Question: You are attempting to develop a small scale reactor to carry out the reaction A + B C. Knowing that the reaction rate increases

![90 CAO To QH leeee VH 91 CA1 T VR qB TB 92 CA2 CB2 Cc2 T2 [26 Total Exam Points] [20 pts] Develop the](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2022/07/62c4157fe047d_Screenshot610.png)

![[6 pts] Given the information below about the system and the steady-state process inputs, calculate](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2022/07/62c4158b4ab34_Screenshot611.png)

![[END OF EXAM POINTS] [40 HW Points] Consider a scenario where process is running at steady-state and the](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2022/07/62c4159a7b22c_Screenshot612.png)

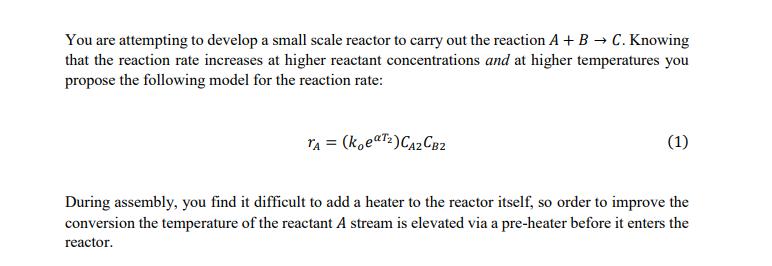

You are attempting to develop a small scale reactor to carry out the reaction A + B C. Knowing that the reaction rate increases at higher reactant concentrations and at higher temperatures you propose the following model for the reaction rate: T = (ke) CA2CB2 (1) During assembly, you find it difficult to add a heater to the reactor itself, so order to improve the conversion the temperature of the reactant A stream is elevated via a pre-heater before it enters the reactor. 90 CAO To QH leeee VH 91 CA1 T VR qB TB 92 CA2 CB2 Cc2 T2 [26 Total Exam Points] [20 pts] Develop the dynamic model for the entire system which would allow you to solve for the fractional conversion of species A, fa, as a function of the process inputs. Make the following assumptions to simplify the model: Consider all streams to have identical p and Cp Assume all fluid properties are constant (no temperature dependence) Assume the reactor to be insulated and that no heat is lost to the atmosphere Neglect any heat generated or consumed by the reaction [6 pts] Given the information below about the system and the steady-state process inputs, calculate steady-state values for T, T2, CAZ, CB2, CC2, and the fractional conversion of species A BE CAREFUL WITH UNITS Steady-State Process Inputs To = 5 L/min CAO = 1 mol/L To = 20C QH = 6 kW 9B = 8 L/min CBO=1 mol/L TB = 50C Process Parameters p = 1 kg/L Cp 4184J/kg. C = ko 0.1 L.mol-1 min-1 = = 0.15 C- VH = 2L VR = 10 L . [END OF EXAM POINTS] [40 HW Points] Consider a scenario where process is running at steady-state and the pre-heater suddenly shuts off (QH = 0) for ten minutes before turning back on (QH = 6 kW). Numerically model the effect of this change in input on the process outputs using finite differences. Note that all other inputs remain constant Directly use the model from the previous section... No need to linearize! This can be accomplished either by writing a short VBA code to loop through multiple time- steps or directly in Excel using each successive row as a new time-step. (a) Does the fractional conversion of species A deviate by more than 5 percent from its steady- state value? (b) Generate two plots. One displaying both T and T vs. time and another displaying the conversion of species A vs. time. Make sure that you cover enough time to observe the system reach its final steady-state behavior. [6 Bonus Exam Points] What is the value of the gain of the overall transfer function relating Q4 (s) to f(s)? Using this approach, how does the predicted change compare to that found using finite differences?

Step by Step Solution

3.48 Rating (155 Votes )

There are 3 Steps involved in it

Here is a graph showing the reaction rate as a functi... View full answer

Get step-by-step solutions from verified subject matter experts