In high-volume machining centers, cutting tools are replaced at regular, heuristically chosen intervals. These intervals are generally

Question:

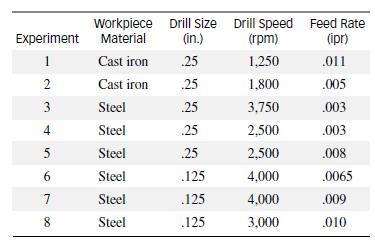

In high-volume machining centers, cutting tools are replaced at regular, heuristically chosen intervals. These intervals are generally untimely, i.e., either the tool is replaced too early or too late. The Journal of Engineering for Industry (Aug. 1993) reported on an automated real-time diagnostic system designed to replace the cutting tool of a drilling machine at optimum times. To test the system, data were collected over a broad range of machining conditions. The experimental variables were as follows:1. Two workpiece materials (steel an d cast iron) 2. Two drill sizes (.125 and .25 inch) 3. Six drill speeds (1,250, 1,800, 2,500, 3,000, 3,750, and 4,000 revolutions per minute) 4. Seven feed rates (.003, .005, .0065, .008, .009, .010, .011 inches per revolution)

a. How many different machining conditions are possible?

b. The eight machining conditions actually employed in the study are described in the table on pg. 123. Suppose one (and only one) of the machining combinations in part a will detect a flaw in the system. What is the probability that the experiment conducted in the study will detect the system flaw?

c. Refer to part b. Suppose the system flaw occurs when drilling steel material with a .25-inch drill size at a speed of 2,500 rpm. Find the probability that the experiment conducted in the actual study will detect the system flaw.

Step by Step Answer:

Statistics For Engineering And The Sciences

ISBN: 9781498728850

6th Edition

Authors: William M. Mendenhall, Terry L. Sincich