Question: What prerequisite assessment needs to be carried out before improving a facility layout? Explain this assessment for ABC Shipyard. Page 2 9B16D023 deadweight tonnes (DWT);'

What prerequisite assessment needs to be carried out before improving a facility layout? Explain this assessment for ABC Shipyard.

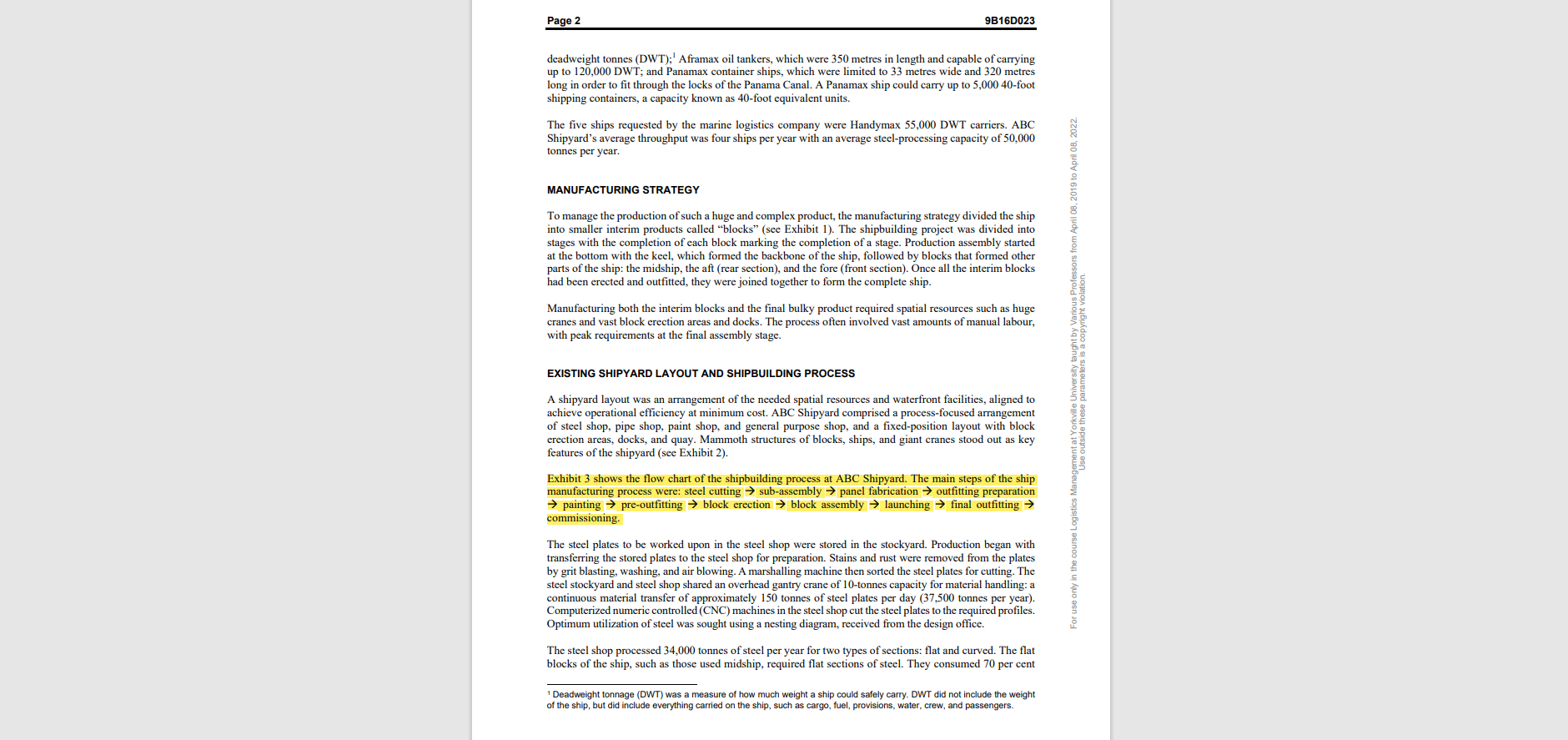

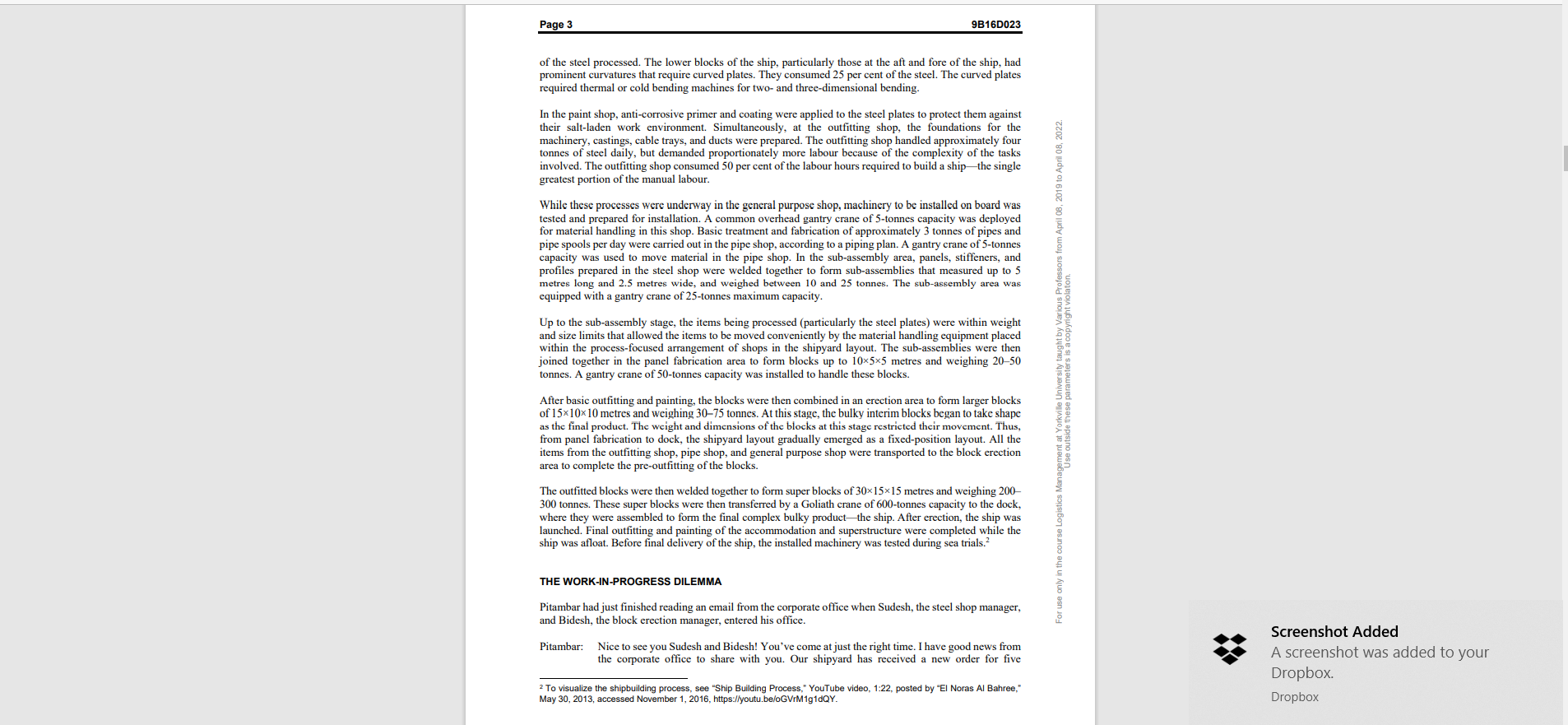

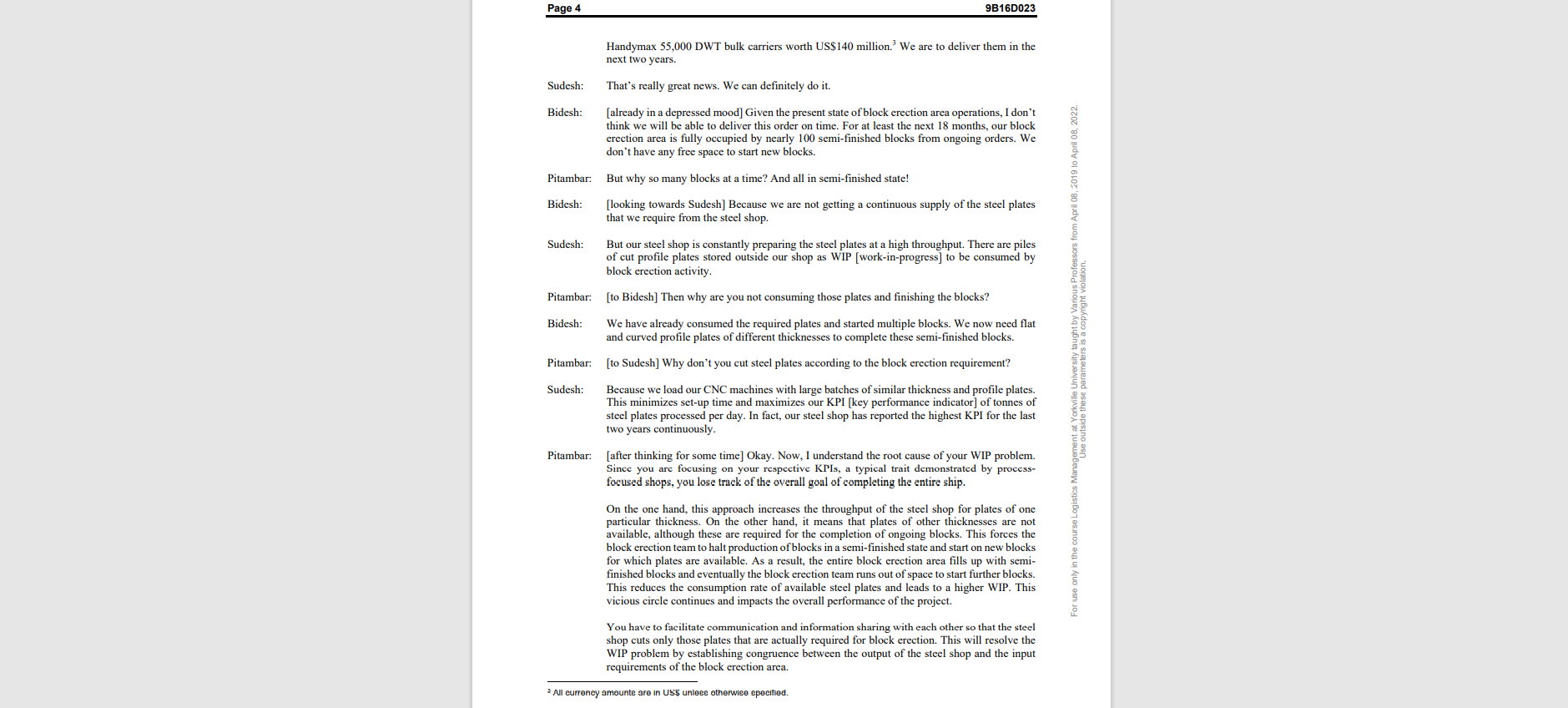

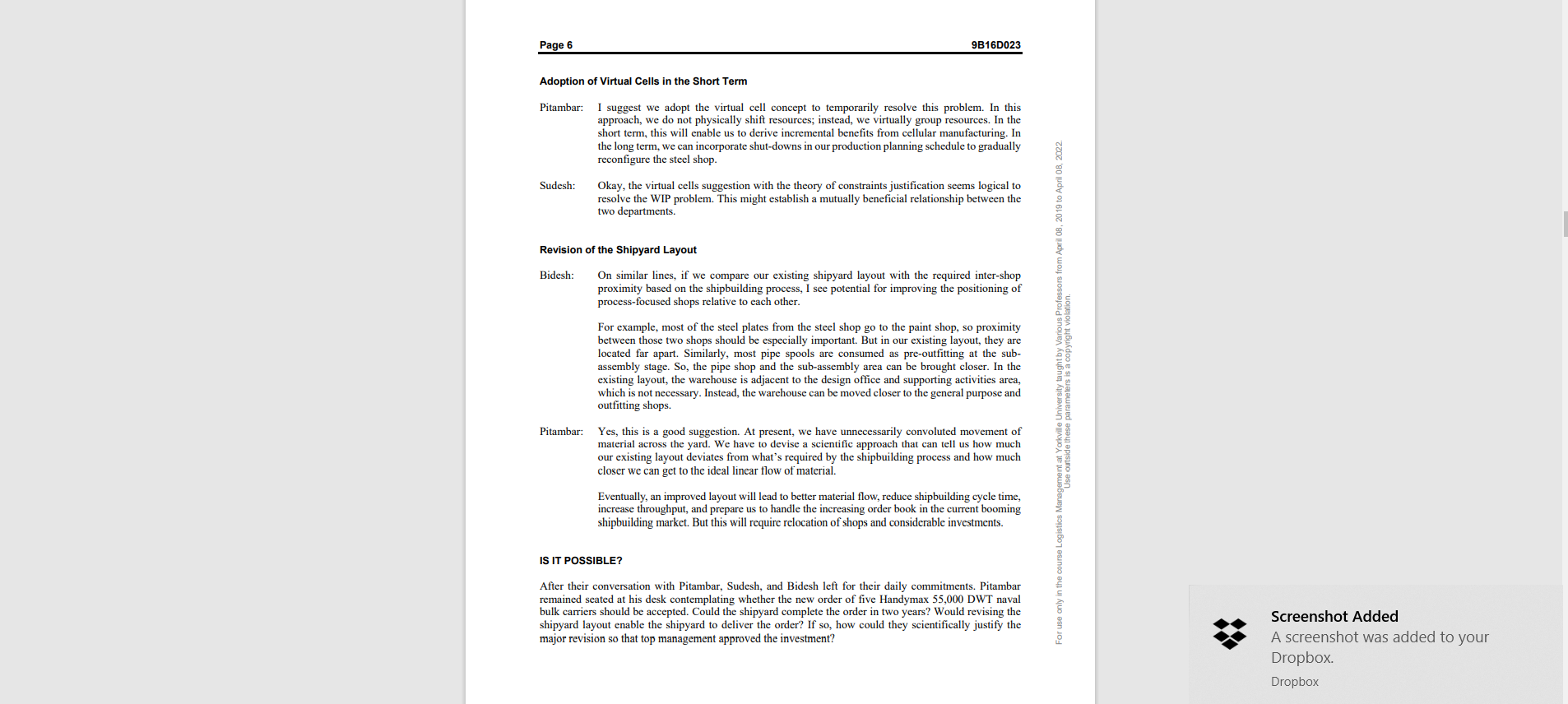

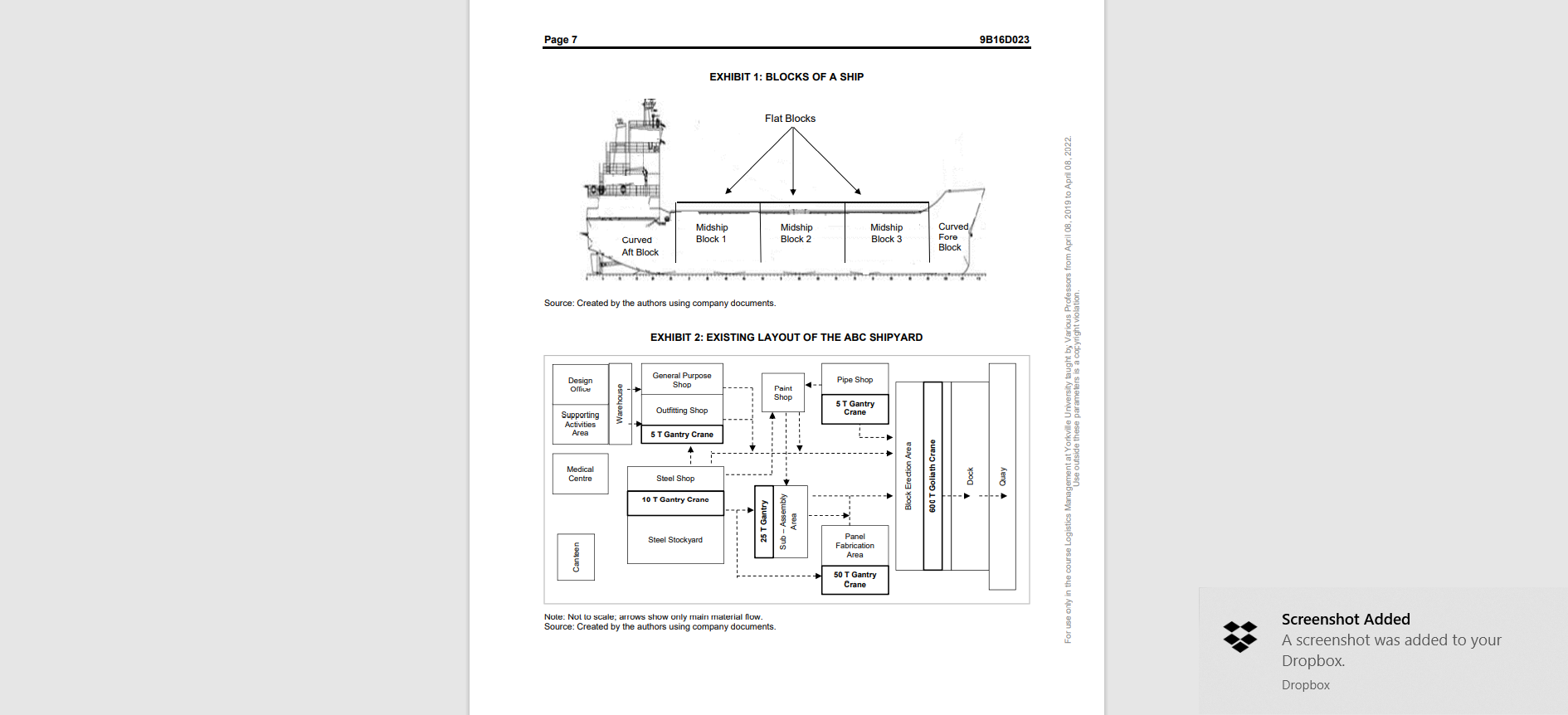

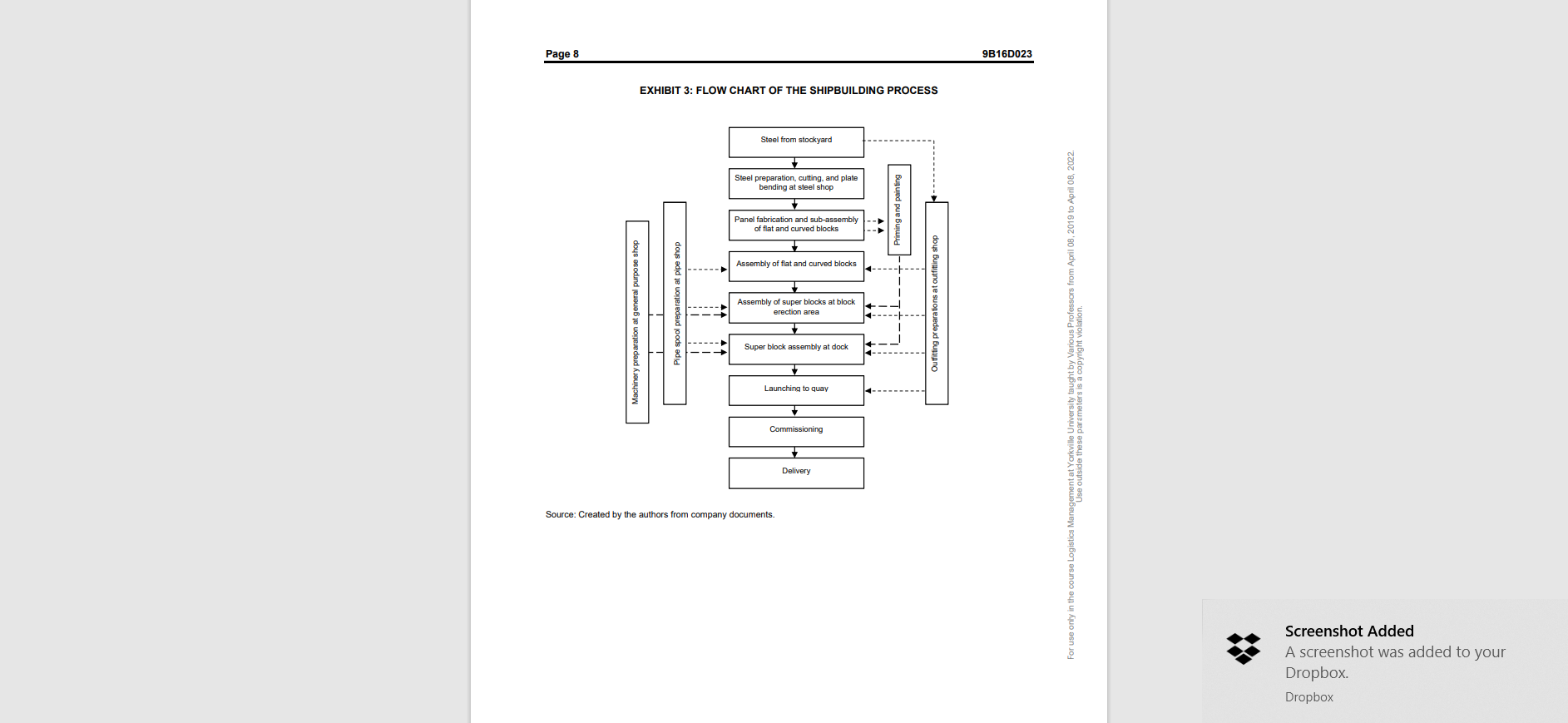

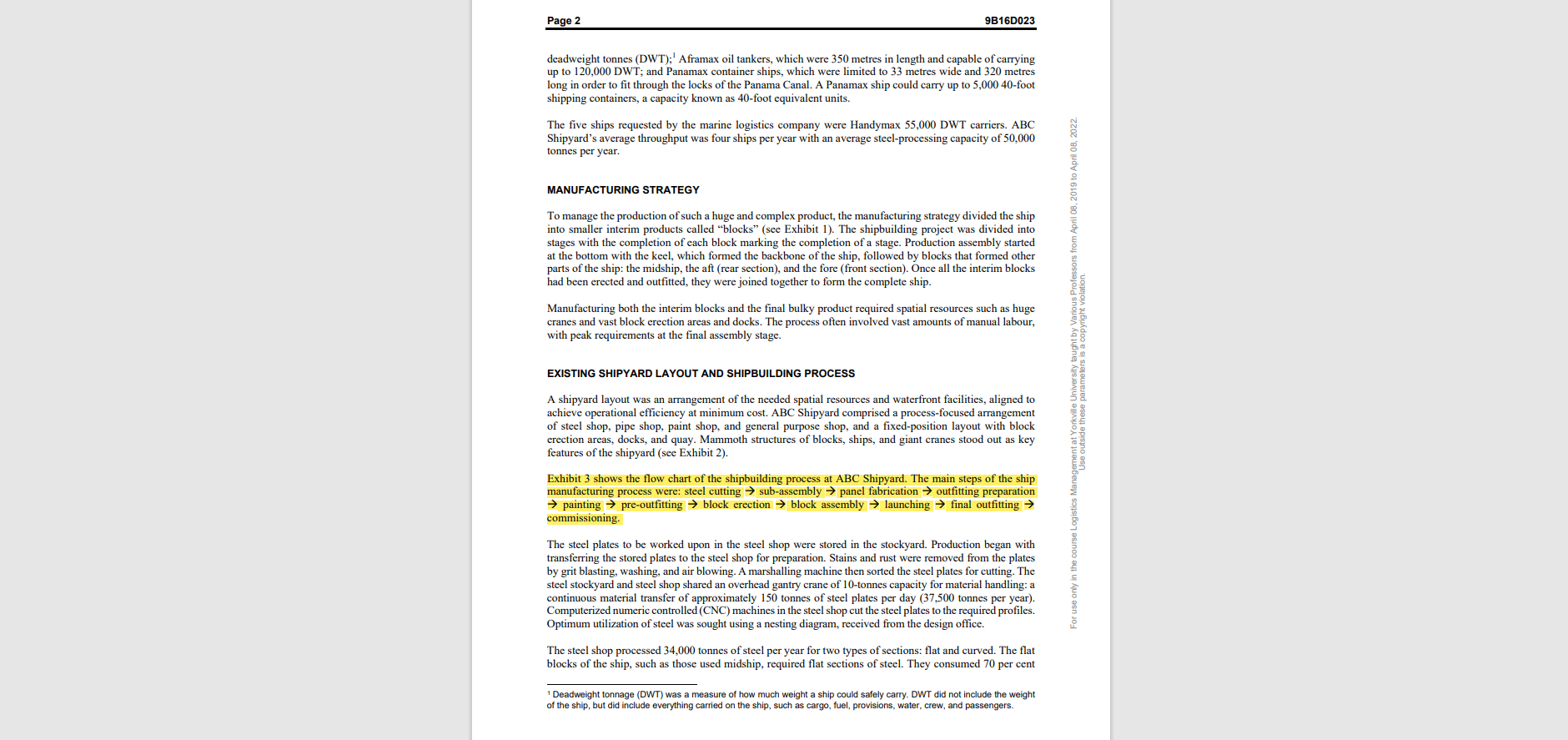

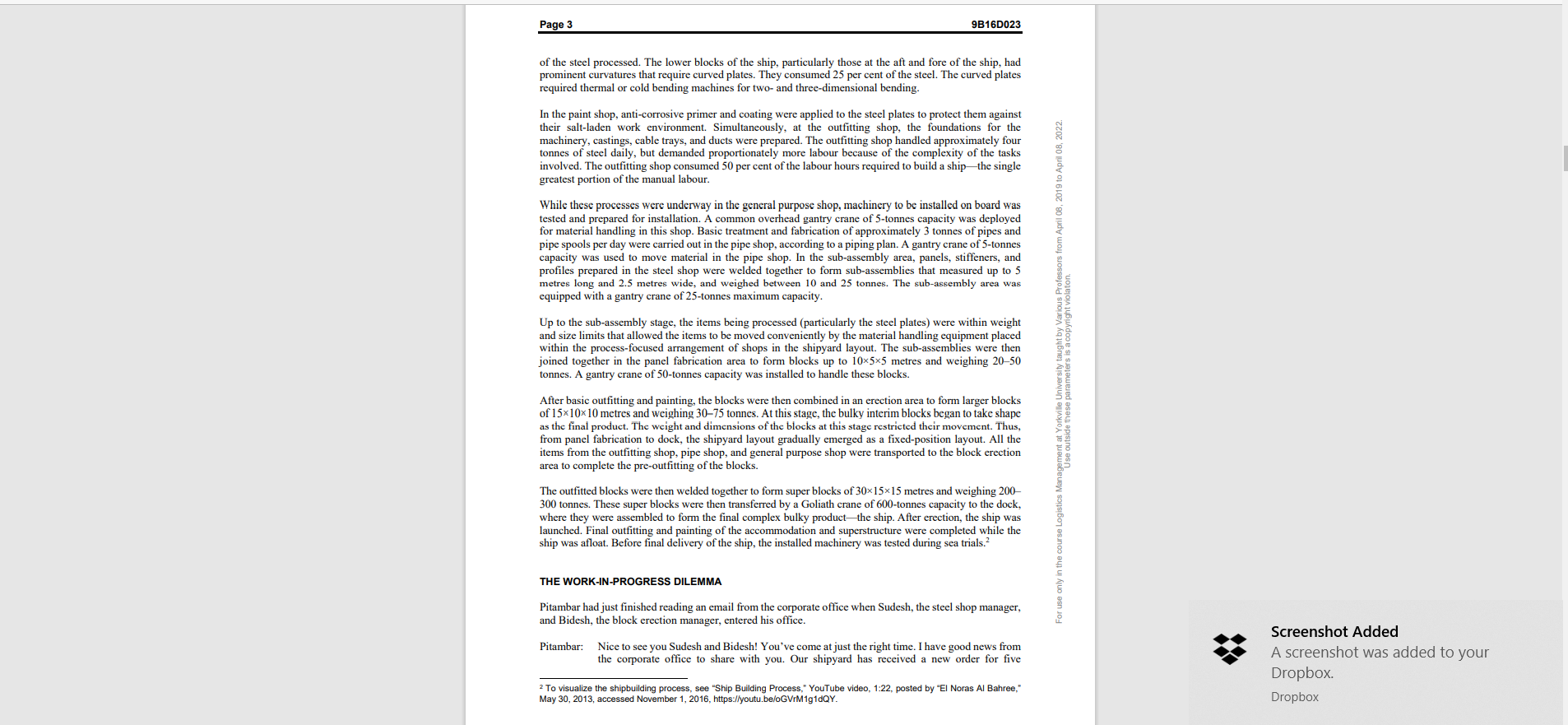

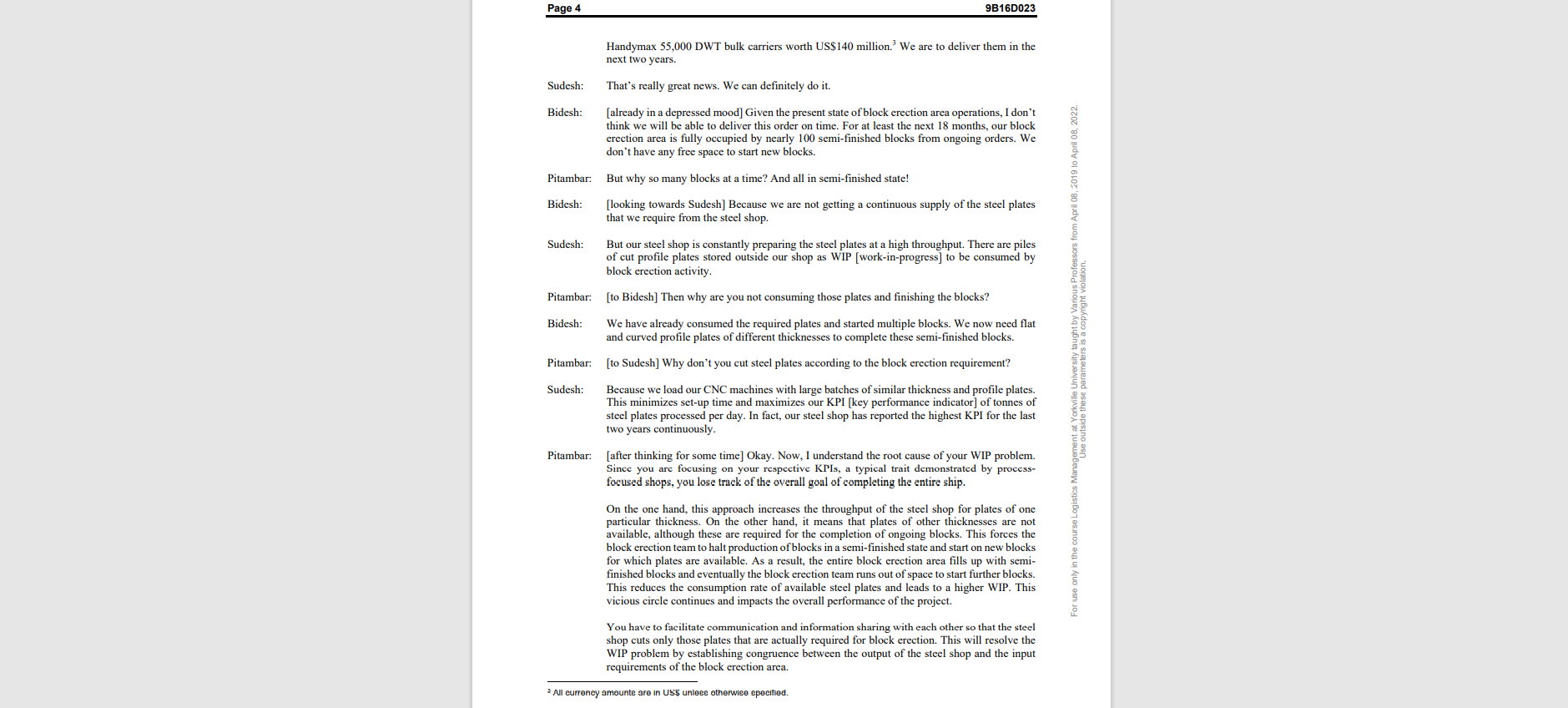

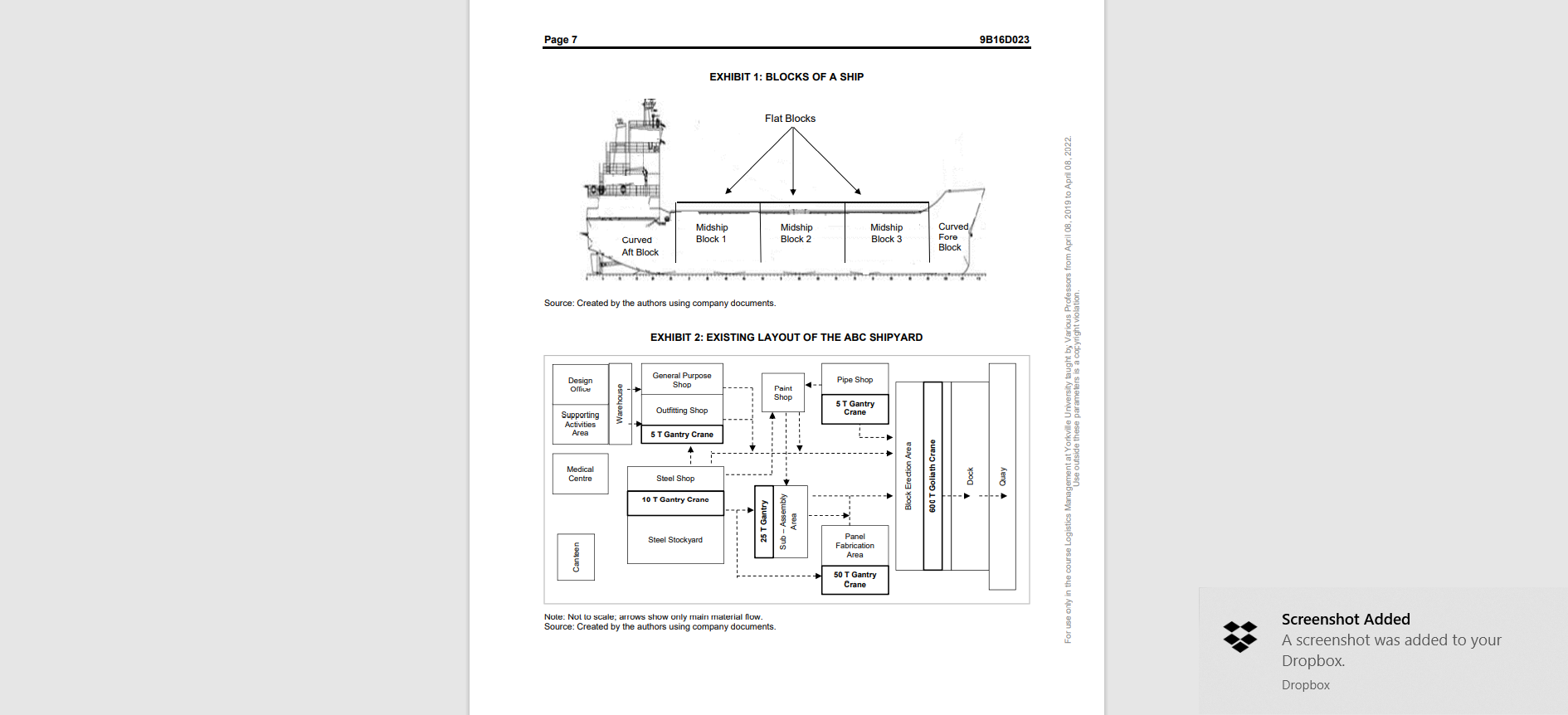

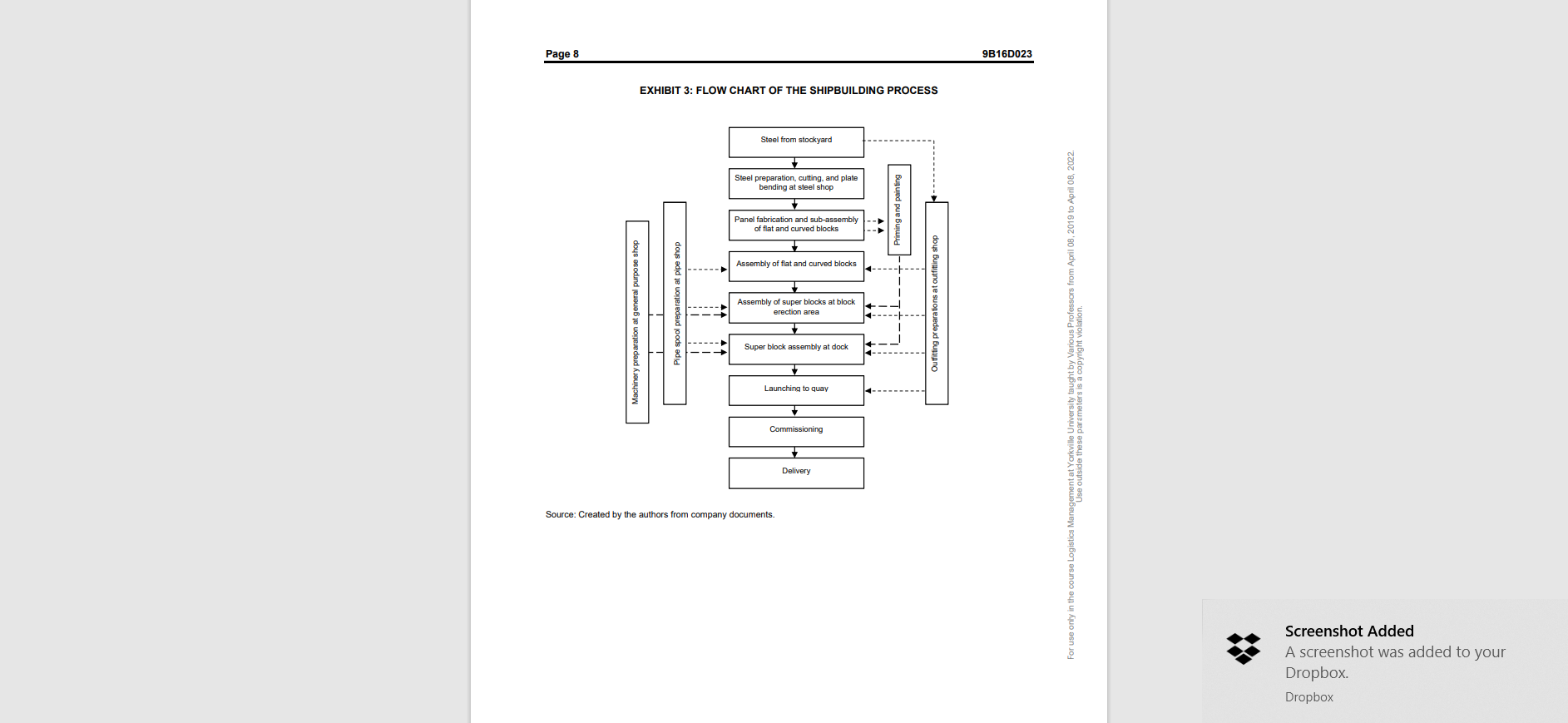

Page 2 9B16D023 deadweight tonnes (DWT);' Aframax oil tankers, which were 350 metres in length and capable of carrying up to 120,000 DWT, and Panamax container ships, which were limited to 33 metres wide and 320 metres long in order to fit through the locks of the Panama Canal. A Panamax ship could carry up to 5,000 40-foot shipping containers, a capacity known as 40-foot equivalent units. The five ships requested by the marine logistics company were Handymax 55,000 DWT carriers. ABC Shipyard's average throughput was four ships per year with an average steel-processing capacity of 50,000 tonnes per year. MANUFACTURING STRATEGY To manage the production of such a huge and complex product, the manufacturing strategy divided the ship into smaller interim products called "blocks (see Exhibit 1). The shipbuilding project was divided into stages with the completion of each block marking the completion of a stage. Production assembly started at the bottom with the keel, which formed the backbone of the ship, followed by blocks that formed other parts of the ship: the midship, the aft (rear section), and the fore (front section). Once all the interim blocks had been erected and outfitted, they were joined together to form the complete ship. Use outside these parameters is a copyright violationssors from April 08, 2019 to April 08, 2022. Manufacturing both the interim blocks and the final bulky product required spatial resources such as huge cranes and vast block erection areas and docks. The process often involved vast amounts of manual labour, with peak requirements at the final assembly stage. EXISTING SHIPYARD LAYOUT AND SHIPBUILDING PROCESS A shipyard layout was an arrangement of the needed spatial resources and waterfront facilities, aligned to achieve operational efficiency at minimum cost. ABC Shipyard comprised a process-focused arrangement of steel shop, pipe shop, paint shop, and general purpose shop, and a fixed-position layout with block erection areas, docks, and quay. Mammoth structures of blocks, ships, and giant cranes stood out as key features of the shipyard (see Exhibit 2). Exhibit 3 shows the flow chart of the shipbuilding process at ABC Shipyard. The main steps of the ship manufacturing process were: steel cutting sub-assembly panel fabrication outfitting preparation painting pre-outfitting block erection block assembly launching final outfitting commissioning. The steel plates to be worked upon in the steel shop were stored in the stockyard. Production began with transferring the stored plates to the steel shop for preparation. Stains and rust were removed from the plates by grit blasting, washing, and air blowing. A marshalling machine then sorted the steel plates for cutting. The steel stockyard and steel shop shared an overhead gantry crane of 10-tonnes capacity for material handling: a continuous material transfer of approximately 150 tonnes of steel plates per day (37,500 tonnes per year). Computerized numeric controlled (CNC) machines in the steel shop cut the steel plates to the required profiles. Optimum utilization of steel was sought using a nesting diagram, received from the design office. For use only in the course Logistics The steel shop processed 34,000 tonnes of steel per year for two types of sections: flat and curved. The flat blocks of the ship, such as those used midship, required flat sections of steel. They consumed 70 per cent Deadweight tonnage (DWT) was a measure of how much weight a ship could safely carry. DWT did not include the weight of the ship, but did include everything carried on the ship, such as cargo, fuel, provisions, water, crew, and passengers. Page 3 9B16D023 of the steel processed. The lower blocks of the ship, particularly those at the aft and fore of the ship, had prominent curvatures that require curved plates. They consumed 25 per cent of the steel. The curved plates required thermal or cold bending machines for two-and three-dimensional bending. violations from April 08, 2019 to April 08, 2022 In the paint shop, anti-corrosive primer and coating were applied to the steel plates to protect them against their salt-laden work environment. Simultaneously, at the outfitting shop, the foundations for the machinery, castings, cable trays, and ducts were prepared. The outfitting shop handled approximately four tonnes of steel daily, but demanded proportionately more labour because of the complexity of the tasks involved. The outfitting shop consumed 50 per cent of the labour hours required to build a shipthe single greatest portion of the manual labour. While these processes were underway in the general purpose shop, machinery to be installed on board was tested and prepared for installation. A common overhead gantry crane of 5-tonnes capacity was deployed for material handling in this shop. Basic treatment and fabrication of approximately 3 tonnes of pipes and pipe spools per day were carried out in the pipe shop, according to a piping plan. A gantry crane of 5-tonnes capacity was used to move material in the pipe shop. In the sub-assembly area, panels, stiffeners, and profiles prepared in the steel shop were welded together to form sub-assemblies that measured up to 5 metres long and 2.5 metres wide, and weighed between 10 and 25 tonnes. The sub-assembly area was equipped with a gantry crane of 25-tonnes maximum capacity. Up to the sub-assembly stage, the items being processed (particularly the steel plates) were within weight and size limits that allowed the items to be moved conveniently by the material handling equipment placed within the process focused arrangement of shops in the shipyard layout. The sub-assemblies were then joined together in the panel fabrication area to form blocks up to 10x5x5 metres and weighing 20-50 tonnes. A gantry crane of 50-tonnes capacity was installed to handle these blocks. After basic outfitting and painting, the blocks were then combined in an erection area to form larger blocks of 15x10x10 metres and weighing 30-75 tonnes. At this stage, the bulky interim blocks began to take shape as the final product. The weight and dimensions of the blocks at this stage restricted their movement. Thus, from panel fabrication to dock, the shipyard layout gradually emerged as a fixed-position layout. All the items from the outfitting shop, pipe shop, and general purpose shop were transported to the block erection area to complete the pre-outfitting of the blocks. The outfitted blocks were then welded together to form super blocks of 30x15x15 metres and weighing 200 300 tonnes. These super blocks were then transferred by a Goliath crane of 600-tonnes capacity to the dock, where they were assembled to form the final complex bulky product-the ship. After erection, the ship was launched. Final outfitting and painting of the accommodation and superstructure were completed while the ship was afloat. Before final delivery of the ship, the installed machinery was tested during sea trials.? or use only in the course Logistics ManaUse outside THE WORK-IN-PROGRESS DILEMMA Pitambar had just finished reading an email from the corporate office when Sudesh, the steel shop manager, and Bidesh, the block erection manager, entered his office. Pitambar: Nice to see you Sudesh and Bidesh! You've come at just the right time. I have good news from the corporate office to share with you. Our shipyard has received a new order for five Screenshot Added A screenshot was added to your Dropbox. Dropbox 2 To visualize the shipbuilding process, see "Ship Building Process," YouTube video, 1:22, posted by "El Noras Al Bahree." May 30, 2013, accessed November 1, 2016, https://youtu.be/oGVrM191dQY. Page 4 9B16D023 Handymax 55,000 DWT bulk carriers worth US$140 million. We are to deliver them in the next two years. Sudesh: That's really great news. We can definitely do it. Bidesh: (already in a depressed mood] Given the present state of block erection area operations, I don't think we will be able to deliver this order on time. For at least the next 18 months, our block erection area is fully occupied by nearly 100 semi-finished blocks from ongoing orders. We don't have any free space to start new blocks. Pitambar: But why so many blocks at a time? And all in semi-finished state! Bidesh: [looking towards Sudesh] Because we are not getting a continuous supply of the steel plates that we require from the steel shop. yright violations from April 18, 2019 to April 08, 2022. Sudesh: But our steel shop is constantly preparing the steel plates at a high throughput. There are piles of cut profile plates stored outside our shop as WIP (work-in-progress) to be consumed by block erection activity. Pitambar [to Bidesh] Then why are you not consuming those plates and finishing the blocks? Bidesh: We have already consumed the required plates and started multiple blocks. We now need flat and curved profile plates of different thicknesses to complete these semi-finished blocks. [to Sudesh] Why don't you cut steel plates according to the block erection requirement? Pitambar: Sudesh: Because we load our CNC machines with large batches of similar thickness and profile plates. This minimizes set-up time and maximizes our KPI [key performance indicator of tonnes of steel plates processed per day. In fact, our steel shop has reported the highest KPI for the last two years continuously. Pitambar: (after thinking for some time] Okay. Now, I understand the root cause of your WIP problem. Since you are focusing on your respective KPIs, a typical trait demonstrated by process- focused shops, you lose track of the overall goal of completing the entire ship. On the one hand, this approach increases the throughput of the steel shop for plates of one particular thickness. On the other hand, it means that plates of other thicknesses are not available, although these are required for the completion of ongoing blocks. This forces the block erection team to halt production of blocks in a semi-finished state and start on new blocks for which plates are available. As a result, the entire block erection area fills up with semi- finished blocks and eventually the block erection team runs out of space to start further blocks. This reduces the consumption rate of available steel plates and leads to a higher WIP. This vicious circle continues and impacts the overall performance of the project. You have to facilitate communication and information sharing with each other so that the steel shop cuts only those plates that are actually required for block erection. This will resolve the WIP problem by establishing congruence between the output of the steel shop and the input requirements of the block erection area. All eurrency amounte are in US$ unleee otherwiee epecified. Page 5 9B16D023 Bidesh: That's a good solution. It will help us to finish the interim product as a complete block before starting a new block. Sudesh: But I foresee a challenge to establishing this congruence between output and input (from the steel shop to block erection). To suit the varying demands of block erection, the steel shop will have to set up its machines more often. This will have a negative impact on our KPI. So, why should we sacrifice our KPI to benefit block erection? To ensure long-term solution, the arrangement should be mutually beneficial. The Theory of Constraints Pitambar: yright violation, as from April 08, 2019 to April 08,2022. Let me explain this from a theory of constraints perspective. In a relationship, the two entities should understand each other's strengths and weaknesses. If we analyze the production process closely, we will realize that initial stages of production like steel preparation, steel cutting, and sub-assembly are very similar for all types of ships. The strength of the steel shop is that its processes are mostly repetitive; thus, it has an opportunity to benefit from economies of scale. However, at the block erection stage, there is a clear differentiation based on ship type. The complexity of the tasks involved and the necessary skill level increase as the assembly of blocks commences. On top of this, construction of super blocks and the final ship require spatial resources like a block erection area, a heavy capacity Goliath crane, and a dockall fixed in position. The block erection area and the dock limit the throughput of the shipyard. We cannot increase the capacity of these constrained resources in the short term as they are very costly options. According to the theory of constraints, the identified constrained resource should be fully utilized and every other decision should be subordinated to it. In our production system, the block erection area is the constrained resource. So, ensure its maximum utilization, decisions regarding output of its predecessorthe steel shop-should be governed by the input requirements of the constrained resource. Product-Focused Layout of the Steel Shop Pitambar: I have a solution to decrease the number of set-ups needed in the steel shop, while still satisfying the block erection requirements. The steel shop performs the maximum number of set-ups when it changes product from flat plates to curved plates. So, if we can identify and group dedicated machines in the steel shop according to product families, we'll have two cells: a flat-block line and a curved-block line. Then we can orient the layout by product and get a linear flow of material. This would minimize material movement and reduce the number of set-ups. For use cnly in th Sudesh: So, inside the broad process focused layout of our shipyard, we will have semi-self-contained work cellsa product-focused layout inside a process focused steel shop. This is interesting! But again there is a problem. To configure these cells, machinery has to be shifted, and this will stall daily production activities. This is not possible now because production of two ships is underway at our yard. Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 5 9B16D023 Bidesh: That's a good solution. It will help us to finish the interim product as a complete block before starting a new block. Sudesh: But I foresee a challenge to establishing this congruence between output and input (from the steel shop to block erection). To suit the varying demands of block erection, the steel shop will have to set up its machines more often. This will have a negative impact on our KPI. So, why should we sacrifice our KPI to benefit block erection? To ensure long-term solution, the arrangement should be mutually beneficial. The Theory of Constraints Pitambar: yright violation, as from April 08, 2019 to April 08,2022. Let me explain this from a theory of constraints perspective. In a relationship, the two entities should understand each other's strengths and weaknesses. If we analyze the production process closely, we will realize that initial stages of production like steel preparation, steel cutting, and sub-assembly are very similar for all types of ships. The strength of the steel shop is that its processes are mostly repetitive; thus, it has an opportunity to benefit from economies of scale. However, at the block erection stage, there is a clear differentiation based on ship type. The complexity of the tasks involved and the necessary skill level increase as the assembly of blocks commences. On top of this, construction of super blocks and the final ship require spatial resources like a block erection area, a heavy capacity Goliath crane, and a dockall fixed in position. The block erection area and the dock limit the throughput of the shipyard. We cannot increase the capacity of these constrained resources in the short term as they are very costly options. According to the theory of constraints, the identified constrained resource should be fully utilized and every other decision should be subordinated to it. In our production system, the block erection area is the constrained resource. So, ensure its maximum utilization, decisions regarding output of its predecessorthe steel shop-should be governed by the input requirements of the constrained resource. Product-Focused Layout of the Steel Shop Pitambar: I have a solution to decrease the number of set-ups needed in the steel shop, while still satisfying the block erection requirements. The steel shop performs the maximum number of set-ups when it changes product from flat plates to curved plates. So, if we can identify and group dedicated machines in the steel shop according to product families, we'll have two cells: a flat-block line and a curved-block line. Then we can orient the layout by product and get a linear flow of material. This would minimize material movement and reduce the number of set-ups. For use cnly in th Sudesh: So, inside the broad process focused layout of our shipyard, we will have semi-self-contained work cellsa product-focused layout inside a process focused steel shop. This is interesting! But again there is a problem. To configure these cells, machinery has to be shifted, and this will stall daily production activities. This is not possible now because production of two ships is underway at our yard. Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 6 9B16D023 Adoption of Virtual Cells in the Short Term Pitambar: I suggest we adopt the virtual cell concept to temporarily resolve this problem. In this approach, we do not physically shift resources; instead, we virtually group resources. In the short term, this will enable us to derive incremental benefits from cellular manufacturing. In the long term, we can incorporate shut-downs in our production planning schedule to gradually reconfigure the steel shop. Sudesh: Okay, the virtual cells suggestion with the theory of constraints justification seems logical to resolve the WIP problem. This might establish a mutually beneficial relationship between the two departments. April 08, 2019 to April 08, 2022. Revision of the Shipyard Layout Bidesh: On similar lines, if we compare our existing shipyard layout with the required inter-shop proximity based on the shipbuilding process, I see potential for improving the positioning of process-focused shops relative to each other. For example, most of the steel plates from the steel shop go to the paint shop, so proximity between those two shops should be especially important. But in our existing layout, they are located far apart. Similarly, most pipe spools are consumed as pre-outfitting at the sub- assembly stage. So, the pipe shop and the sub-assembly area can be brought closer. In the exist the warehous is adjacent to the office and supporting activities area, which is not necessary. Instead, the warehouse can be moved closer to the general purpose and outfitting shops. Pitambar: Yes, this is a good suggestion. At present, we have unnecessarily convoluted movement of material across the yard. We have to devise a scientific approach that can tell us how much our existing layout deviates from what's required by the shipbuilding process and how much closer we can get to the ideal linear flow of material. For use only in the course Logistics ManagUse outside these parameters is a copyright violation Eventually, an improved layout will lead to better material flow, reduce shipbuilding cycle time, increase throughput, and prepare us to handle the increasing order book in the current booming shipbuilding market. But this will require relocation of shops and considerable investments. IS IT POSSIBLE? After their conversation with Pitambar, Sudesh, and Bidesh left for their daily commitments. Pitambar remained seated at his desk contemplating whether the new order of five Handymax 55,000 DWT naval bulk carriers should be accepted. Could the shipyard complete the order in two years? Would revising the shipyard layout enable the shipyard to deliver the order? If so, how could they scientifically justify the major revision so that top management approved the investment? Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 7 9B16D023 EXHIBIT 1: BLOCKS OF A SHIP Flat Blocks Midship Midship Block 1 Midship Block 3 Curved Block 2 Curved Fore Block Aft Block Source: Created by the authors using company documents e outside these parameters is a copyright violatidessors from April 08, 2019 to April 08, 2022. EXHIBIT 2: EXISTING LAYOUT OF THE ABC SHIPYARD Design Orlice General Purpose Shop Pipe Shop Paint Shop Outfitting Shop 5 T Gantry Crane Supporting Activities Area 5 T Gantry Crane Medical Centre Steel Shop 600 T Goliath Crane Block Erection Quay 10 T Gantry Crane 25 T Gant Steel Stockyard 1 Panel Fabrication Area 50 T Gantry Crane Nole: Not to scale; arrows show only main material flow. Source: Created by the authors using company documents. For use only in Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 8 9B16D023 EXHIBIT 3: FLOW CHART OF THE SHIPBUILDING PROCESS Steel from stockyard Steel preparation, cutting, and plate bending at steel shop Priming and painting m April 08, 2019 to April 08, 2022. Panel fabrication and sub-assembly of flat and curved blocks Assembly of flat and curved blocks Pipe spool preparation at pipe shop Assembly of super blocks at block erection area Machinery preparation at general purpose shop Outfitting preparations at outfitting shop Super block assembly at dock Launching quay Commissioning Delivery For use only in the course Logistics Manag Use outside these parameters is a copyright violation Source: Created by the authors from company documents. Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 2 9B16D023 deadweight tonnes (DWT);' Aframax oil tankers, which were 350 metres in length and capable of carrying up to 120,000 DWT, and Panamax container ships, which were limited to 33 metres wide and 320 metres long in order to fit through the locks of the Panama Canal. A Panamax ship could carry up to 5,000 40-foot shipping containers, a capacity known as 40-foot equivalent units. The five ships requested by the marine logistics company were Handymax 55,000 DWT carriers. ABC Shipyard's average throughput was four ships per year with an average steel-processing capacity of 50,000 tonnes per year. MANUFACTURING STRATEGY To manage the production of such a huge and complex product, the manufacturing strategy divided the ship into smaller interim products called "blocks (see Exhibit 1). The shipbuilding project was divided into stages with the completion of each block marking the completion of a stage. Production assembly started at the bottom with the keel, which formed the backbone of the ship, followed by blocks that formed other parts of the ship: the midship, the aft (rear section), and the fore (front section). Once all the interim blocks had been erected and outfitted, they were joined together to form the complete ship. Use outside these parameters is a copyright violationssors from April 08, 2019 to April 08, 2022. Manufacturing both the interim blocks and the final bulky product required spatial resources such as huge cranes and vast block erection areas and docks. The process often involved vast amounts of manual labour, with peak requirements at the final assembly stage. EXISTING SHIPYARD LAYOUT AND SHIPBUILDING PROCESS A shipyard layout was an arrangement of the needed spatial resources and waterfront facilities, aligned to achieve operational efficiency at minimum cost. ABC Shipyard comprised a process-focused arrangement of steel shop, pipe shop, paint shop, and general purpose shop, and a fixed-position layout with block erection areas, docks, and quay. Mammoth structures of blocks, ships, and giant cranes stood out as key features of the shipyard (see Exhibit 2). Exhibit 3 shows the flow chart of the shipbuilding process at ABC Shipyard. The main steps of the ship manufacturing process were: steel cutting sub-assembly panel fabrication outfitting preparation painting pre-outfitting block erection block assembly launching final outfitting commissioning. The steel plates to be worked upon in the steel shop were stored in the stockyard. Production began with transferring the stored plates to the steel shop for preparation. Stains and rust were removed from the plates by grit blasting, washing, and air blowing. A marshalling machine then sorted the steel plates for cutting. The steel stockyard and steel shop shared an overhead gantry crane of 10-tonnes capacity for material handling: a continuous material transfer of approximately 150 tonnes of steel plates per day (37,500 tonnes per year). Computerized numeric controlled (CNC) machines in the steel shop cut the steel plates to the required profiles. Optimum utilization of steel was sought using a nesting diagram, received from the design office. For use only in the course Logistics The steel shop processed 34,000 tonnes of steel per year for two types of sections: flat and curved. The flat blocks of the ship, such as those used midship, required flat sections of steel. They consumed 70 per cent Deadweight tonnage (DWT) was a measure of how much weight a ship could safely carry. DWT did not include the weight of the ship, but did include everything carried on the ship, such as cargo, fuel, provisions, water, crew, and passengers. Page 3 9B16D023 of the steel processed. The lower blocks of the ship, particularly those at the aft and fore of the ship, had prominent curvatures that require curved plates. They consumed 25 per cent of the steel. The curved plates required thermal or cold bending machines for two-and three-dimensional bending. violations from April 08, 2019 to April 08, 2022 In the paint shop, anti-corrosive primer and coating were applied to the steel plates to protect them against their salt-laden work environment. Simultaneously, at the outfitting shop, the foundations for the machinery, castings, cable trays, and ducts were prepared. The outfitting shop handled approximately four tonnes of steel daily, but demanded proportionately more labour because of the complexity of the tasks involved. The outfitting shop consumed 50 per cent of the labour hours required to build a shipthe single greatest portion of the manual labour. While these processes were underway in the general purpose shop, machinery to be installed on board was tested and prepared for installation. A common overhead gantry crane of 5-tonnes capacity was deployed for material handling in this shop. Basic treatment and fabrication of approximately 3 tonnes of pipes and pipe spools per day were carried out in the pipe shop, according to a piping plan. A gantry crane of 5-tonnes capacity was used to move material in the pipe shop. In the sub-assembly area, panels, stiffeners, and profiles prepared in the steel shop were welded together to form sub-assemblies that measured up to 5 metres long and 2.5 metres wide, and weighed between 10 and 25 tonnes. The sub-assembly area was equipped with a gantry crane of 25-tonnes maximum capacity. Up to the sub-assembly stage, the items being processed (particularly the steel plates) were within weight and size limits that allowed the items to be moved conveniently by the material handling equipment placed within the process focused arrangement of shops in the shipyard layout. The sub-assemblies were then joined together in the panel fabrication area to form blocks up to 10x5x5 metres and weighing 20-50 tonnes. A gantry crane of 50-tonnes capacity was installed to handle these blocks. After basic outfitting and painting, the blocks were then combined in an erection area to form larger blocks of 15x10x10 metres and weighing 30-75 tonnes. At this stage, the bulky interim blocks began to take shape as the final product. The weight and dimensions of the blocks at this stage restricted their movement. Thus, from panel fabrication to dock, the shipyard layout gradually emerged as a fixed-position layout. All the items from the outfitting shop, pipe shop, and general purpose shop were transported to the block erection area to complete the pre-outfitting of the blocks. The outfitted blocks were then welded together to form super blocks of 30x15x15 metres and weighing 200 300 tonnes. These super blocks were then transferred by a Goliath crane of 600-tonnes capacity to the dock, where they were assembled to form the final complex bulky product-the ship. After erection, the ship was launched. Final outfitting and painting of the accommodation and superstructure were completed while the ship was afloat. Before final delivery of the ship, the installed machinery was tested during sea trials.? or use only in the course Logistics ManaUse outside THE WORK-IN-PROGRESS DILEMMA Pitambar had just finished reading an email from the corporate office when Sudesh, the steel shop manager, and Bidesh, the block erection manager, entered his office. Pitambar: Nice to see you Sudesh and Bidesh! You've come at just the right time. I have good news from the corporate office to share with you. Our shipyard has received a new order for five Screenshot Added A screenshot was added to your Dropbox. Dropbox 2 To visualize the shipbuilding process, see "Ship Building Process," YouTube video, 1:22, posted by "El Noras Al Bahree." May 30, 2013, accessed November 1, 2016, https://youtu.be/oGVrM191dQY. Page 4 9B16D023 Handymax 55,000 DWT bulk carriers worth US$140 million. We are to deliver them in the next two years. Sudesh: That's really great news. We can definitely do it. Bidesh: (already in a depressed mood] Given the present state of block erection area operations, I don't think we will be able to deliver this order on time. For at least the next 18 months, our block erection area is fully occupied by nearly 100 semi-finished blocks from ongoing orders. We don't have any free space to start new blocks. Pitambar: But why so many blocks at a time? And all in semi-finished state! Bidesh: [looking towards Sudesh] Because we are not getting a continuous supply of the steel plates that we require from the steel shop. yright violations from April 18, 2019 to April 08, 2022. Sudesh: But our steel shop is constantly preparing the steel plates at a high throughput. There are piles of cut profile plates stored outside our shop as WIP (work-in-progress) to be consumed by block erection activity. Pitambar [to Bidesh] Then why are you not consuming those plates and finishing the blocks? Bidesh: We have already consumed the required plates and started multiple blocks. We now need flat and curved profile plates of different thicknesses to complete these semi-finished blocks. [to Sudesh] Why don't you cut steel plates according to the block erection requirement? Pitambar: Sudesh: Because we load our CNC machines with large batches of similar thickness and profile plates. This minimizes set-up time and maximizes our KPI [key performance indicator of tonnes of steel plates processed per day. In fact, our steel shop has reported the highest KPI for the last two years continuously. Pitambar: (after thinking for some time] Okay. Now, I understand the root cause of your WIP problem. Since you are focusing on your respective KPIs, a typical trait demonstrated by process- focused shops, you lose track of the overall goal of completing the entire ship. On the one hand, this approach increases the throughput of the steel shop for plates of one particular thickness. On the other hand, it means that plates of other thicknesses are not available, although these are required for the completion of ongoing blocks. This forces the block erection team to halt production of blocks in a semi-finished state and start on new blocks for which plates are available. As a result, the entire block erection area fills up with semi- finished blocks and eventually the block erection team runs out of space to start further blocks. This reduces the consumption rate of available steel plates and leads to a higher WIP. This vicious circle continues and impacts the overall performance of the project. You have to facilitate communication and information sharing with each other so that the steel shop cuts only those plates that are actually required for block erection. This will resolve the WIP problem by establishing congruence between the output of the steel shop and the input requirements of the block erection area. All eurrency amounte are in US$ unleee otherwiee epecified. Page 5 9B16D023 Bidesh: That's a good solution. It will help us to finish the interim product as a complete block before starting a new block. Sudesh: But I foresee a challenge to establishing this congruence between output and input (from the steel shop to block erection). To suit the varying demands of block erection, the steel shop will have to set up its machines more often. This will have a negative impact on our KPI. So, why should we sacrifice our KPI to benefit block erection? To ensure long-term solution, the arrangement should be mutually beneficial. The Theory of Constraints Pitambar: yright violation, as from April 08, 2019 to April 08,2022. Let me explain this from a theory of constraints perspective. In a relationship, the two entities should understand each other's strengths and weaknesses. If we analyze the production process closely, we will realize that initial stages of production like steel preparation, steel cutting, and sub-assembly are very similar for all types of ships. The strength of the steel shop is that its processes are mostly repetitive; thus, it has an opportunity to benefit from economies of scale. However, at the block erection stage, there is a clear differentiation based on ship type. The complexity of the tasks involved and the necessary skill level increase as the assembly of blocks commences. On top of this, construction of super blocks and the final ship require spatial resources like a block erection area, a heavy capacity Goliath crane, and a dockall fixed in position. The block erection area and the dock limit the throughput of the shipyard. We cannot increase the capacity of these constrained resources in the short term as they are very costly options. According to the theory of constraints, the identified constrained resource should be fully utilized and every other decision should be subordinated to it. In our production system, the block erection area is the constrained resource. So, ensure its maximum utilization, decisions regarding output of its predecessorthe steel shop-should be governed by the input requirements of the constrained resource. Product-Focused Layout of the Steel Shop Pitambar: I have a solution to decrease the number of set-ups needed in the steel shop, while still satisfying the block erection requirements. The steel shop performs the maximum number of set-ups when it changes product from flat plates to curved plates. So, if we can identify and group dedicated machines in the steel shop according to product families, we'll have two cells: a flat-block line and a curved-block line. Then we can orient the layout by product and get a linear flow of material. This would minimize material movement and reduce the number of set-ups. For use cnly in th Sudesh: So, inside the broad process focused layout of our shipyard, we will have semi-self-contained work cellsa product-focused layout inside a process focused steel shop. This is interesting! But again there is a problem. To configure these cells, machinery has to be shifted, and this will stall daily production activities. This is not possible now because production of two ships is underway at our yard. Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 5 9B16D023 Bidesh: That's a good solution. It will help us to finish the interim product as a complete block before starting a new block. Sudesh: But I foresee a challenge to establishing this congruence between output and input (from the steel shop to block erection). To suit the varying demands of block erection, the steel shop will have to set up its machines more often. This will have a negative impact on our KPI. So, why should we sacrifice our KPI to benefit block erection? To ensure long-term solution, the arrangement should be mutually beneficial. The Theory of Constraints Pitambar: yright violation, as from April 08, 2019 to April 08,2022. Let me explain this from a theory of constraints perspective. In a relationship, the two entities should understand each other's strengths and weaknesses. If we analyze the production process closely, we will realize that initial stages of production like steel preparation, steel cutting, and sub-assembly are very similar for all types of ships. The strength of the steel shop is that its processes are mostly repetitive; thus, it has an opportunity to benefit from economies of scale. However, at the block erection stage, there is a clear differentiation based on ship type. The complexity of the tasks involved and the necessary skill level increase as the assembly of blocks commences. On top of this, construction of super blocks and the final ship require spatial resources like a block erection area, a heavy capacity Goliath crane, and a dockall fixed in position. The block erection area and the dock limit the throughput of the shipyard. We cannot increase the capacity of these constrained resources in the short term as they are very costly options. According to the theory of constraints, the identified constrained resource should be fully utilized and every other decision should be subordinated to it. In our production system, the block erection area is the constrained resource. So, ensure its maximum utilization, decisions regarding output of its predecessorthe steel shop-should be governed by the input requirements of the constrained resource. Product-Focused Layout of the Steel Shop Pitambar: I have a solution to decrease the number of set-ups needed in the steel shop, while still satisfying the block erection requirements. The steel shop performs the maximum number of set-ups when it changes product from flat plates to curved plates. So, if we can identify and group dedicated machines in the steel shop according to product families, we'll have two cells: a flat-block line and a curved-block line. Then we can orient the layout by product and get a linear flow of material. This would minimize material movement and reduce the number of set-ups. For use cnly in th Sudesh: So, inside the broad process focused layout of our shipyard, we will have semi-self-contained work cellsa product-focused layout inside a process focused steel shop. This is interesting! But again there is a problem. To configure these cells, machinery has to be shifted, and this will stall daily production activities. This is not possible now because production of two ships is underway at our yard. Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 6 9B16D023 Adoption of Virtual Cells in the Short Term Pitambar: I suggest we adopt the virtual cell concept to temporarily resolve this problem. In this approach, we do not physically shift resources; instead, we virtually group resources. In the short term, this will enable us to derive incremental benefits from cellular manufacturing. In the long term, we can incorporate shut-downs in our production planning schedule to gradually reconfigure the steel shop. Sudesh: Okay, the virtual cells suggestion with the theory of constraints justification seems logical to resolve the WIP problem. This might establish a mutually beneficial relationship between the two departments. April 08, 2019 to April 08, 2022. Revision of the Shipyard Layout Bidesh: On similar lines, if we compare our existing shipyard layout with the required inter-shop proximity based on the shipbuilding process, I see potential for improving the positioning of process-focused shops relative to each other. For example, most of the steel plates from the steel shop go to the paint shop, so proximity between those two shops should be especially important. But in our existing layout, they are located far apart. Similarly, most pipe spools are consumed as pre-outfitting at the sub- assembly stage. So, the pipe shop and the sub-assembly area can be brought closer. In the exist the warehous is adjacent to the office and supporting activities area, which is not necessary. Instead, the warehouse can be moved closer to the general purpose and outfitting shops. Pitambar: Yes, this is a good suggestion. At present, we have unnecessarily convoluted movement of material across the yard. We have to devise a scientific approach that can tell us how much our existing layout deviates from what's required by the shipbuilding process and how much closer we can get to the ideal linear flow of material. For use only in the course Logistics ManagUse outside these parameters is a copyright violation Eventually, an improved layout will lead to better material flow, reduce shipbuilding cycle time, increase throughput, and prepare us to handle the increasing order book in the current booming shipbuilding market. But this will require relocation of shops and considerable investments. IS IT POSSIBLE? After their conversation with Pitambar, Sudesh, and Bidesh left for their daily commitments. Pitambar remained seated at his desk contemplating whether the new order of five Handymax 55,000 DWT naval bulk carriers should be accepted. Could the shipyard complete the order in two years? Would revising the shipyard layout enable the shipyard to deliver the order? If so, how could they scientifically justify the major revision so that top management approved the investment? Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 7 9B16D023 EXHIBIT 1: BLOCKS OF A SHIP Flat Blocks Midship Midship Block 1 Midship Block 3 Curved Block 2 Curved Fore Block Aft Block Source: Created by the authors using company documents e outside these parameters is a copyright violatidessors from April 08, 2019 to April 08, 2022. EXHIBIT 2: EXISTING LAYOUT OF THE ABC SHIPYARD Design Orlice General Purpose Shop Pipe Shop Paint Shop Outfitting Shop 5 T Gantry Crane Supporting Activities Area 5 T Gantry Crane Medical Centre Steel Shop 600 T Goliath Crane Block Erection Quay 10 T Gantry Crane 25 T Gant Steel Stockyard 1 Panel Fabrication Area 50 T Gantry Crane Nole: Not to scale; arrows show only main material flow. Source: Created by the authors using company documents. For use only in Screenshot Added A screenshot was added to your Dropbox. Dropbox Page 8 9B16D023 EXHIBIT 3: FLOW CHART OF THE SHIPBUILDING PROCESS Steel from stockyard Steel preparation, cutting, and plate bending at steel shop Priming and painting m April 08, 2019 to April 08, 2022. Panel fabrication and sub-assembly of flat and curved blocks Assembly of flat and curved blocks Pipe spool preparation at pipe shop Assembly of super blocks at block erection area Machinery preparation at general purpose shop Outfitting preparations at outfitting shop Super block assembly at dock Launching quay Commissioning Delivery For use only in the course Logistics Manag Use outside these parameters is a copyright violation Source: Created by the authors from company documents. Screenshot Added A screenshot was added to your Dropbox. Dropbox