Question: work system I need answer asap. There are three workers in a machine shop where any one of them can operate up to three machines.

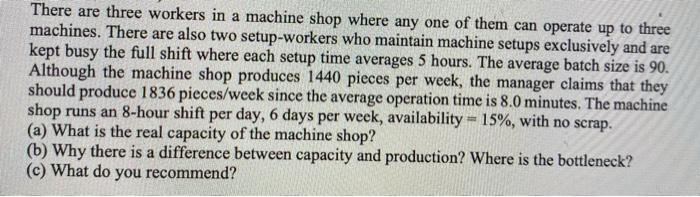

There are three workers in a machine shop where any one of them can operate up to three machines. There are also two setup-workers who maintain machine setups exclusively and are kept busy the full shift where each setup time averages 5 hours. The average batch size is 90. Although the machine shop produces 1440 pieces per week, the manager claims that they should produce 1836 pieces/week since the average operation time is 8.0 minutes. The machine shop runs an 8-hour shift per day, 6 days per week, availability = 15%, with no scrap. (a) What is the real capacity of the machine shop? (b) Why there is a difference between capacity and production? Where is the bottleneck? (c) What do you recommend? There are three workers in a machine shop where any one of them can operate up to three machines. There are also two setup-workers who maintain machine setups exclusively and are kept busy the full shift where each setup time averages 5 hours. The average batch size is 90. Although the machine shop produces 1440 pieces per week, the manager claims that they should produce 1836 pieces/week since the average operation time is 8.0 minutes. The machine shop runs an 8-hour shift per day, 6 days per week, availability = 15%, with no scrap. (a) What is the real capacity of the machine shop? (b) Why there is a difference between capacity and production? Where is the bottleneck? (c) What do you recommend

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts