Question: WZ's operations manager has explained his problem and asked you to develop the best solution to help him in planning his Production Process, forecasting the

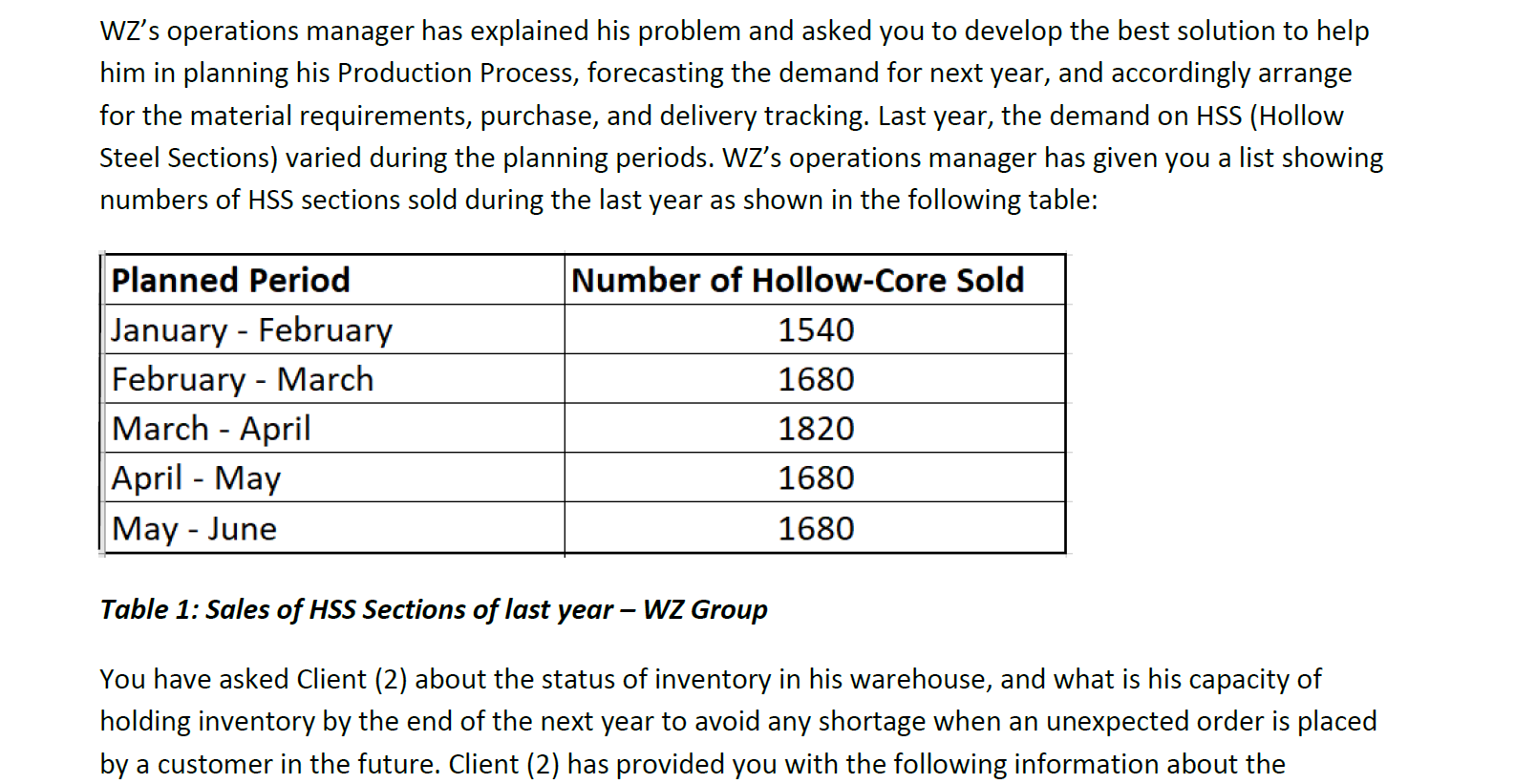

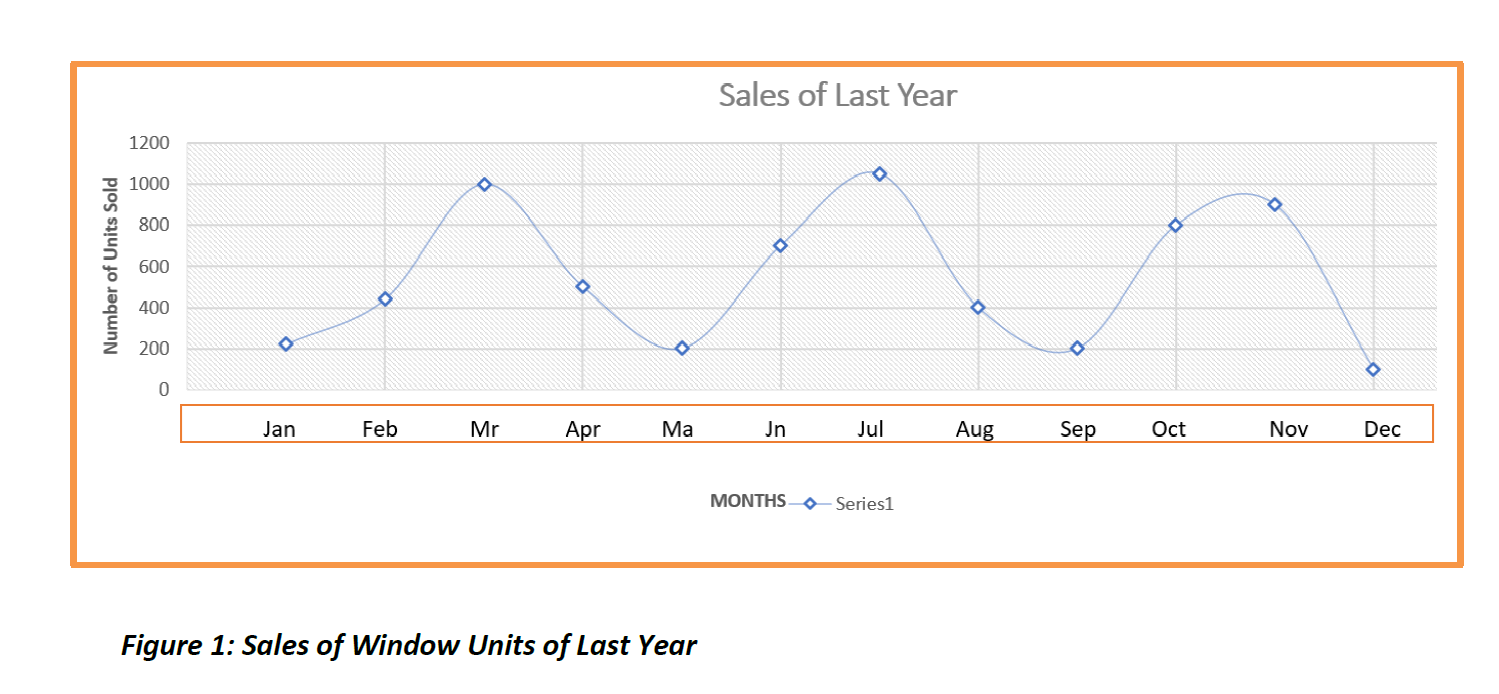

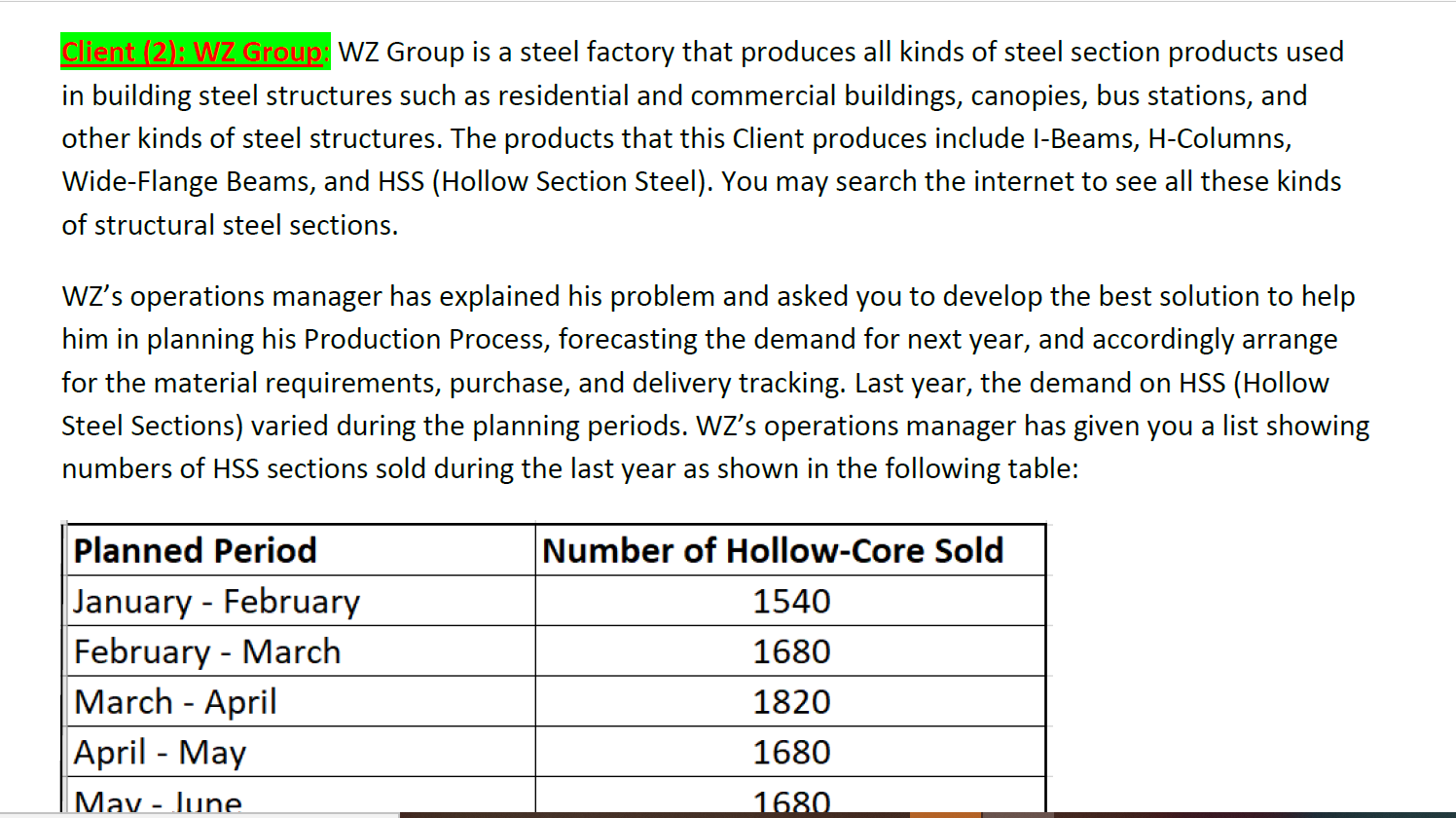

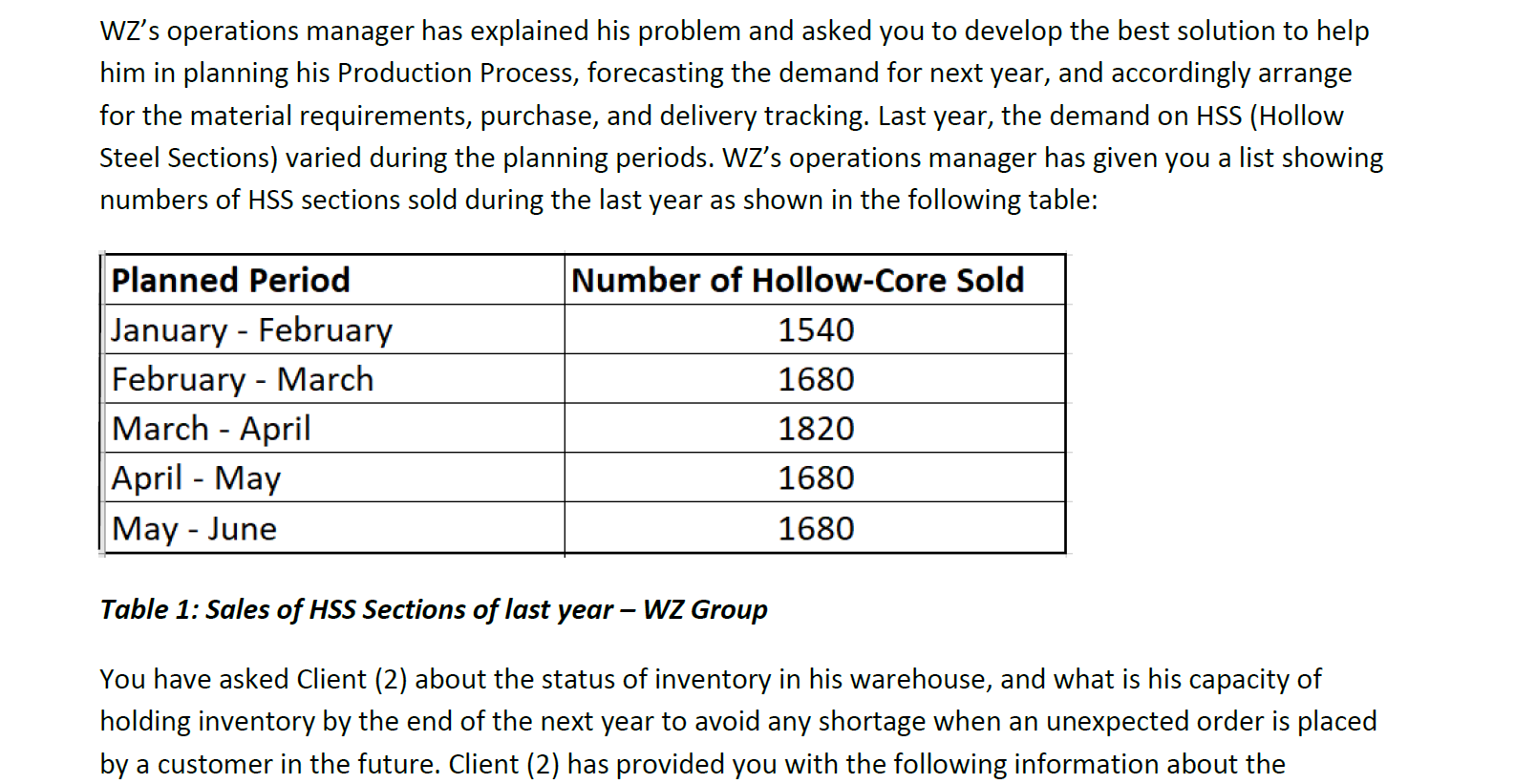

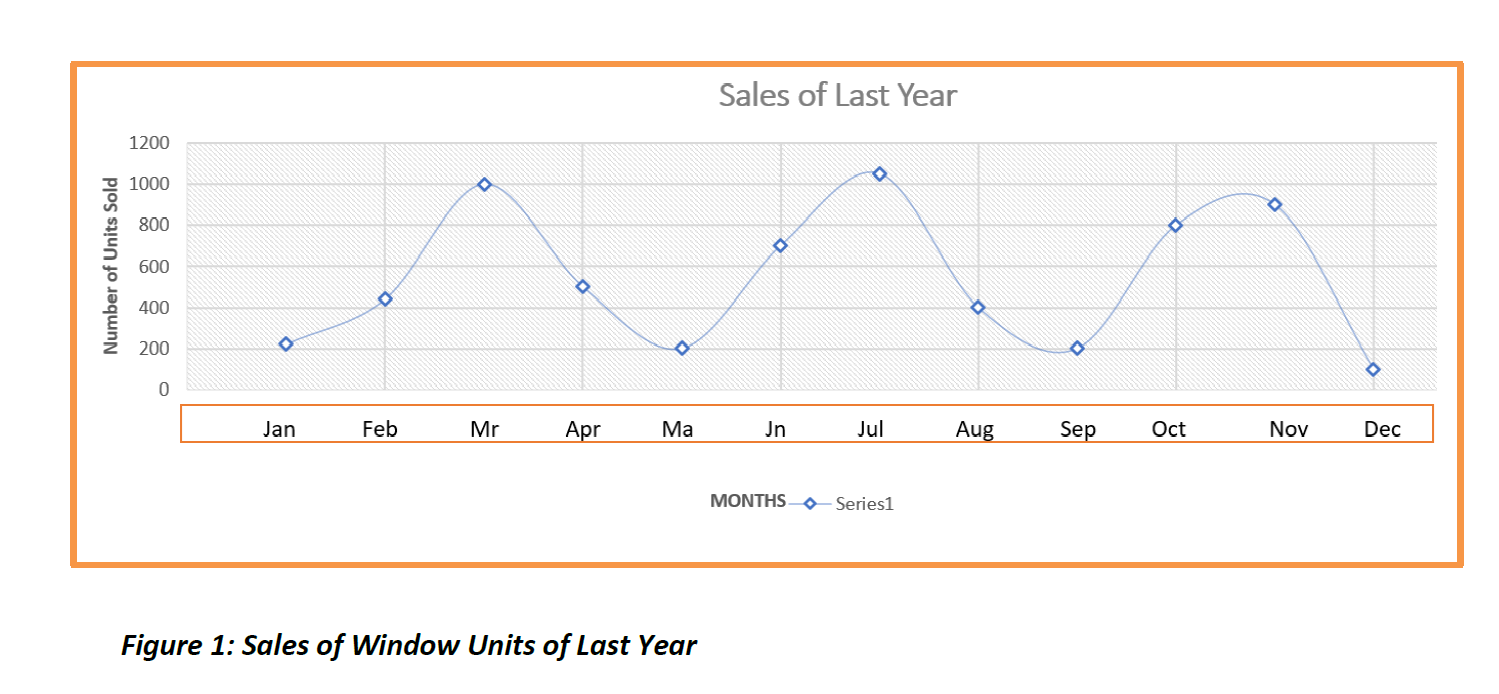

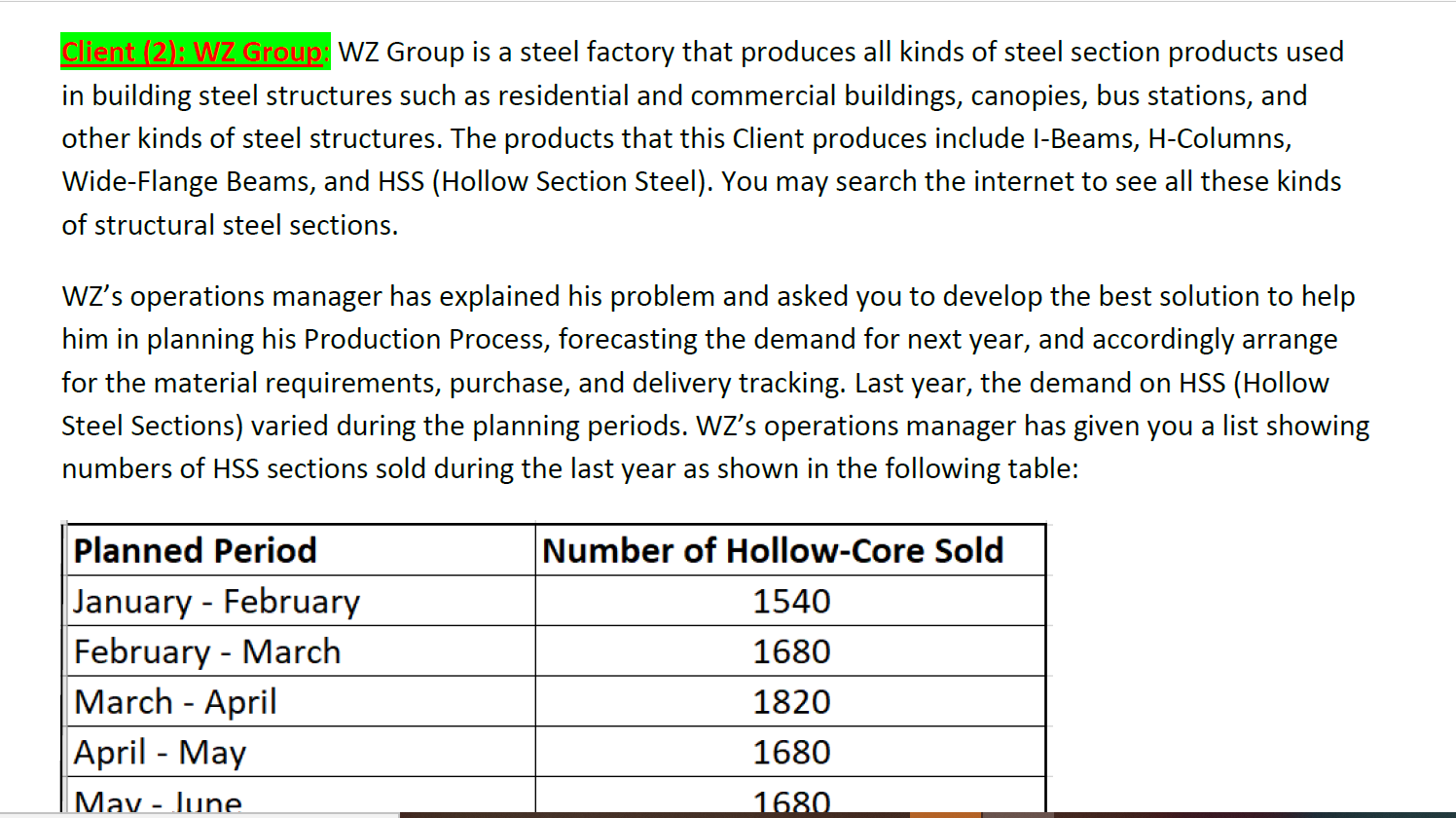

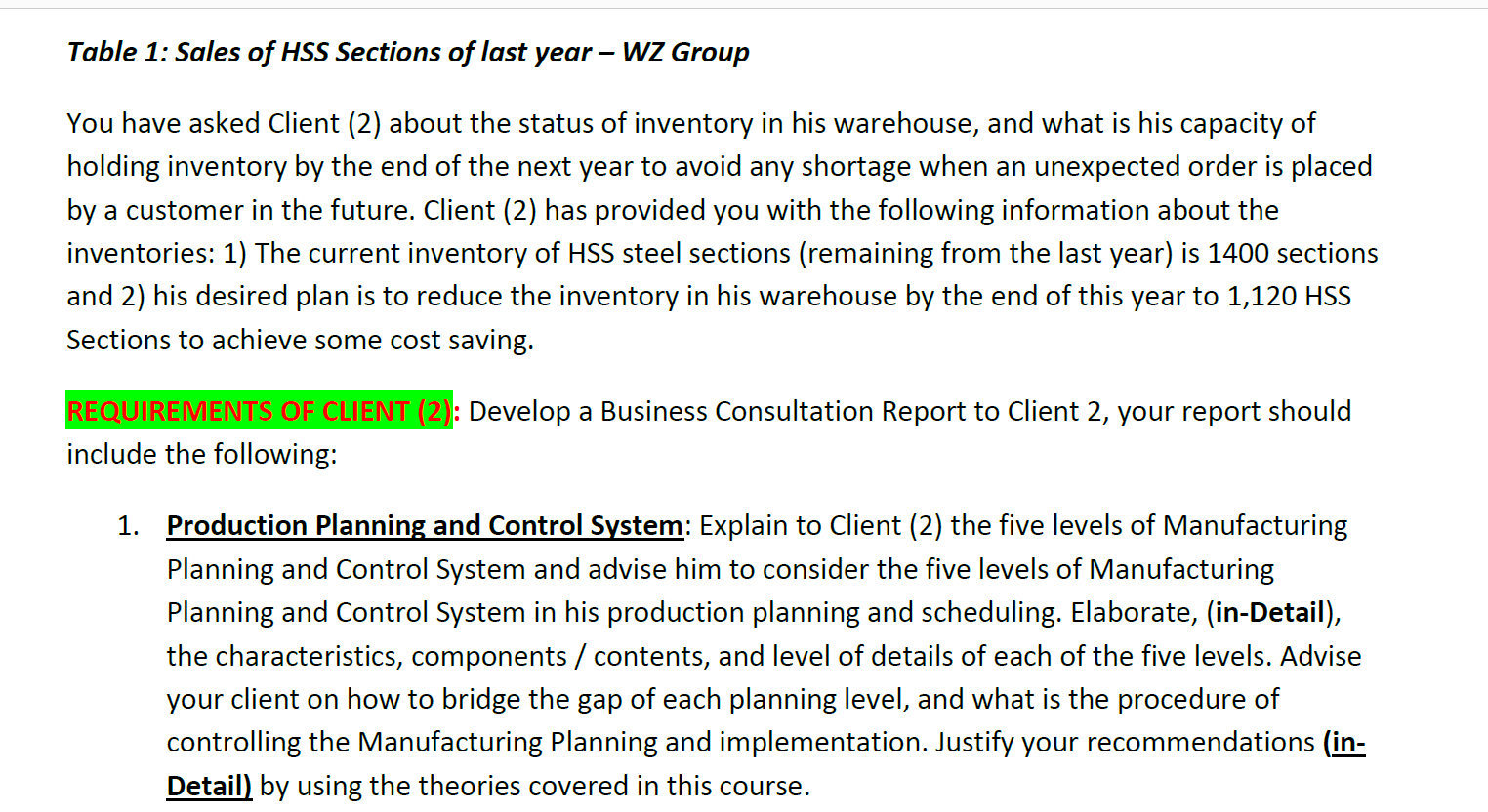

WZ's operations manager has explained his problem and asked you to develop the best solution to help him in planning his Production Process, forecasting the demand for next year, and accordingly arrange for the material requirements, purchase, and delivery tracking. Last year, the demand on HSS (Hollow Steel Sections) varied during the planning periods. WZ's operations manager has given you a list showing numbers of HSS sections sold during the last year as shown in the following table: Planned Period January - February February - March March - April April - May May - June Number of Hollow-Core Sold 1540 1680 1820 1680 1680 Table 1: Sales of HSS Sections of last year WZ Group You have asked Client (2) about the status of inventory in his warehouse, and what is his capacity of holding inventory by the end of the next year to avoid any shortage when an unexpected order is placed by a customer in the future. Client (2) has provided you with the following information about the Consider the following scenario: You are a group of business professionals recently hired by MC Business Consultants, a consulting firm specialized in providing consultation services to business organizations including producers of goods, material suppliers, distribution channels, service providers, and technology companies. Your scope of work includes meeting with clients, understanding their business problems and requirements, and developing business solutions to help clients solve their business issues, develop new competitive advantages, and expand their market shares. You have been approached by three potential Clients; each of them has a business problem and has asked you to solve the problem and present the solution in a Business Consultation Report, as detailed in the following descriptions: Sales of Last Year 1200 1000 o o 800 Number of Units Sold 600 400 200 O o 0 Jan Feb Mr Apr Ma Jn Jul Aug Sep Oct Nov Dec MONTHS Series1 Figure 1: Sales of Window Units of Last Year REQUIREMENTS OF CLIENT (1): Develop a complete Production Plan for Client (1). Your Production Plan should include the following: 1. Manufacturing Strategy: Analyze (in-Detail) the Product Characteristics and Client Requirements and recommend the best Manufacturing Strategy to GX Company. Do you recommend Engineer-to-Order? Or other manufacturing strategy? Why? Explain your recommended manufacturing strategy and justify your recommendations (in-Detail) by using the theories learned in this course and by giving practical examples from companies used or have been using the same manufacturing strategy that you recommend for your client. 2. Production Strategy: Analyze (in-Detail) the sales of last year given in Figure (1) and recommend the best Production Strategy to your client. Do you recommend the Demand Matching Strategy to your client? If your answer is YES, justify your answer (in-Detail). If your answer is NO, then what is the best Production Strategy for GX Company? Explain your recommended Production Strategy (in-Detail) and justify your recommendations by using the theories covered in this course and by giving practical examples from companies used or have been using the same production strategy that you recommend to your client. 3. Quantity of Product: Develop a detailed quantitative analysis showing how many windows should be produced for each period? 4. Ending Inventory: What is the Ending Inventory for Each Month? Can your Client achieve 50 windows ending inventory and reduce the cost of warehousing / storage? Justify your answer. 5. Cost of Carrying Inventory: If the cost of carrying inventory is $10 per window per month, what is the total cost of carrying inventory by the end of next year? 6. Demand Forecast Curve and Production Curve: Draw the Demand Forecast Curve and the Production Curve of next year and analyze the two curves. 7. Product Shortage / Surplus Strategy: Analyze your Demand Forecast and Production Curves: Do you expect shortage and surplus during next year? What is your strategy of handling the shortage to avoid Client dissatisfaction? What is your strategy of handling product surplus to minimize the cost of unsold windows? Explain your strategies (in-Detail) and justify your strategies. Client (2): WZ Group: WZ Group is a steel factory that produces all kinds of steel section products used in building steel structures such as residential and commercial buildings, canopies, bus stations, and other kinds of steel structures. The products that this Client produces include 1-Beams, H-Columns, Wide-Flange Beams, and HSS (Hollow Section Steel). You may search the internet to see all these kinds of structural steel sections. WZ's operations manager has explained his problem and asked you to develop the best solution to help him in planning his Production Process, forecasting the demand for next year, and accordingly arrange for the material requirements, purchase, and delivery tracking. Last year, the demand on HSS (Hollow Steel Sections) varied during the planning periods. WZ's operations manager has given you a list showing numbers of HSS sections sold during the last year as shown in the following table: Number of Hollow-Core Sold 1540 Planned Period January - February February - March March - April April - May May - June 1680 1820 1680 1680 Table 1: Sales of HSS Sections of last year WZ Group You have asked Client (2) about the status of inventory in his warehouse, and what is his capacity of holding inventory by the end of the next year to avoid any shortage when an unexpected order is placed by a customer in the future. Client (2) has provided you with the following information about the inventories: 1) The current inventory of HSS steel sections (remaining from the last year) is 1400 sections and 2) his desired plan is to reduce the inventory in his warehouse by the end of this year to 1,120 HSS Sections to achieve some cost saving. REQUIREMENTS OF CLIENT (2): Develop a Business Consultation Report to Client 2, your report should include the following: 1. Production Planning and Control System: Explain to Client (2) the five levels of Manufacturing Planning and Control System and advise him to consider the five levels of Manufacturing Planning and Control System in his production planning and scheduling. Elaborate, (in-Detail), the characteristics, components / contents, and level of details of each of the five levels. Advise your client on how to bridge the gap of each planning level, and what is the procedure of controlling the Manufacturing Planning and implementation. Justify your recommendations (in- Detail) by using the theories covered in this course. 2. Production Strategy: Analyze (in-Detail) the sales of last year given in Table (1) and the product characteristics and recommend the best Production Strategy to your client. Do you recommend the Demand Matching Strategy to your client? If your answer is YES, justify your answer (in- Detail). If your answer is NO, then what is the best Production Strategy for WZ Group? Explain your recommended Production Strategy (in-Detail) and justify your recommendations by using the theories covered in this course and by giving practical examples from companies used or have been using the same production strategy that you recommend to your client. 3. Quantity of Product: Develop a detailed quantitative analysis showing how many HSS steel sections should be produced each period next near. 4. Ending Inventory: Show the Ending Inventory of each planning period and how many steel sections (in TOTAL) are expected to remain in the warehouse by the end of next year. Hint: you need to achieve the 1,120 HSS Sections (ending inventory) as per the Client's requirements. 5. Cost Saving: If the cost of holding inventory in the warehouse is $ 4 per HSS Section per Period, what is the planned cost saving of the ending inventory of each planned period? What is the TOTAL nlanned cost saving of the ending inventory by the land of the Vear in November? 5. Cost Saving: If the cost of holding inventory in the warehouse is $ 4 per HSS Section per Period, what is the planned cost saving of the ending inventory of each planned period? What is the TOTAL planned cost saving of the ending inventory by the (end of the Year in November)? Client (3): GY Group: GY Group is a competitor of Client (2) in the market. The owner of GY Group has a steel factory that designs, produces, and sells various kinds of steel sections to construction companies. Client (3) has no problem in selling steel sections such as HSS Sections, but his problem is in forecasting the demand of unique, customer-designed steel sections that are to be used in specific areas such as roof structures of shopping malls and entrances of five-star hotels or luxury buildings. GY Group designs, manufactures, fabricates, and erects these types of steel structures based on customers' unique design requirements; therefore, the company charges clients differently. GY's sales manager splits the cost of design work from the cost of steel materials, manufacturing, fabrication, and erection works. Over the next five months of the forecast period, GY expects 2000 hours of design work per month. The existing backlog of design work is 2000 hours, and customers started complaining due to delay in the design process. Therefore, GY's owner told you that he wants to maximize client satisfaction by reducing the number of design backlog by the end of next five months (the planning period) to 1600 working hours instead of 2000 hours. REQUIREMENTS OF CLIENT (3): Develop a Business Consultation Report to Client 3, your report should include a solution to his demand forecast problem and a plan of reducing the backlog of design work as flows: 1. Production Strategy: Analyze Client's requirements and accordingly recommend to Client (3) the best Production Strategy that suits his design work. Do you recommend Demand-Matching Strategy? Production Leveling Strategy? Hybrid? Or other strategies? Justify your answer (in- Detail) by using the theories you have learned in this course and by giving practical examples. 2. Design Working Hours: Recommend to Client (3) how many design working hours will be required for each month during the coming five-month planning period to achieve the desired 1600 design hours backlog instead of the 2000 hours and improve client satisfaction. How many hours of design work blockage by the end each month of the planning period will be? 3. Draft the curve of the Demand Forecast (the forecasted design working hours based on last year), and the curve of Design Working Hours required Each Month (Production hours required per month to achieve the desired blockage). How do you see your recommended Production Plan for Client (3)? Explain the advantages of your plan to the client. Justify your answer. 1. Executive Summary: In the Executive Summary you may include a short INTODUCTION on the Case Study, the PURPOSE of analyzing the Case Study, the METHOD of ANALYSIS that you are going to use in solving the Case Study, RESULTS that you are going to present based on Case Study requirements, and the METHOD of Presenting the Results, such as by a Production Plan Report, Business Plan Report, Strategic Plan Report, etc. 2. Analysis: In the Analysis, you may explain the INPUTS given in the Case Study, such as Client Requirements, your Company Business Objectives, what your direct manager has asked you to do, and any other inputs you need to use in the analysis. Then, proceed with the ANALYSIS by exploring the Case Study Requirements given in the questions Q1, Q2, Q3, etc, and reply in-details with a precise, clear, thematically organized, and justified analysis 3. Results and Business Solution: Here you may present the results of your analysis. The Results may include your Recommendations, Business Decisions, and detailed Solutions All to be clearly justified with evidence. 3. Results and Business Solution: Here you may present the results of your analysis. The Results may include your Recommendations, Business Decisions, and detailed Solutions All to be clearly justified with evidence. Remember that in practical life as a Senior Manager, you will be responsible for your business decisions and recommendations to your company, because you are directing your employer to invest money, time, and other resources in what you recommend. You are putting your company reputation at the edge; therefore, your recommended solutions and business decisions must be well studied, justified, and convincing. 4. Conclusion: In the conclusion, you will summarize your work in a one short paragraph: Summarize the general guidelines and requirements of the Case Study, your analysis, results, recommendations, and business decisions. WZ's operations manager has explained his problem and asked you to develop the best solution to help him in planning his Production Process, forecasting the demand for next year, and accordingly arrange for the material requirements, purchase, and delivery tracking. Last year, the demand on HSS (Hollow Steel Sections) varied during the planning periods. WZ's operations manager has given you a list showing numbers of HSS sections sold during the last year as shown in the following table: Planned Period January - February February - March March - April April - May May - June Number of Hollow-Core Sold 1540 1680 1820 1680 1680 Table 1: Sales of HSS Sections of last year WZ Group You have asked Client (2) about the status of inventory in his warehouse, and what is his capacity of holding inventory by the end of the next year to avoid any shortage when an unexpected order is placed by a customer in the future. Client (2) has provided you with the following information about the Consider the following scenario: You are a group of business professionals recently hired by MC Business Consultants, a consulting firm specialized in providing consultation services to business organizations including producers of goods, material suppliers, distribution channels, service providers, and technology companies. Your scope of work includes meeting with clients, understanding their business problems and requirements, and developing business solutions to help clients solve their business issues, develop new competitive advantages, and expand their market shares. You have been approached by three potential Clients; each of them has a business problem and has asked you to solve the problem and present the solution in a Business Consultation Report, as detailed in the following descriptions: Sales of Last Year 1200 1000 o o 800 Number of Units Sold 600 400 200 O o 0 Jan Feb Mr Apr Ma Jn Jul Aug Sep Oct Nov Dec MONTHS Series1 Figure 1: Sales of Window Units of Last Year REQUIREMENTS OF CLIENT (1): Develop a complete Production Plan for Client (1). Your Production Plan should include the following: 1. Manufacturing Strategy: Analyze (in-Detail) the Product Characteristics and Client Requirements and recommend the best Manufacturing Strategy to GX Company. Do you recommend Engineer-to-Order? Or other manufacturing strategy? Why? Explain your recommended manufacturing strategy and justify your recommendations (in-Detail) by using the theories learned in this course and by giving practical examples from companies used or have been using the same manufacturing strategy that you recommend for your client. 2. Production Strategy: Analyze (in-Detail) the sales of last year given in Figure (1) and recommend the best Production Strategy to your client. Do you recommend the Demand Matching Strategy to your client? If your answer is YES, justify your answer (in-Detail). If your answer is NO, then what is the best Production Strategy for GX Company? Explain your recommended Production Strategy (in-Detail) and justify your recommendations by using the theories covered in this course and by giving practical examples from companies used or have been using the same production strategy that you recommend to your client. 3. Quantity of Product: Develop a detailed quantitative analysis showing how many windows should be produced for each period? 4. Ending Inventory: What is the Ending Inventory for Each Month? Can your Client achieve 50 windows ending inventory and reduce the cost of warehousing / storage? Justify your answer. 5. Cost of Carrying Inventory: If the cost of carrying inventory is $10 per window per month, what is the total cost of carrying inventory by the end of next year? 6. Demand Forecast Curve and Production Curve: Draw the Demand Forecast Curve and the Production Curve of next year and analyze the two curves. 7. Product Shortage / Surplus Strategy: Analyze your Demand Forecast and Production Curves: Do you expect shortage and surplus during next year? What is your strategy of handling the shortage to avoid Client dissatisfaction? What is your strategy of handling product surplus to minimize the cost of unsold windows? Explain your strategies (in-Detail) and justify your strategies. Client (2): WZ Group: WZ Group is a steel factory that produces all kinds of steel section products used in building steel structures such as residential and commercial buildings, canopies, bus stations, and other kinds of steel structures. The products that this Client produces include 1-Beams, H-Columns, Wide-Flange Beams, and HSS (Hollow Section Steel). You may search the internet to see all these kinds of structural steel sections. WZ's operations manager has explained his problem and asked you to develop the best solution to help him in planning his Production Process, forecasting the demand for next year, and accordingly arrange for the material requirements, purchase, and delivery tracking. Last year, the demand on HSS (Hollow Steel Sections) varied during the planning periods. WZ's operations manager has given you a list showing numbers of HSS sections sold during the last year as shown in the following table: Number of Hollow-Core Sold 1540 Planned Period January - February February - March March - April April - May May - June 1680 1820 1680 1680 Table 1: Sales of HSS Sections of last year WZ Group You have asked Client (2) about the status of inventory in his warehouse, and what is his capacity of holding inventory by the end of the next year to avoid any shortage when an unexpected order is placed by a customer in the future. Client (2) has provided you with the following information about the inventories: 1) The current inventory of HSS steel sections (remaining from the last year) is 1400 sections and 2) his desired plan is to reduce the inventory in his warehouse by the end of this year to 1,120 HSS Sections to achieve some cost saving. REQUIREMENTS OF CLIENT (2): Develop a Business Consultation Report to Client 2, your report should include the following: 1. Production Planning and Control System: Explain to Client (2) the five levels of Manufacturing Planning and Control System and advise him to consider the five levels of Manufacturing Planning and Control System in his production planning and scheduling. Elaborate, (in-Detail), the characteristics, components / contents, and level of details of each of the five levels. Advise your client on how to bridge the gap of each planning level, and what is the procedure of controlling the Manufacturing Planning and implementation. Justify your recommendations (in- Detail) by using the theories covered in this course. 2. Production Strategy: Analyze (in-Detail) the sales of last year given in Table (1) and the product characteristics and recommend the best Production Strategy to your client. Do you recommend the Demand Matching Strategy to your client? If your answer is YES, justify your answer (in- Detail). If your answer is NO, then what is the best Production Strategy for WZ Group? Explain your recommended Production Strategy (in-Detail) and justify your recommendations by using the theories covered in this course and by giving practical examples from companies used or have been using the same production strategy that you recommend to your client. 3. Quantity of Product: Develop a detailed quantitative analysis showing how many HSS steel sections should be produced each period next near. 4. Ending Inventory: Show the Ending Inventory of each planning period and how many steel sections (in TOTAL) are expected to remain in the warehouse by the end of next year. Hint: you need to achieve the 1,120 HSS Sections (ending inventory) as per the Client's requirements. 5. Cost Saving: If the cost of holding inventory in the warehouse is $ 4 per HSS Section per Period, what is the planned cost saving of the ending inventory of each planned period? What is the TOTAL nlanned cost saving of the ending inventory by the land of the Vear in November? 5. Cost Saving: If the cost of holding inventory in the warehouse is $ 4 per HSS Section per Period, what is the planned cost saving of the ending inventory of each planned period? What is the TOTAL planned cost saving of the ending inventory by the (end of the Year in November)? Client (3): GY Group: GY Group is a competitor of Client (2) in the market. The owner of GY Group has a steel factory that designs, produces, and sells various kinds of steel sections to construction companies. Client (3) has no problem in selling steel sections such as HSS Sections, but his problem is in forecasting the demand of unique, customer-designed steel sections that are to be used in specific areas such as roof structures of shopping malls and entrances of five-star hotels or luxury buildings. GY Group designs, manufactures, fabricates, and erects these types of steel structures based on customers' unique design requirements; therefore, the company charges clients differently. GY's sales manager splits the cost of design work from the cost of steel materials, manufacturing, fabrication, and erection works. Over the next five months of the forecast period, GY expects 2000 hours of design work per month. The existing backlog of design work is 2000 hours, and customers started complaining due to delay in the design process. Therefore, GY's owner told you that he wants to maximize client satisfaction by reducing the number of design backlog by the end of next five months (the planning period) to 1600 working hours instead of 2000 hours. REQUIREMENTS OF CLIENT (3): Develop a Business Consultation Report to Client 3, your report should include a solution to his demand forecast problem and a plan of reducing the backlog of design work as flows: 1. Production Strategy: Analyze Client's requirements and accordingly recommend to Client (3) the best Production Strategy that suits his design work. Do you recommend Demand-Matching Strategy? Production Leveling Strategy? Hybrid? Or other strategies? Justify your answer (in- Detail) by using the theories you have learned in this course and by giving practical examples. 2. Design Working Hours: Recommend to Client (3) how many design working hours will be required for each month during the coming five-month planning period to achieve the desired 1600 design hours backlog instead of the 2000 hours and improve client satisfaction. How many hours of design work blockage by the end each month of the planning period will be? 3. Draft the curve of the Demand Forecast (the forecasted design working hours based on last year), and the curve of Design Working Hours required Each Month (Production hours required per month to achieve the desired blockage). How do you see your recommended Production Plan for Client (3)? Explain the advantages of your plan to the client. Justify your answer. 1. Executive Summary: In the Executive Summary you may include a short INTODUCTION on the Case Study, the PURPOSE of analyzing the Case Study, the METHOD of ANALYSIS that you are going to use in solving the Case Study, RESULTS that you are going to present based on Case Study requirements, and the METHOD of Presenting the Results, such as by a Production Plan Report, Business Plan Report, Strategic Plan Report, etc. 2. Analysis: In the Analysis, you may explain the INPUTS given in the Case Study, such as Client Requirements, your Company Business Objectives, what your direct manager has asked you to do, and any other inputs you need to use in the analysis. Then, proceed with the ANALYSIS by exploring the Case Study Requirements given in the questions Q1, Q2, Q3, etc, and reply in-details with a precise, clear, thematically organized, and justified analysis 3. Results and Business Solution: Here you may present the results of your analysis. The Results may include your Recommendations, Business Decisions, and detailed Solutions All to be clearly justified with evidence. 3. Results and Business Solution: Here you may present the results of your analysis. The Results may include your Recommendations, Business Decisions, and detailed Solutions All to be clearly justified with evidence. Remember that in practical life as a Senior Manager, you will be responsible for your business decisions and recommendations to your company, because you are directing your employer to invest money, time, and other resources in what you recommend. You are putting your company reputation at the edge; therefore, your recommended solutions and business decisions must be well studied, justified, and convincing. 4. Conclusion: In the conclusion, you will summarize your work in a one short paragraph: Summarize the general guidelines and requirements of the Case Study, your analysis, results, recommendations, and business decisions