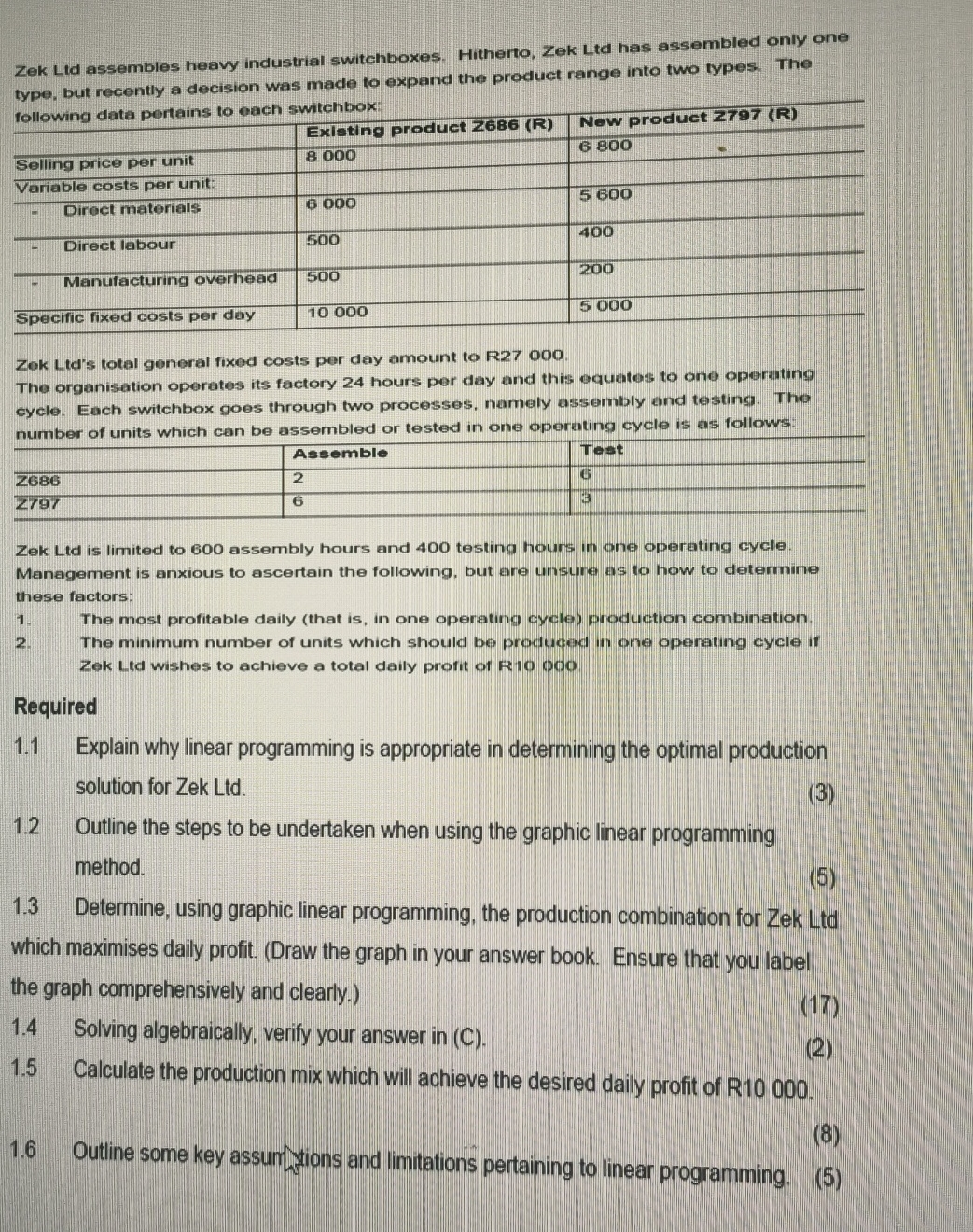

Zek Ltd assembles heavy industrial switchboxes. Hitherto, Zek Ltd has assembled only one type, but recently a decision was made to expand the product range into two types. The following data pertains to each switchbox:

tablefollowing data pertains to each switchbox:,,Existing product ZRNew product ZRSelling price per unit,Variable costs per unit:,, Direct materials,Direct labour, Manufacturing overhead,Specific fixed costs per day,

Zek Ltds total general fixed costs per dey amount to R

The organisation operates its factory hours per day and this equates to one operating cycle. Each switchbox goes through two processes, namely assembly and testing. The number of units which can be assembled or tested in one operating cycle is as follows:

tableAssemble,Test

Zek Ltd is limited to assembly hours and testing hours in one operating cycle. Management is anxious to ascertain the following, but are unsure as to how to determine these factors:

The most profitable daily that is in one operating cycle production combination.

The minimum number of units which should be produced in one operating cycle if Zek Ltd wishes to achieve a total daily profit of R

Required

Explain why linear programming is appropriate in determining the optimal production solution for Zek Ltd

Outline the steps to be undertaken when using the graphic linear programming method.

Determine, using graphic linear programming, the production combination for Zek Ltd which maximises daily profit. Draw the graph in your answer book. Ensure that you label the graph comprehensively and clearly.

Solving algebraically, verify your answer in C

Calculate the production mix which will achieve the desired daily profit of R

Outline some key assumitions and limitations pertaining to linear programming.