Question: You are the lead engineer at a production facility, and you have been tasked with designing a machine consisting of two pulleys, two bearings, and

You are the lead engineer at a production facility, and you have been tasked with designing a machine

consisting of two pulleys, two bearings, and a shaft. The system will be designed to transmit torque from

Pulley A to Pulley C Pulley A must be located between the two bearings, while Pulley C must be

positioned at the free end of the shaft. Assume the bearings dont have any moment resistance ie

simplysupported beam

The total length of the shaft cannot exceed feet, but it should not be smaller than foot.

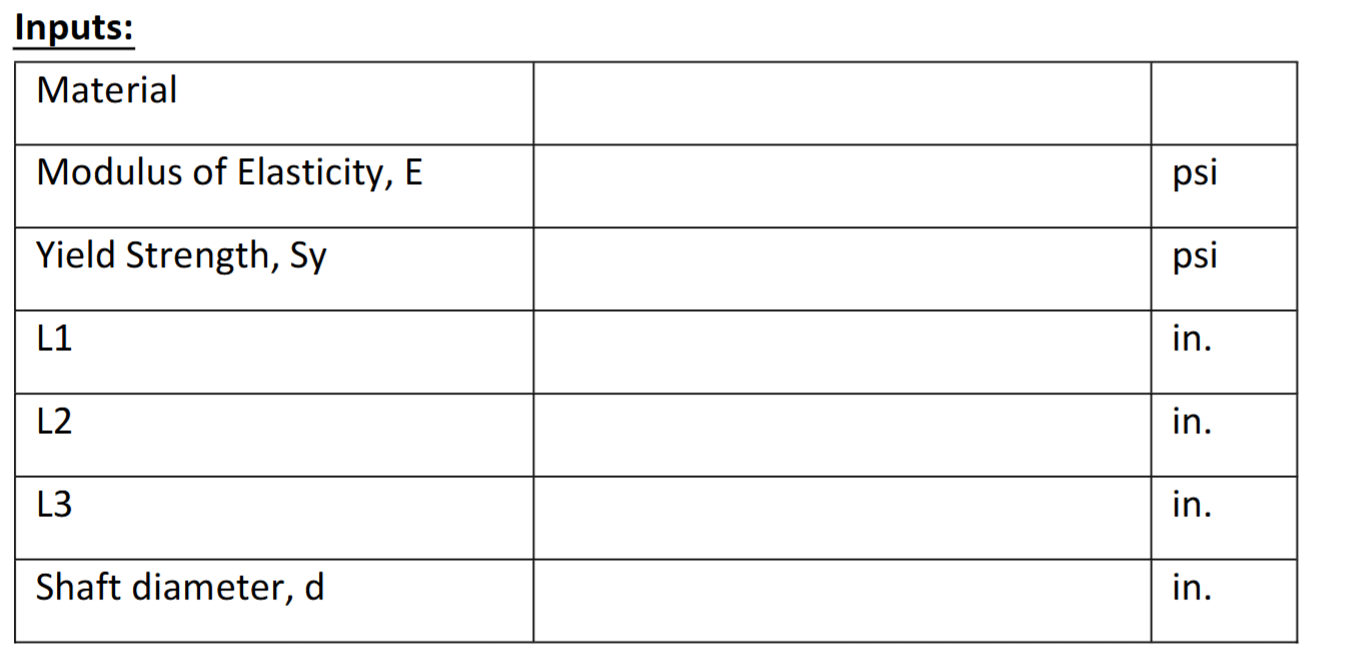

As the machine designer, specify a ductile material, and determine the lengths L L and L and

diameter d so that the material will not fail with a static factor of safety between and

With the dimensions that you have determined, find the deflection at point A at the location of the

pulley in between the two bearings

The device will operate at room temperature, and should have reliability. The shaft will be

machined. Using this information, find the shafts endurance strength and find the factor of safety for

infinite life. Note : The factor of safety for infinite life can be less than Note : You can neglect

stress concentrations

Fully document the calculations you used to arrive at these sizes L L and L including any

shearmoment diagrams you need and which failure theory you employed.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock