Question: will give good ratings give clear answer D. Exercises Ex1 Direct, Indirect, Fixed and Variable Costs Sheger Bread Factory Manufactures Flout 125 to 1000 bread

will give good ratings

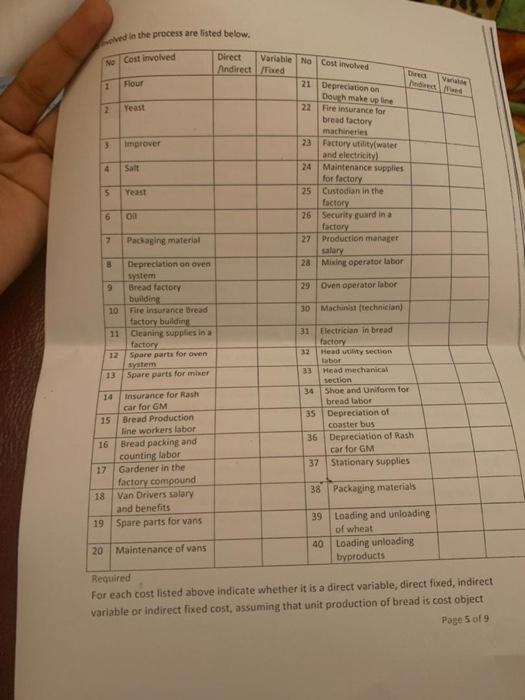

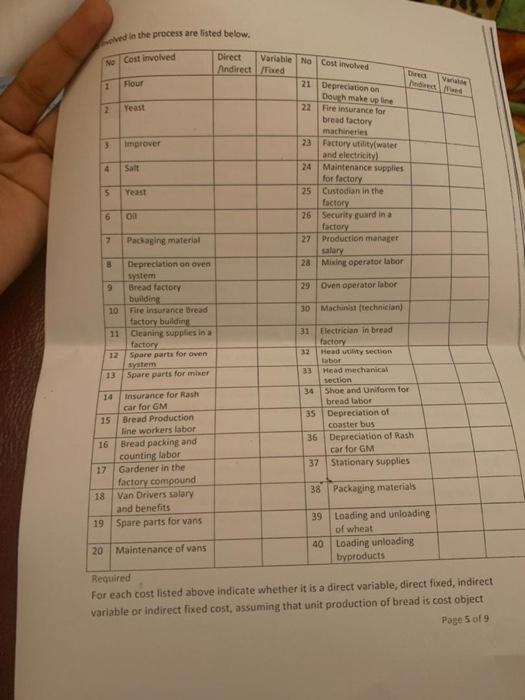

D. Exercises Ex1 Direct, Indirect, Fixed and Variable Costs Sheger Bread Factory Manufactures Flout 125 to 1000 bread to be distributed to 400 enterprises (382 Addis Ababa city and 8 nearby cities buraya Sebeta and Legetafo). Bread production in Sheger Bread Factory requires a six step process 1. The First step is mixing. The mixing unit combines all of the ingredients to create the dough and processes it through high speed mixers (90 RPM. 2. The second step is dough make u, which is entirely automated process that shapes the dough and cut the dough into pieces as per preset dough weight for a loaf of bread (currently set at 92e) 3. The third step is trolley loading process. This process is also automatic, the system loads a trolley of carrying capacity of 16 plates that holds 40 loaf of bread and 40 X 60 = 640 loaf of bread 4. The fourth step is steaming process (proofing). This is a fermentation process. A trolley fully loaded by trolley loading system is taken by labor to steam house for fermentation. (Bread dough is left to rise in the steam house for 40 to 60 minutes for complete fermentation) 5. The fifth step is baking process. This step is also fully automatic after oven feeders feed bread fermented dough from the trolley to oven belt of the oven system. The oven system feeds fermented bread dough to the oven, bakes in a high temperature about 240 loaf of bread per each compartment (2 ovens in a singly oven system and 12 compartments in a single oven system 6 per each oven). The factory plant has 6 oven system -six pairs of ovens 6. The final step is cooling and packaging process. This final step is entirely manual process. The labor force in this unit allows loaf of bread to cool and then carefully package 100 loaf of bread in a create and store in satellite store. ved in the process are listed below. NO Cost involved Variable No Cost involved Direct Indirect Fored Flour 1 Nu 2 Yeast 3 Improver 21 Depreciation on Douch make up line 22 Fire Insurance for bread factory machineries 23 Factory utility(water and electricity) 24 Maintenance supplies for factory 25 Custodian in the factory 26 Security guard in a factory 27 Production manager 4 Salt 5 Yeast 6 ON 7 Packaging material salary B Depreciation on oven 28 Mixing operator labor syatem Bread factory 29 Oven operator labor building 10 Fire Insurance Bread 30 Machinist (technician factory building Cleaning supplies in a 31 Electrician in bread factory factory 12 Spare parts for oven 32 Heady section syatem Labo Spare parts for mixer Head mechanical section 14 Insurance for Rash Shoe and Uniform for car for GM bread tabor 15 Bread Production 35 Depreciation of line workers labor coaster bus 16 Bread packing and 36 Depreciation of Rash counting labor car for GM 17 Gardener in the 37 Stationary supplies factory compound 18 Van Drivers salary 38 Packaging materials and benefits 19 Spare parts for vans 39 Loading and unloading of wheat 20 Maintenance of vans 40 Loading unloading byproducts Required For each cost listed above indicate whether it is a direct variable, direct fixed, indirect variable or indirect fixed cost, assuming that unit production of bread is cost object Page 5 of 9 give clear answer

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock