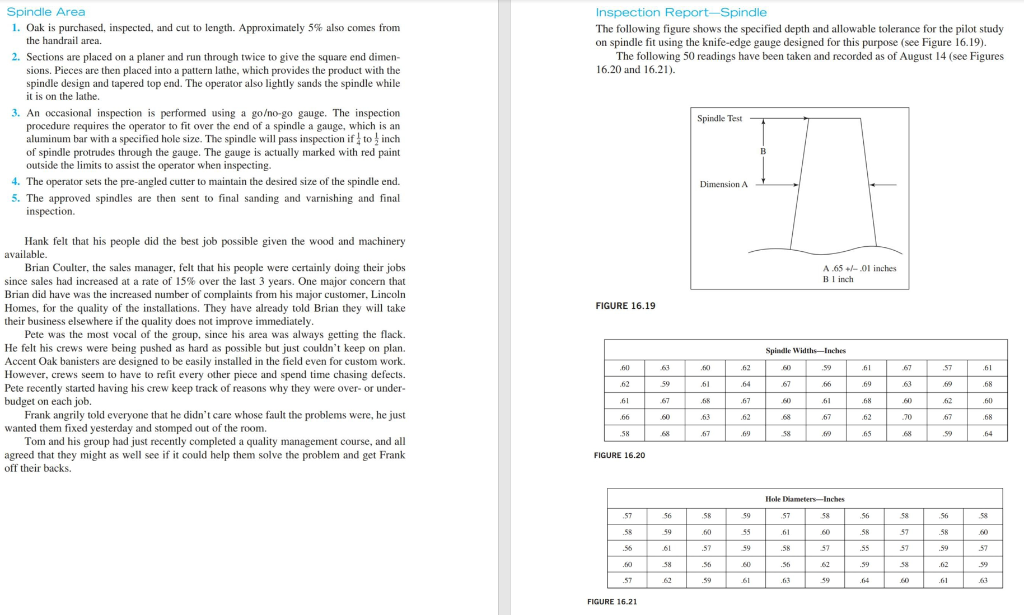

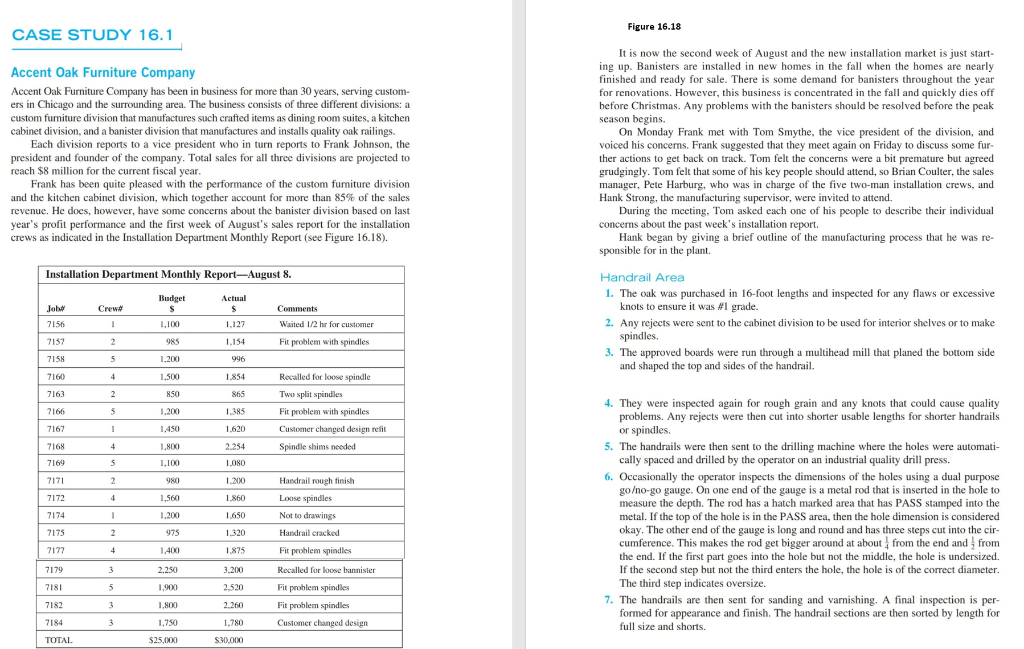

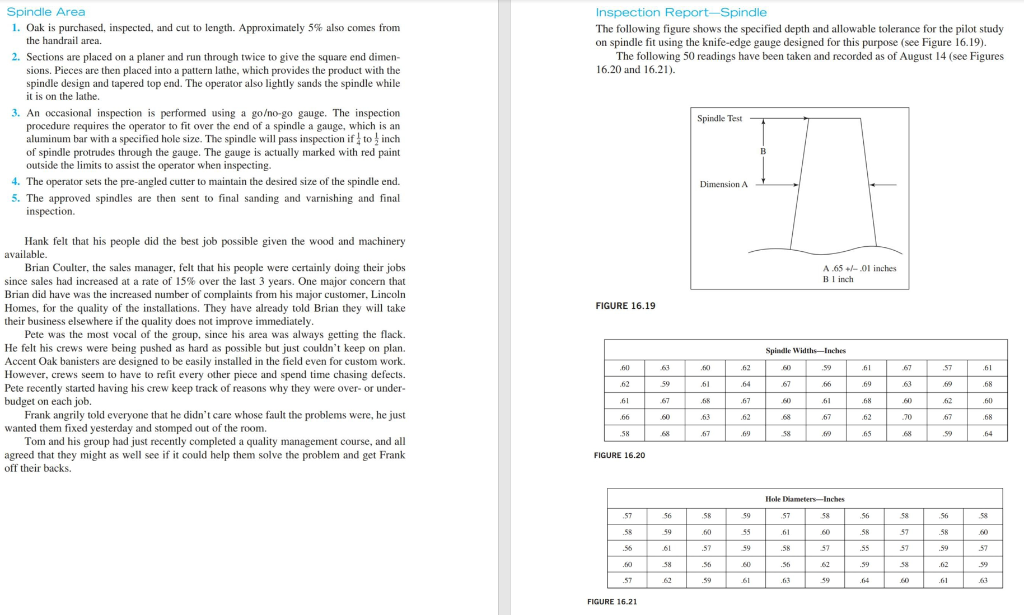

Figure 16.18 CASE STUDY 16.1 Accent Oak Furniture Company Accent Oak Furniture Company has been in business for more than 30 years, serving custom- ers in Chicago and the surrounding area. The business consists of three different divisions: a custom fumiture division that manufactures such crafted items as dining room suites, a kitchen cabinet division, and a banister division that manufactures and installs quality oak railings. Each division reports to a vice president who in turn reports to Frank Johnson, the president and founder of the company. Total sales for all three divisions are projected to reach $8 million for the current fiscal year. Frank has been quite pleased with the performance of the custom furniture division and the kitchen cabinet division, which together account for more than 85% of the sales revenue. He does, however, have some concerns about the banister division based on last year's profit performance and the first week of August's sales report for the installation crews as indicated in the Installation Department Monthly Report (see Figure 16.18). It is now the second week of August and the new installation market is just start- ing up. Banisters are installed in new homes in the fall when the homes are nearly finished and ready for sale. There is some demand for banisters throughout the year for renovations. However, this business is concentrated in the fall and quickly dies off before Christmas. Any problems with the banisters should be resolved before the peak season begins. On Monday Frank met with Tom Smythe, the vice president of the division, and voiced his concerns. Frank suggested that they meet again on Friday to discuss some fur- ther actions to get back on track. Tom felt the concerns were a bit premature but agreed grudgingly. Tom felt that some of his key people should attend, so Brian Coulter, the sales manager, Pete Harburg, who was in charge of the five two-man installation crews, and Hank Strong, the manufacturing supervisor, were invited to attend. During the meeting, Tom asked each one of his people to describe their individual concerns about the past week's installation report. Hank began by giving a brief outline of the manufacturing process that he was re- sponsible for in the plant Installation Department Monthly Report-August 8. Job Crew Budget S 1.100 Actual $ 7156 1 1.127 Waited 1/2 hr for customer Handrail Area 1. The oak was purchased in 16-foot lengths and inspected for any flaws or excessive knots to ensure it was #1 grade. 2. Any rejects were sent to the cabinet division to be used for interior shelves or to make spindles. 3. The approved boards were run through a multihead mill that planed the bottom side and shaped the top and sides of the handrail. 7157 985 1.154 Fit problem with spindles 7158 5 1,200 996 7160 4 1.500 1.854 7163 2 2 850 865 7166 5 1.200 1,385 Recalled for loose spindle Two split spindles Fit problem with spindles Customer changed design refit Spindle shims needed 7167 1 1.450 1.620 7168 4 1,800 2.254 7169 5 1.100 1.080 7171 2 980 1.200 7172 4 1,560 1.860 7174 1 1.200 1.650 4. They were inspected again for rough grain and any knots that could cause quality problems. Any rejects were then cut into shorter usable lengths for shorter handrails or spindles, 5. The handrails were then sent to the drilling machine where the holes were automati- cally spaced and drilled by the operator on an industrial quality drill press. 6. Occasionally the operator inspects the dimensions of the holes using a dual purpose goo-go gauge. On one end of the gauge is a metal rod that is inserted in the hole to measure the depth. The rod has a hatch marked area that has PASS stamped into the metal. If the top of the hole is in the PASS area, then the hole dimension is considered okay. The other end of the gauge is long and round and has three steps cut into the cir- cumference. This makes the rod get bigger around at about from the end and from the end. If the first part goes into the hole but not the middle, the hole is undersized. If the second step but not the third enters the hole, the hole is of the correct diameter. The third step indicates oversize. 7. The handrails are then sent for sanding and varnishing. A final inspection is per- formed for appearance and finish. The handrail sections are then sorted by length for full size and shorts. 7175 2 975 1.320 7177 4 1.400 1.875 Handrail rough finish Loose spindles Not to drawings Handrail cracked Fit problem spindles Recalled for loose Lannister Fit problem spindles Fit problem spindles Customer changed design 7179 3 2.250 1,900 3.200 2.520 7181 5 7182 3 1.800 2.260 1.780 7184 3 1.750 TOTAL $25,000 530.000 Inspection Report-Spindle The following figure shows the specified depth and allowable tolerance for the pilot study on spindle fit using the knife-edge gauge designed for this purpose (see Figure 16.19). The following 50 readings have been taken and recorded as of August 14 (see Figures 16.20 and 16.21). Spindle Area 1. Oak is purchased, inspected, and cut to length. Approximately 5% also comes from the handrail area. 2. Sections are placed on a planer and run through twice to give the square end dimen- sions. Pieces are then placed into a pattern lathe, which provides the product with the spindle design and tapered top end. The operator also lightly sands the spindle while it is on the lathe. 3. An occasional inspection is performed using a goo-go gauge. The inspection procedure requires the operator to fit over the end of a spindle a gauge, which is an aluminum bar with a specified hole size. The spindle will pass inspection ifto inch of spindle protrudes through the gauge. The gauge is actually marked with red paint outside the limits to assist the operator when inspecting 4. The operator sets the pre-angled cutter to maintain the desired size of the spindle end. 5. The approved spindles are then sent to final sanding and varnishing and final inspection Spindle Test B Dimension A A.65 +/-01 inches B 1 inch FIGURE 16.19 Hank felt that his people did the best job possible given the wood and machinery available. Brian Coulter, the sales manager, felt that his people were certainly doing their jobs since sales had increased at a rate of 15% over the last 3 years. One major concern that Brian did have was the increased number of complaints from his major customer, Lincoln Homes, for the quality of the installations. They have already told Brian they will take their business elsewhere if the quality does not improve immediately. Pete was the most vocal of the group, since his area was always getting the flack He felt his crews were being pushed as hard as possible but just couldn't keep on plan. Accent Oak banisters are designed to be easily installed in the field even for custom work. However, crews seem to have to refit every other piece and spend time chasing defects. Pete recently started having his crew keep track of reasons why they were over- or under- budget on each job. Frank angrily told everyone that he didn't care whose fault the problems were, he just wanted them fixed yesterday and stomped out of the room. Tom and his group had just recently completed a quality management course, and all agreed that they might as well see if it could help them solve the problem and get Frank off their backs. Spindle Widths-Inches .60 63 .60 .62 60 .61 .67 .57 .61 .62 59 .61 .64 67 16 .69 .619 68 .61 67 .68 .67 60 .68 .62 .60 66 163 .62 .67 62 70 67 .68 .58 .69 58 . .65 59 .64 FIGURE 16.20 Hole Diameters-Inches .57 56 58 59 56 58 57 .58 59 .60 57 .61 58 55 .58 .58 60 57 61 .57 59 .55 57 .59 57 38 .56 60 .56 62 .39 38 .62 .57 62 .59 61 .63 39 60 .61 FIGURE 16.21 Figure 16.18 CASE STUDY 16.1 Accent Oak Furniture Company Accent Oak Furniture Company has been in business for more than 30 years, serving custom- ers in Chicago and the surrounding area. The business consists of three different divisions: a custom fumiture division that manufactures such crafted items as dining room suites, a kitchen cabinet division, and a banister division that manufactures and installs quality oak railings. Each division reports to a vice president who in turn reports to Frank Johnson, the president and founder of the company. Total sales for all three divisions are projected to reach $8 million for the current fiscal year. Frank has been quite pleased with the performance of the custom furniture division and the kitchen cabinet division, which together account for more than 85% of the sales revenue. He does, however, have some concerns about the banister division based on last year's profit performance and the first week of August's sales report for the installation crews as indicated in the Installation Department Monthly Report (see Figure 16.18). It is now the second week of August and the new installation market is just start- ing up. Banisters are installed in new homes in the fall when the homes are nearly finished and ready for sale. There is some demand for banisters throughout the year for renovations. However, this business is concentrated in the fall and quickly dies off before Christmas. Any problems with the banisters should be resolved before the peak season begins. On Monday Frank met with Tom Smythe, the vice president of the division, and voiced his concerns. Frank suggested that they meet again on Friday to discuss some fur- ther actions to get back on track. Tom felt the concerns were a bit premature but agreed grudgingly. Tom felt that some of his key people should attend, so Brian Coulter, the sales manager, Pete Harburg, who was in charge of the five two-man installation crews, and Hank Strong, the manufacturing supervisor, were invited to attend. During the meeting, Tom asked each one of his people to describe their individual concerns about the past week's installation report. Hank began by giving a brief outline of the manufacturing process that he was re- sponsible for in the plant Installation Department Monthly Report-August 8. Job Crew Budget S 1.100 Actual $ 7156 1 1.127 Waited 1/2 hr for customer Handrail Area 1. The oak was purchased in 16-foot lengths and inspected for any flaws or excessive knots to ensure it was #1 grade. 2. Any rejects were sent to the cabinet division to be used for interior shelves or to make spindles. 3. The approved boards were run through a multihead mill that planed the bottom side and shaped the top and sides of the handrail. 7157 985 1.154 Fit problem with spindles 7158 5 1,200 996 7160 4 1.500 1.854 7163 2 2 850 865 7166 5 1.200 1,385 Recalled for loose spindle Two split spindles Fit problem with spindles Customer changed design refit Spindle shims needed 7167 1 1.450 1.620 7168 4 1,800 2.254 7169 5 1.100 1.080 7171 2 980 1.200 7172 4 1,560 1.860 7174 1 1.200 1.650 4. They were inspected again for rough grain and any knots that could cause quality problems. Any rejects were then cut into shorter usable lengths for shorter handrails or spindles, 5. The handrails were then sent to the drilling machine where the holes were automati- cally spaced and drilled by the operator on an industrial quality drill press. 6. Occasionally the operator inspects the dimensions of the holes using a dual purpose goo-go gauge. On one end of the gauge is a metal rod that is inserted in the hole to measure the depth. The rod has a hatch marked area that has PASS stamped into the metal. If the top of the hole is in the PASS area, then the hole dimension is considered okay. The other end of the gauge is long and round and has three steps cut into the cir- cumference. This makes the rod get bigger around at about from the end and from the end. If the first part goes into the hole but not the middle, the hole is undersized. If the second step but not the third enters the hole, the hole is of the correct diameter. The third step indicates oversize. 7. The handrails are then sent for sanding and varnishing. A final inspection is per- formed for appearance and finish. The handrail sections are then sorted by length for full size and shorts. 7175 2 975 1.320 7177 4 1.400 1.875 Handrail rough finish Loose spindles Not to drawings Handrail cracked Fit problem spindles Recalled for loose Lannister Fit problem spindles Fit problem spindles Customer changed design 7179 3 2.250 1,900 3.200 2.520 7181 5 7182 3 1.800 2.260 1.780 7184 3 1.750 TOTAL $25,000 530.000 Inspection Report-Spindle The following figure shows the specified depth and allowable tolerance for the pilot study on spindle fit using the knife-edge gauge designed for this purpose (see Figure 16.19). The following 50 readings have been taken and recorded as of August 14 (see Figures 16.20 and 16.21). Spindle Area 1. Oak is purchased, inspected, and cut to length. Approximately 5% also comes from the handrail area. 2. Sections are placed on a planer and run through twice to give the square end dimen- sions. Pieces are then placed into a pattern lathe, which provides the product with the spindle design and tapered top end. The operator also lightly sands the spindle while it is on the lathe. 3. An occasional inspection is performed using a goo-go gauge. The inspection procedure requires the operator to fit over the end of a spindle a gauge, which is an aluminum bar with a specified hole size. The spindle will pass inspection ifto inch of spindle protrudes through the gauge. The gauge is actually marked with red paint outside the limits to assist the operator when inspecting 4. The operator sets the pre-angled cutter to maintain the desired size of the spindle end. 5. The approved spindles are then sent to final sanding and varnishing and final inspection Spindle Test B Dimension A A.65 +/-01 inches B 1 inch FIGURE 16.19 Hank felt that his people did the best job possible given the wood and machinery available. Brian Coulter, the sales manager, felt that his people were certainly doing their jobs since sales had increased at a rate of 15% over the last 3 years. One major concern that Brian did have was the increased number of complaints from his major customer, Lincoln Homes, for the quality of the installations. They have already told Brian they will take their business elsewhere if the quality does not improve immediately. Pete was the most vocal of the group, since his area was always getting the flack He felt his crews were being pushed as hard as possible but just couldn't keep on plan. Accent Oak banisters are designed to be easily installed in the field even for custom work. However, crews seem to have to refit every other piece and spend time chasing defects. Pete recently started having his crew keep track of reasons why they were over- or under- budget on each job. Frank angrily told everyone that he didn't care whose fault the problems were, he just wanted them fixed yesterday and stomped out of the room. Tom and his group had just recently completed a quality management course, and all agreed that they might as well see if it could help them solve the problem and get Frank off their backs. Spindle Widths-Inches .60 63 .60 .62 60 .61 .67 .57 .61 .62 59 .61 .64 67 16 .69 .619 68 .61 67 .68 .67 60 .68 .62 .60 66 163 .62 .67 62 70 67 .68 .58 .69 58 . .65 59 .64 FIGURE 16.20 Hole Diameters-Inches .57 56 58 59 56 58 57 .58 59 .60 57 .61 58 55 .58 .58 60 57 61 .57 59 .55 57 .59 57 38 .56 60 .56 62 .39 38 .62 .57 62 .59 61 .63 39 60 .61 FIGURE 16.21