Question: With the case study above create: 1a.Project Charter 1b.Stakeholder Register 1c.Stakeholder Engagement Plan Ready the case study in picture and create the the following 1a.

With the case study above create:

1a.Project Charter

1b.Stakeholder Register

1c.Stakeholder Engagement Plan

Ready the case study in picture and create the the following

1a. Project Charter

1b. Stakeholder Register

1c. Stakeholder Engagement Plan

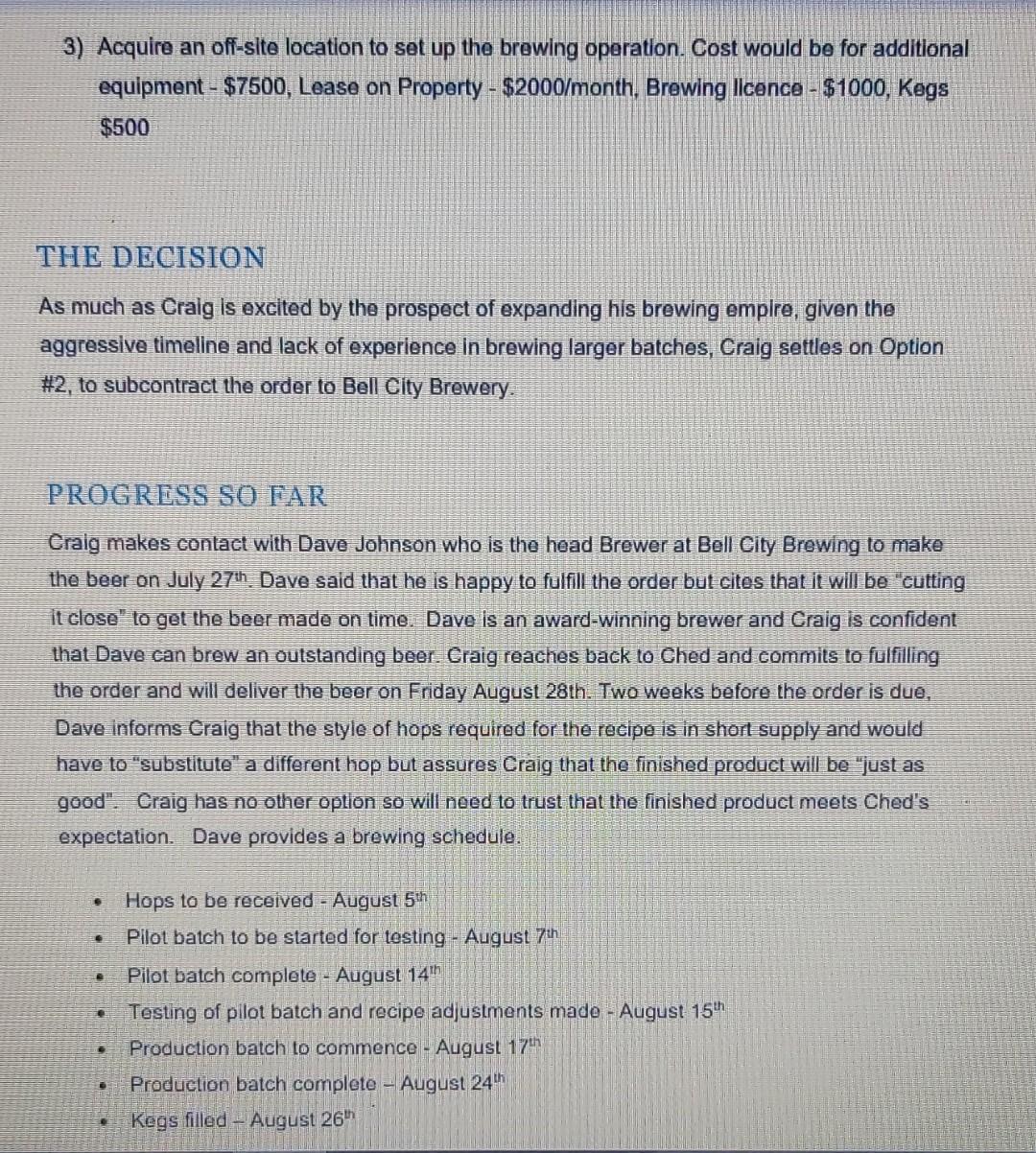

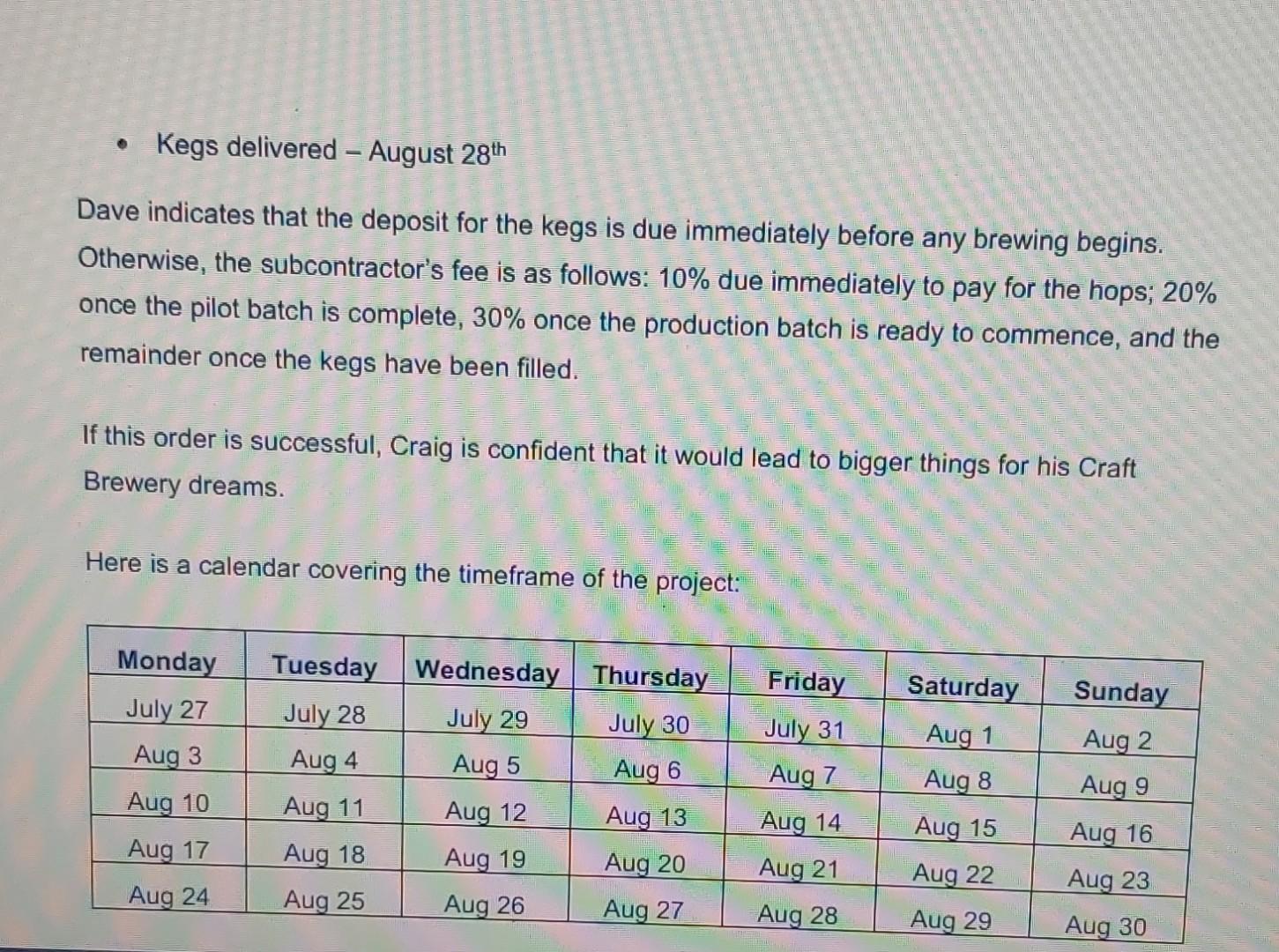

Professor Kerr (Craig) needs your help. Craig is a craft beer enthusiast and has a home brewing system in his garage. The home brewing system can brew a maximum of 50 litres (100 pints of beer) per week. The cost of a 50 litres of beer is $100. This includes the malted barley, yeast, hops, and water. Recently Craig entered one of his brewing creations in a craft beer contest and much to his surprise won the contest. The Contest organizer Ched Anderson liked the beer so much that he asked Craig if he could contract him to brew a larger batch of the beer for his establishment. Ched is very influential in the craft beer community. Ched needs 10 kegs of beer for his upcoming Beerfest celebration on Saturday August 29th. That is 500 litres of beer. Ched is willing to pay $5/litre. Craig is excited about the opportunity but as it stands it takes him two weeks to brew 50 litres of beer. THE OPTIONS Craig sits down with his wife Jenny to discuss the business proposition. Jenny reluctantly supports Craig's hobby but is less than happy with the smell of the garage when Craig is brewing beer. But Jenny likes the fact that the remnant "mash" is donated to local farms for feed. Craig mulls around options in his head on how he can meet the deadline for delivery and comes up with three options: 1) Add additional equipment to the garage to increase brewing capacity. The cost of the equipment would be $5000, and Brewing Licence - $1000, Kegs - $500 2) Subcontract the brewing to a local brewer with available capacity, Bell City Brewery. The Subcontractor's fee will cost 40% more than brewing at home plus a deposit of $50/keg. 3) Acquire an off-site location to set up the brewing operation. Cost would be for additional equipment - $7500, Lease on Property - $2000/month, Brewing Ilcence - $1000, Kegs $500 THE DECISION As much as Craig is excited by the prospect of expanding his brewing empire, given the aggressive timeline and lack of experience in brewing larger batches, Craig settles on Option \#2, to subcontract the order to Bell City Brewery. PROGRESS SO FAR Craig makes contact with Dave Johnson who is the head Brewer at Bell City Brewing to make the beer on July 277. Dave said that he is happy to fulfill the order but cites that it will be "cutting it close" to get the beer made on time. Dave is an award-winning brewer and Craig is confident that Dave can brew an outstanding beer. Craig reaches back to Ched and commits to fulfilling the order and will deliver the beer on Friday August 28 th. Two weeks before the order is due, Dave informs Craig that the style of hops required for the recipe is in short supply and would have to "substitute" a different hop but assures Craig that the finished product will be "just as good". Craig has no other option so will need to trust that the finished product meets Ched's expectation. Dave provides a brewing schedule. - Hops to be received - August 5th - Pilot batch to be started for testing - August 7th - Pilot batch complete - August 14m - Testing of pilot batch and recipe adjustments made - August 15th - Production batch to commence - August 17th Production batch complete - August 24th Keas filled - August 26th - Kegs delivered - August 28th Dave indicates that the deposit for the kegs is due immediately before any brewing begins. Otherwise, the subcontractor's fee is as follows: 10% due immediately to pay for the hops; 20% once the pilot batch is complete, 30% once the production batch is ready to commence, and the remainder once the kegs have been filled. If this order is successful, Craig is confident that it would lead to bigger things for his Craft Brewery dreams. Here is a calendar covering the timeframe of the project

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts