Question: you need to determine which variables on Table 5.2 you would keep in the model and why. In other words, what variables is the model

you need to determine which variables on Table 5.2 you would keep in the model and why. In other words, what variables is the model sensitive to? You dont need to do any calculations.

you need to determine which variables on Table 5.2 you would keep in the model and why. In other words, what variables is the model sensitive to? You dont need to do any calculations.

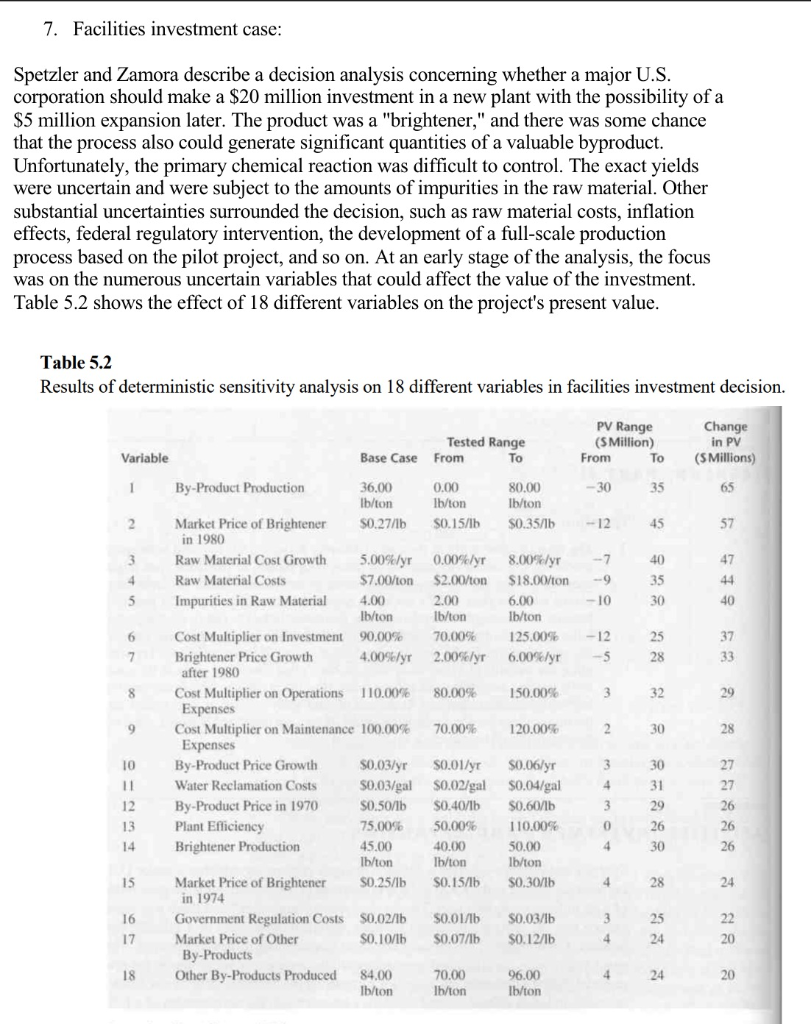

7. Facilities investment case: Spetzler and Zamora describe a decision analysis concerning whether a major U.S. corporation should make a $20 million investment in a new plant with the possibility of a $5 million expansion later. The product was a "brightener," and there was some chance that the process also could generate significant quantities of a valuable byproduct. Unfortunately, the primary chemical reaction was difficult to control. The exact yields were uncertain and were subject to the amounts of impurities in the raw material. Other substantial uncertainties surrounded the decision, such as raw material costs, inflation effects, federal regulatory intervention, the development of a full-scale production process based on the pilot project, and so on. At an early stage of the analysis, the focus was on the numerous uncertain variables that could affect the value of the investment. Table 5.2 shows the effect of 18 different variables on the project's present value. Table 5.2 Results of deterministic sensitivity analysis on 18 different variables in facilities investment decision. Tested Range Base Case From PV Range (5 Million) From Change in PV (5 Millions) Variable 1 By-Product Production -30 35 65 36.00 Ib/ton 0.00 Ib/ton S0.15/16 80.00 Ib/ton S0.35/16 2 Market Price of Brightener S0.27/16 - 12 45 57 in 1980 3 -7 40 47 4 44 35 30 5 10 40 8.00%/yr $18.00/ton 6.00 Ib/ton 125.00% 6.00%/yr 37 6 7 -12 5 25 28 33 8 150.00% 3 32 29 9 120.00% 2 30 28 Raw Material Cost Growth 5.00%/yr 0.00%/yr Raw Material Costs $7.00/ton $2.00/ton Impurities in Raw Material 4.00 2.00 Ib/ton Ib/ton Cost Multiplier on Investment 90,00% 70.00% Brightener Price Growth 4.00%/yr 2.00%/yr after 1980 Cost Multiplier on Operations 110.00% 80.00% Expenses Cost Multiplier on Maintenance 100.00% 70.00% Expenses By-Product Price Growth $0.03/yr S0.01/y Water Reclamation Costs $0.03/gal $0.02/gal By-Product Price in 1970 S0.50/1b $0.40/1b Plant Efficiency 75.005 50,00% Brightener Production 45.00 40.00 Ib/ton Ib/ton Market Price of Brightener S0.25/11 SO. 15/1b in 1974 Government Regulation Costs $0.02/1b S0.01/1b Market Price of Other S0.10/11 $0.07/1b By-Products Other By-Products Produced 84.00 70.00 Ib/ton Ib/ton 3 4 30 31 10 11 12 13 14 27 27 3 26 30.06/yr $0.04/gal $0.60/10 110.00% 50.00 1b/ton S0.30/1b 29 26 0 26 26 4 30 15 4 28 24 25 w 22 16 17 $0.03/1b $0.12/1b 4 24 20 18 4 24 20 96.00 Ib/ton 7. Facilities investment case: Spetzler and Zamora describe a decision analysis concerning whether a major U.S. corporation should make a $20 million investment in a new plant with the possibility of a $5 million expansion later. The product was a "brightener," and there was some chance that the process also could generate significant quantities of a valuable byproduct. Unfortunately, the primary chemical reaction was difficult to control. The exact yields were uncertain and were subject to the amounts of impurities in the raw material. Other substantial uncertainties surrounded the decision, such as raw material costs, inflation effects, federal regulatory intervention, the development of a full-scale production process based on the pilot project, and so on. At an early stage of the analysis, the focus was on the numerous uncertain variables that could affect the value of the investment. Table 5.2 shows the effect of 18 different variables on the project's present value. Table 5.2 Results of deterministic sensitivity analysis on 18 different variables in facilities investment decision. Tested Range Base Case From PV Range (5 Million) From Change in PV (5 Millions) Variable 1 By-Product Production -30 35 65 36.00 Ib/ton 0.00 Ib/ton S0.15/16 80.00 Ib/ton S0.35/16 2 Market Price of Brightener S0.27/16 - 12 45 57 in 1980 3 -7 40 47 4 44 35 30 5 10 40 8.00%/yr $18.00/ton 6.00 Ib/ton 125.00% 6.00%/yr 37 6 7 -12 5 25 28 33 8 150.00% 3 32 29 9 120.00% 2 30 28 Raw Material Cost Growth 5.00%/yr 0.00%/yr Raw Material Costs $7.00/ton $2.00/ton Impurities in Raw Material 4.00 2.00 Ib/ton Ib/ton Cost Multiplier on Investment 90,00% 70.00% Brightener Price Growth 4.00%/yr 2.00%/yr after 1980 Cost Multiplier on Operations 110.00% 80.00% Expenses Cost Multiplier on Maintenance 100.00% 70.00% Expenses By-Product Price Growth $0.03/yr S0.01/y Water Reclamation Costs $0.03/gal $0.02/gal By-Product Price in 1970 S0.50/1b $0.40/1b Plant Efficiency 75.005 50,00% Brightener Production 45.00 40.00 Ib/ton Ib/ton Market Price of Brightener S0.25/11 SO. 15/1b in 1974 Government Regulation Costs $0.02/1b S0.01/1b Market Price of Other S0.10/11 $0.07/1b By-Products Other By-Products Produced 84.00 70.00 Ib/ton Ib/ton 3 4 30 31 10 11 12 13 14 27 27 3 26 30.06/yr $0.04/gal $0.60/10 110.00% 50.00 1b/ton S0.30/1b 29 26 0 26 26 4 30 15 4 28 24 25 w 22 16 17 $0.03/1b $0.12/1b 4 24 20 18 4 24 20 96.00 Ib/ton

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts