Plant capacity for the methanolwater distillation of Exercise 7.41 is to be doubled. Rather than installing a

Question:

Plant capacity for the methanol–water distillation of Exercise 7.41 is to be doubled. Rather than installing a second, identical rayed tower, a packed column is being considered. This would have a feed location, product purities, reflux ratio, operating pressure, and capacity identical to the present trayed tower. Two packings are being considered:

(1) 50-mm plastic Nor-Pac rings (a random packing), and (2) Montz metal B1-300 (a structured packing).

For each of these packings, design a column to operate at 70% of flooding by calculating for each section:

(a) Liquid holdup,

(b) Column diameter,

(c) HOG,

(d) Packed height, and

(e) Pressure drop. What are the advantages, if any, of each of the packed-column designs over a second trayed tower? Which packing, if either, is preferable?

Data From Exercise 7.41

Performance data for a distillation tower separating a 50/50 by weight percent mixture of methanol and water are as follows:

Feed rate = 45,438 lb/h; feed condition = bubble-point liquid at feed-tray pressure;

Wt% methanol in distillate = 95.04; Wt% methanol in bottoms = 1.00;

Reflux ratio = 0.947; reflux condition = saturated liquid;

Boilup ratio = 1.138; pressure in reflux drum = 14.7 psia;

Type condenser = total; type reboiler = partial;

Condenser pressure drop = 0.0 psi; tower pressure drop = 0.8 psi;

Trays above feed tray = 5; trays below feed tray = 6;

Total trays = 12; tray diameter = 6 ft; type tray = single-pass

sieve tray; flow path length = 50.5 inches;

Weir length = 42.5 inches; hole area = 10%; hole size = 3/16 inch;

Weir height = 2 inches; tray spacing = 24 inches;

Viscosity of feed = 0.34 cP; Surface tension of distillate = 20 dyne/cm;

Surface tension of bottoms = 58 dyne/cm;

Temperature of top tray = 154°F; temperature of bottom tray = 207°F

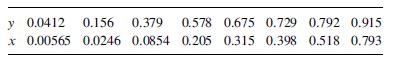

Vapor–liquid equilibrium data at column pressure in mole fraction of methanol are

Based on the above data:

(a) Determine the overall tray efficiency assuming the reboiler is equivalent to a theoretical stage.

(b) Estimate the overall tray efficiency from the Drickamer–Bradford correlation.

(c) Estimate the overall tray efficiency from the O’Connell correlation, accounting for length of flow path.

(d) Estimate the Murphree vapor-tray efficiency by the method of Chan and Fair.

Step by Step Answer:

Separation Process Principles Chemical And Biochemical Principles

ISBN: 9780470481837

3rd Edition

Authors: By J. D. Seader, Ernest J. Henley, D. Keith Roper