Question: What is the cost difference between Fergoson's proposal to order 4 cases each time and Patrachalski's proposal to order 32 cases each time? 2. Silo

What is the cost difference between Fergoson's proposal to order 4 cases each time and Patrachalski's proposal to order 32 cases each time?

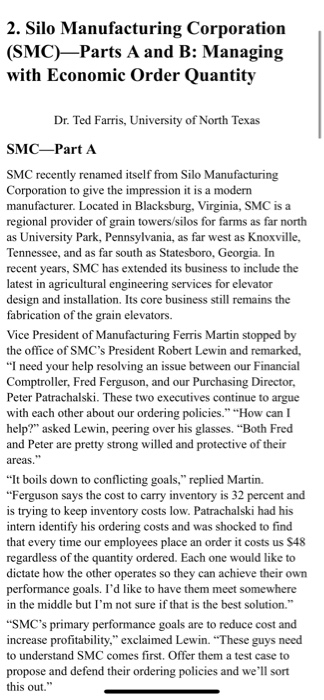

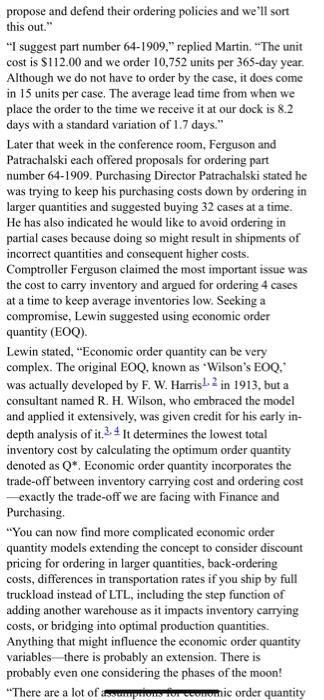

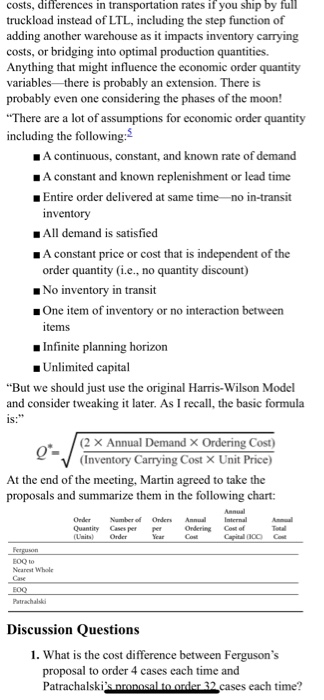

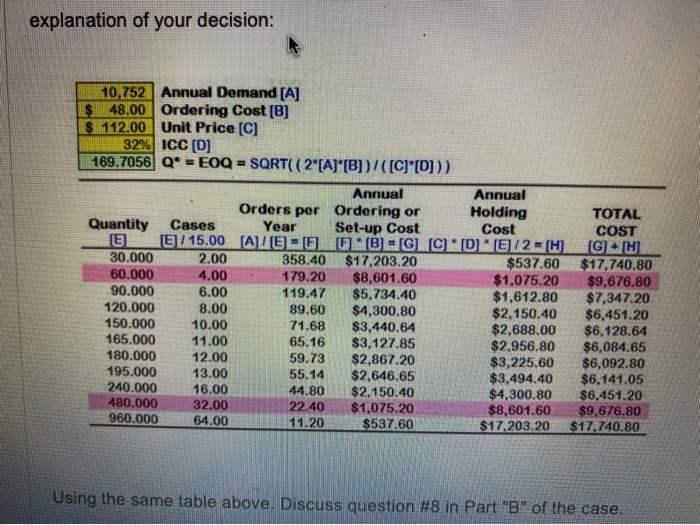

2. Silo Manufacturing Corporation (SMC)-Parts A and B: Managing with Economic Order Quantity Dr. Ted Farris, University of North Texas SMC-Part A SMC recently renamed itself from Silo Manufacturing Corporation to give the impression it is a modern manufacturer. Located in Blacksburg, Virginia, SMC is a regional provider of grain towers/silos for farms as far north as University Park, Pennsylvania, as far west as Knoxville, Tennessee, and as far south as Statesboro, Georgia. In recent years, SMC has extended its business to include the latest in agricultural engineering services for elevator design and installation. Its core business still remains the fabrication of the grain elevators. Vice President of Manufacturing Ferris Martin stopped by the office of SMC's President Robert Lewin and remarked, "I need your help resolving an issue between our Financial Comptroller, Fred Ferguson, and our Purchasing Director, Peter Patrachalski. These two executives continue to argue with each other about our ordering policies." "How can I help?" asked Lewin, peering over his glasses. Both Fred and Peter are pretty strong willed and protective of their areas." "It boils down to conflicting goals," replied Martin. "Ferguson says the cost to carry inventory is 32 percent and is trying to keep inventory costs low. Patrachalski had his intern identify his ordering costs and was shocked to find that every time our employees place an order it costs us $48 regardless of the quantity ordered. Each one would like to dictate how the other operates so they can achieve their own performance goals. I'd like to have them meet somewhere in the middle but I'm not sure if that is the best solution." "SMC's primary performance goals are to reduce cost and increase profitability," exclaimed Lewin. These guys need to understand SMC comes first. Offer them a test case to propose and defend their ordering policies and we'll sort this out." propose and defend their ordering policies and we'll sort this out." "I suggest part number 64-1909," replied Martin. The unit cost is $112.00 and we order 10,752 units per 365-day year. Although we do not have to order by the case, it does come in 15 units per case. The average lead time from when we place the order to the time we receive it at our dock is 8.2 days with a standard variation of 1.7 days." Later that week in the conference room, Ferguson and Patrachalski each offered proposals for ordering part number 64-1909. Purchasing Director Patrachalski stated he was trying to keep his purchasing costs down by ordering in larger quantities and suggested buying 32 cases at a time. He has also indicated he would like to avoid ordering in partial cases because doing so might result in shipments of incorrect quantities and consequent higher costs. Comptroller Ferguson claimed the most important issue was the cost to carry inventory and argued for ordering 4 cases at a time to keep average inventories low. Seeking a compromise, Lewin suggested using economic order quantity (EOQ). Lewin stated, Economic order quantity can be very complex. The original EOQ, known as "Wilson's EOQ, was actually developed by F. W. Harrisl. 2 in 1913, but a consultant named R. H. Wilson, who embraced the model and applied it extensively, was given credit for his early in- depth analysis of it.2.4 It determines the lowest total inventory cost by calculating the optimum order quantity denoted as Q*. Economic order quantity incorporates the trade-off between inventory carrying cost and ordering cost exactly the trade-off we are facing with Finance and Purchasing, "You can now find more complicated economic order quantity models extending the concept to consider discount pricing for ordering in larger quantities, back-ordering costs, differences in transportation rates if you ship by full truckload instead of LTL, including the step function of adding another warehouse as it impacts inventory carrying costs, or bridging into optimal production quantities. Anything that might influence the economic order quantity variablesthere is probably an extension. There is probably even one considering the phases of the moon! "There are a lot of insumption reconomic order quantity costs, differences in transportation rates if you ship by full truckload instead of LTL, including the step function of adding another warehouse as it impacts inventory carrying costs, or bridging into optimal production quantities. Anything that might influence the economic order quantity variables there is probably an extension. There is probably even one considering the phases of the moon! "There are a lot of assumptions for economic order quantity including the following: A continuous, constant, and known rate of demand A constant and known replenishment or lead time Entire order delivered at same time no in-transit inventory All demand is satisfied A constant price or cost that is independent of the order quantity (i.e., no quantity discount) No inventory in transit One item of inventory or no interaction between items Infinite planning horizon Unlimited capital But we should just use the original Harris-Wilson Model and consider tweaking it later. As I recall, the basic formula is:" (2 x Annual Demand X Ordering Cost) (Inventory Carrying Cost x Unit Price) At the end of the meeting, Martin agreed to take the proposals and summarize them in the following chart: Annu Number of Orders Annual internal Quantity Cases per per Ordering Cost of (Units) Gaul Capital (100 C Onder Onder Ferguson EOQ.10 Nearest Whole E0Q Parachalski Discussion Questions 1. What is the cost difference between Ferguson's proposal to order 4 cases each time and Patrachalski's proposal to order 32 cases each time? explanation of your decision: 10,752 Annual Demand [A] S48.00 Ordering Cost [B] S 112.00 Unit Price [C] 32% ICC (D) 169.7056 Q* EOQ = SQRT(( 2"[A]"[B])/([C]"[0])) Annual Annual Orders per Ordering or Holding Quantity Cases Year Set-up Cost Cost E E15.00 (AZE) - ( CCC (B-G ( COME 12-H 30.000 2.00 358.40 $17,203.20 $537.60 60.000 4.00 179.20 $8,601.60 $1,075.20 90.000 6.00 119.47 $5,734.40 $1,612.80 120.000 8.00 89.60 $4,300.80 $2,150.40 150.000 10.00 71.68 $3,440.64 $2,688.00 165.000 11.00 65.16 $3,127.85 $2.956.80 180.000 12.00 59.73 $2,867.20 $3,225.60 195.000 13.00 55.14 $2,646.65 $3,494.40 240.000 16.00 44.80 $2,150.40 $4,300.80 480.000 32.00 22.40 $1,075,20 $8,601.60 960.000 64.00 11.20 $537.60 $17.203.20 TOTAL COST ( GH) $17,740.80 $9,676.80 $7,347.20 $6,451.20 $6.128.64 $6,084.65 $6,092.80 $6.141.05 $6,451.20 $9,676.80 $17.740.80 Using the same table above. Discuss question #8 in Part "B" of the case