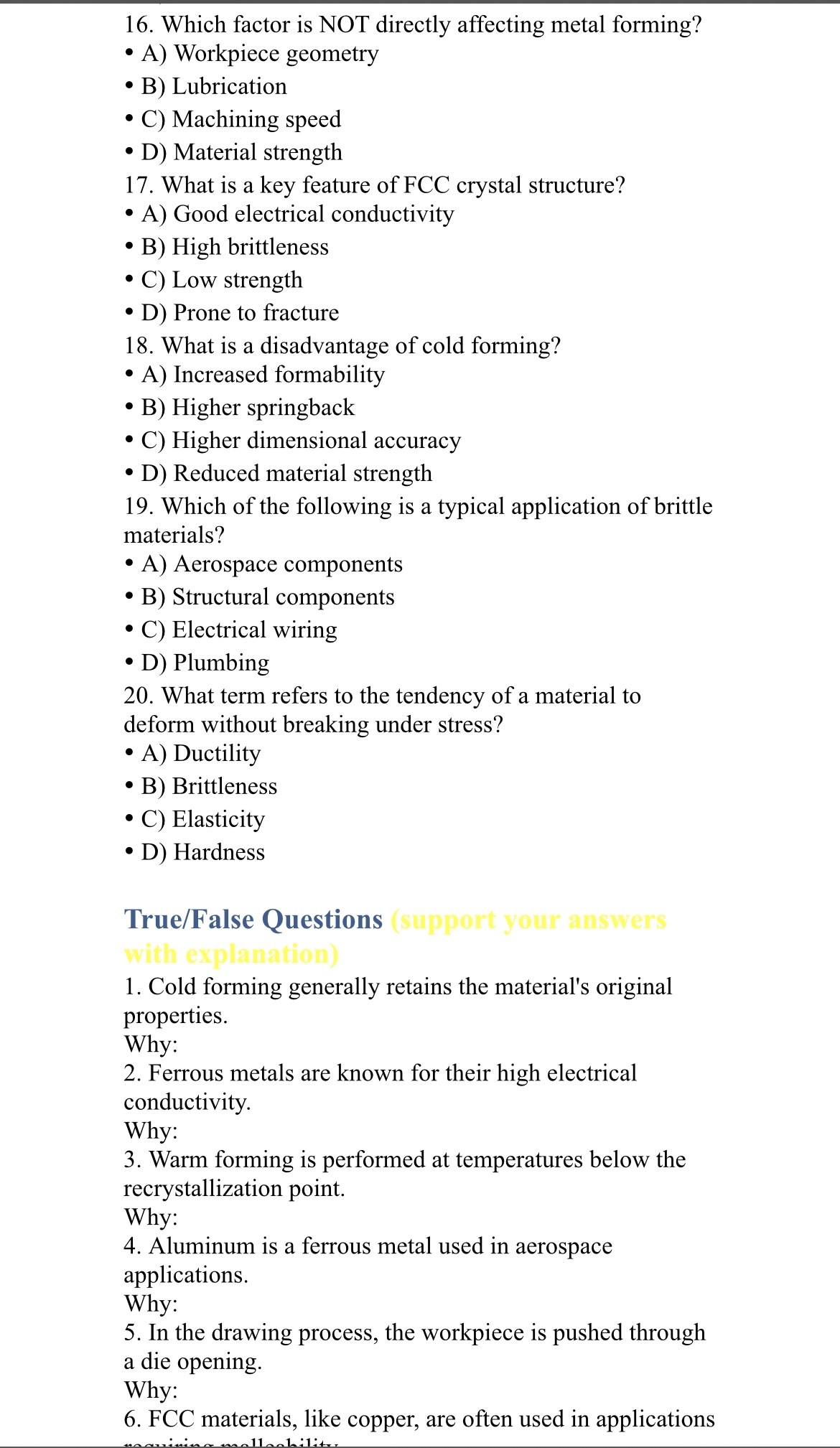

Question: Which factor is NOT directly affecting metal forming? A ) Workpiece geometry B ) Lubrication C ) Machining speed D ) Material strength What is

Which factor is NOT directly affecting metal forming?

A Workpiece geometry

B Lubrication

C Machining speed

D Material strength

What is a key feature of FCC crystal structure?

A Good electrical conductivity

B High brittleness

C Low strength

D Prone to fracture

What is a disadvantage of cold forming?

A Increased formability

B Higher springback

C Higher dimensional accuracy

D Reduced material strength

Which of the following is a typical application of brittle

materials?

A Aerospace components

B Structural components

C Electrical wiring

D Plumbing

What term refers to the tendency of a material to

deform without breaking under stress?

A Ductility

B Brittleness

C Elasticity

D Hardness

TrueFalse Questions

Cold forming generally retains the material's original

properties.

Why:

Ferrous metals are known for their high electrical

conductivity.

Why:

Warm forming is performed at temperatures below the

recrystallization point.

Why:

Aluminum is a ferrous metal used in aerospace

applications.

Why:

In the drawing process, the workpiece is pushed through

a die opening.

Why:

FCC materials, like copper, are often used in applications

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock