Question: The controller for Tulsa Photographic Supply Company has established the following activity cost pools and cost drivers. An order for 1,000 boxes of film development

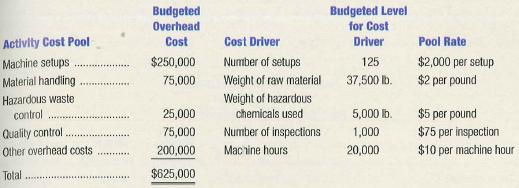

The controller for Tulsa Photographic Supply Company has established the following activity cost pools and cost drivers.

An order for 1,000 boxes of film development chemicals has the following production requirements.

Machine setups ……………………… 5 Setups

Raw material ………………………… 10,000 pounds

Hazardous materials ……………….... 2,000 pounds

Inspections ………………………… 10 inspections

Machine hours ……………………… 500 machine hours

Required:

1. Compute the total overhead that should be assigned to the development-chemical order.

2. What is the overhead cost per box of chemicals?

3. Suppose Tulsa Photographic Supply Company was to use a single predetermined overhead rate based on machine hours, Compute the rate per hour.

4. Under the approach in requirement (3), how much overhead would be assigned to the development chemical order?

a. In total,

b. Per box of chemicals.

5. Explain why these two product-costing systems result in such widely differing costs. Which system do you recommend? Why?

Budgeted Overhead Cost Budgeted Level for Cost Activity Cost Pool Machine selupS Material handing Hazardous waste Driver 125 75,000 Weight of raw material 37,500 Pool Rate $2,000 per setup Cost Driver $250,000 Number of setups $2 per pound Weight of hazardous chemicals used 25,000 5,000b. $5per pound control Quality contreol Other overhead costs Total 75,000 Number of inspections 1,000 20,000 $75 per inspection $10 per machine hour $625,000

Step by Step Solution

3.19 Rating (160 Votes )

There are 3 Steps involved in it

1 Overhead to be assigned to film development chemical order Activity Cost Pool Pool Rate Level of C... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

238-B-M-A-A-B-C (807).docx

120 KBs Word File