Question: Write more than 1100 words Step 1: Problem Definition There may be more than one key issue in the case . Determine the issues or

Write more than 1100 words

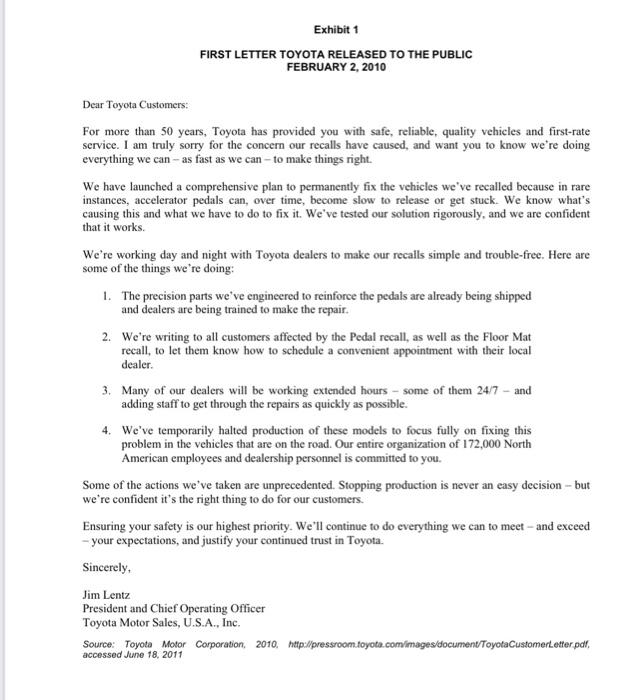

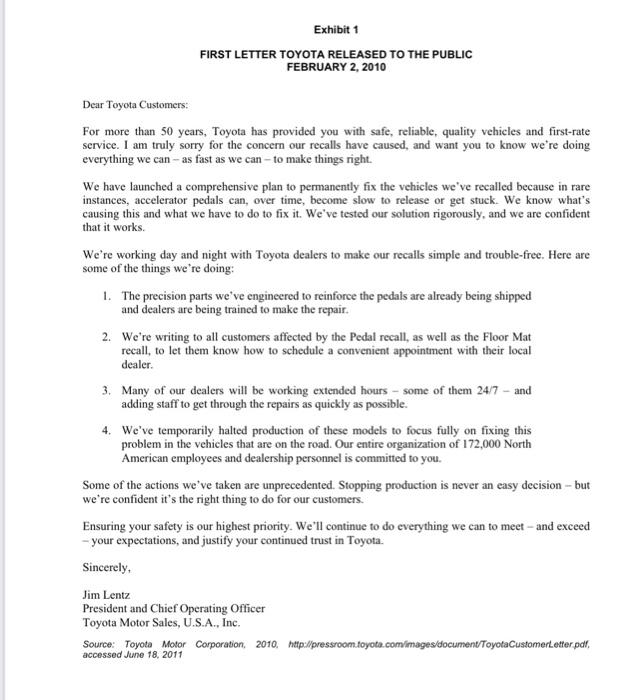

TOYOTA: ACCELERATOR PEDAL RECALL (A)" Paul Bigus wrote this case under the supervision of Professor Jana Sejts solely to provide material for class discussion. The authors do not intend to llustrate either effective or ineffective handling of a managerial situation. The authors may have disguised certain names and other identifying information to protect confidentiality Richard Ivey School of Business Foundation prohibits any form of reproduction, storage or transmission without its written permission. Reproduction of this material is not covered under authorization by any reproduction rights organization. To order copies or request permission to reproduce materials, contact Ivey Publishing. Richard Ivey School of Business Foundation, The University of Western Ontario, London, Ontario, Canada, N6A 3K7: phone (519) 661-3208; fax (519) 661-3882, e-mail cases@ivey.wo.ca. Copyright 2011, Richard Ivey School of Business Foundation Version: 2011-12-08 On Tuesday, February 2, 2010, Jim Lentz, president of Toyota Motor Sales, U.S.A. Inc. (Toyota), released a letter to the public in response to a large-scale recall of Toyota vehicles with faulty accelerator pedals. Unfortunately, the letter caused outrage among consumers, business analysts and government officials. Toyota had also received negative feedback from the media, with headlines such as "Toyota drops the ball with customer safety." "Toyota's response criticized" and "Toyota consumers still looking for answers." In view of Toyota's plan to draft a second letter for release within the next week, it was critical to understand what had gone wrong with the content of the first letter in order to better communicate the correct message to the public regarding Toyota's efforts to address the accelerator-recall situation. COMPANY HISTORY Global automotive manufacturer Toyota started in Japan with the actions of Sakichi Toyoda and his company, Toyoda Automatic Loom Works, Ltd. (TALW). In 1924, Toyoda successfully established himself in the world of business by creating the first automatic loom used for fabric manufacturing in the textile industry. The debut of this piece of equipment was seen as a major advancement in production and productivity, not only in Japan but around the world. In 1929, Kiichiro Toyoda, the son of Sakichi Toyoda, travelled to the United States and Europe, with an interest in researching automobiles. When he returned to Japan in 1930 to conduct research into gasoline-powered engines, his work led to the establishment of an automobile department within TALW. A few years later, in 1935, Kiichiro Toyoda succeeded in creating the Al prototype passenger car. Automotive history was made in 1937, when the automotive department at TALW separated from the rest of the company and established itself as Toyota Motor Co. Ltd. (Toyota). Shortly thereafter, This case has been written on the basis of published source only. Consequently, the interpretation and perspectives presented in this case are not necessarily those of the Toyota Motor Corporation or any of its employees Toyota Motor Corporation 2011. History of Toyota http://www.toyota-global.com/company history_of_toyota/, accessed June 18, 2011 manufacturing of the first car and truck models began, quickly reaching domestic production of 100,000 vehicles by 1947. Toyota entered the international market in 1957 by establishing Toyota Motor Sales U.S.A. Inc. and exporting the first Japanese passenger car ("the Crown") to the United States. Rapid growth in the automotive industry continued, with Toyota producing its one millionth vehicle in 1962. Innovations in manufacturing, such as "Just In Time" and "Total Quality Control," led to key industry advantages in production. In 1984. Toyota started production for the first time in the United States in a joint venture with General Motors, later opening an independent Toyota plant in Kentucky in 1988. In the 1990s, Toyota's 100 millionth vehicle was produced domestically, with annual overseas sales exceeding three million units and still growing. As of 2009, Toyota recorded worldwide sales over US$195,000 million, selling 7.2 million vehicles worldwide. In a market once dominated by U.S. automakers General Motors, Ford and Chrysler, Toyota had established itself as the world's largest automotive manufacturer, employing over 300,000 people and operating 53 production facilities in 26 countries around the globe. Aggressive growth was planned to continue into the emerging automotive markets in China and India, along with the development and sales of new products such as plug-in, hybrid vehicles. As an organization, Toyota Motor Company Ltd. operated as part of the larger Toyota Industries Corporation, which involved activities in automotive, material handling, logistics, electronics and textile machinery THE FAULTY ACCELERATOR PEDAL RECALL Toyota's difficulties had actually started a month earlier on January 21, 2010, when the company had publically announced a large-scale recall, involving cigit different models and totaling 2.3 million vehicles in the United States and an estimated nine million worldwide, due to a faulty accelerator pedal. In certain instances, a defect caused vehicle accelerator pedals to stick, resulting in unintended acceleration. Toyota had already been reeling publically due to a previous vehicle recall in August 2009, in which a total of 4.2 million vehicles had been recalled due to faulty driver-side floor mats, which in some instances could trap the accelerator pedal to the vehicle floor (much like the current situation), causing unintended and dangerous acceleration THE FIRST LETTER In order to communicate the current massive vehicle recall, Toyota drafted an official letter that was posted on the company website and sent out to Toyota customers, it was also featured in major newspaper publications. On February 2, 2010, the letter was released, but it was quickly criticized by the media and consumers alike (see Exhibit 1). In light of all the negative feedback, Lentz started to make a list, identifying all the problems in the first letter. In terms of purpose and audience perspective, it was important to not make the same mistakes when drafting the second letter Toyota Motor Corporation. 2010, Investor Fact Sheet http://www.toyota.com/about/our_business investor_relations/ Factsheet_FY10.pdf, accessed June 18, 2011 Exhibit 1 FIRST LETTER TOYOTA RELEASED TO THE PUBLIC FEBRUARY 2, 2010 Dear Toyota Customers: For more than 50 years, Toyota has provided you with safe, reliable, quality vehicles and first-rate service. I am truly sorry for the concern our recalls have caused, and want you to know we're doing everything we can - as fast as we can to make things right. We have launched a comprehensive plan to permanently fix the vehicles we've recalled because in rare instances, accelerator pedals can, over time, become slow to release or get stuck. We know what's causing this and what we have to do to fix it. We've tested our solution rigorously, and we are confident that it works. We're working day and night with Toyota dealers to make our recalls simple and trouble-free. Here are some of the things we're doing: 1. The precision parts we've engineered to reinforce the pedals are already being shipped and dealers are being trained to make the repair. 2. We're writing to all customers affected by the Pedal recall, as well as the Floor Mat recall, to let them know how to schedule a convenient appointment with their local dealer. 3. Many of our dealers will be working extended hours - some of them 24/7 - and adding staff to get through the repairs as quickly as possible. 4. We've temporarily halted production of these models to focus fully on fixing this problem in the vehicles that are on the road. Our entire organization of 172,000 North American employees and dealership personnel is committed to you. Some of the actions we've taken are unprecedented. Stopping production is never an easy decision - but we're confident it's the right thing to do for our customers. Ensuring your safety is our highest priority. We'll continue to do everything we can to meet - and exceed - your expectations, and justify your continued trust in Toyota Sincerely, Jim Lentz President and Chief Operating Officer Toyota Motor Sales, U.S.A., Inc. Source: Toyota Motor Corporation, 2010. http://pressroom toyota.com/images/document/ToyotaCustomer etter pdf, accessed June 18, 2011 Step 1: Problem Definition There may be more than one key issue in the case . Determine the issues or symptoms that need to be most immediately addressed. Consider the causes of these issues Be sure to differentiate between immediate problems and more basic issues. For example, an immediate problem in another case scenario could be high employee absenteeism, but the more basic issue may be low employee morale or lack of motivation . How you define a problem determines how you will resolve it. For example , a short-term solution for absenteeism would differ from solutions to improve morale or motivation . Identify both the symptom and the underlying cause . Also bear in mind that this course is about communications, so focusing on technical issues is likely not the main goal of analyzing this case.

Step 2: Summary of the Facts / Justification for Problem Definition Summarize key information from the case that relates to your stated problem. You may need to make some assumptions . Identify your assumptions and state key facts. Any assumptions made should be based on your knowledge of typical managerial practices and should be consistent with the facts about the case. Management decisions are often based on limited information.

Step 3List Alternative Courses of Action Brainstorm ideas that may solve your stated problem. List as many as you can without evaluating them. You can always cross them out later. The point is to let your imagination take over . Include 5 or 6 in your list.

Step 4: Evaluate Alternatives Evaluate each of the alternatives generated in Step 3. What are the advantages and disadvantages of each alternative in terms of solving your stated problem? Or, can you use some other tool for evaluating, such as a SWOT analysis? Determine the most appropriate method for evaluating, given the nature of the case and the stated problem .

Step 5: Review (This is not part of your written paper ! It is part of your writing process) Reread your notes and consider your ideas. You may want to set your case aside overnight and "sleep on it." Come back to it later after you have considered your work .

Step 6: Make Recommendations and Conclusions Based on your evaluation in step 4, choose the alternative(s) you would recommend and explain why this is the best solution. Explain how you will implement your recommendation (s) in an action plan that states who should do what, when, and how .

Step 7: Follow Up and Evaluate Of course, you cannot actually implement your recommendations in this classroom setting and evaluate their impact . But, in this step, explain how you would evaluate the success of your implementation . Include a schedule and methods for evaluating the outcome. Indicate who will be responsible for the evaluation.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock