Question: Worker 1 : Tasks 1 , 2 Worker 2 : Tasks 3 , 4 , 5 Worker 3 : Tasks 6 , 7 , 8

Worker : Tasks Worker : Tasks Worker : Tasks

What is the capacity of the current line?

What are the direct labor content and the average labor utilization?

How long does it take to produce units, starting with an empty system?

For parts and assume that the firm hires a fourth worker and the tasks are allocated to four

workers to maximize the capacity.

What is the maximum capacity that can be achieved if i the tasks are not divisible, ii a worker

can only perform adjacent tasks and iii all tasks need to be done in numerical order?

What is the maximum capacity that can be achieved if the tasks are perfectly divisible? How does

the worker utilizations change compared to part why?

For parts and assume that the firm combines all the tasks in a workcell where a single worker

performs all the tasks. In this case,

What is the capacity of the system with a single worker and what is the worker utilization?

What is the minimum number of workers ie workcells needed to achieve a capacity of

unitshourThe current workerpaced bottleneck paced assembly line configuration assigns the workers in the

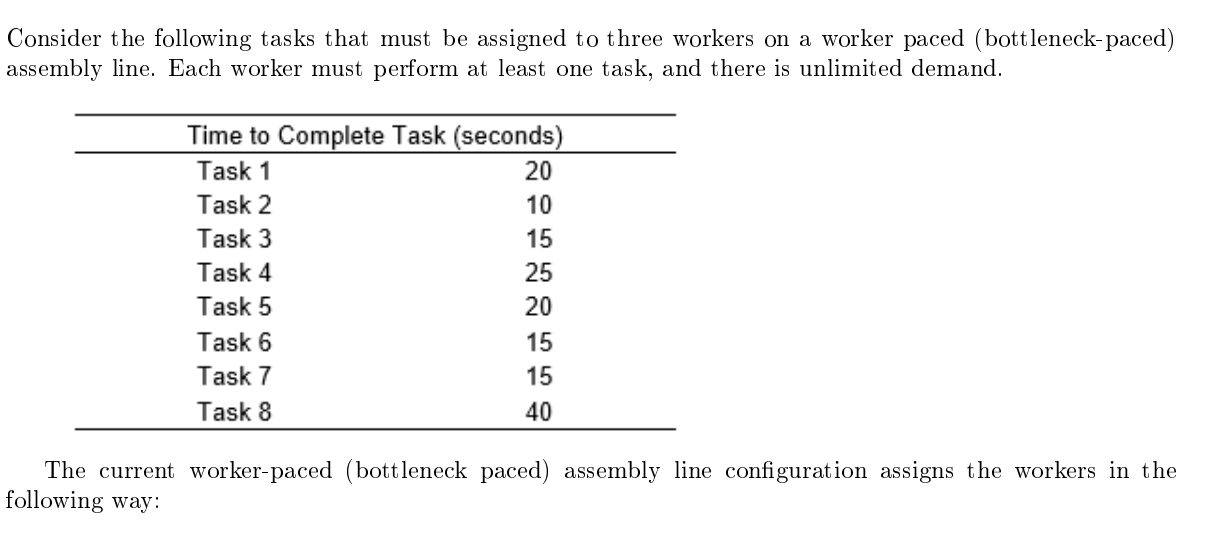

following way:Consider the following tasks that must be assigned to three workers on a worker paced bottleneckpaced

assembly line. Each worker must perform at least one task, and there is unlimited demand.

The current workerpaced bottleneck paced assembly line configuration assigns the workers in the

following way:

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock