Question: A process for the separation of a propylene-propane mixture to produce 99 mol% propylene and 95 mol% propane is shown in figure. Because of the

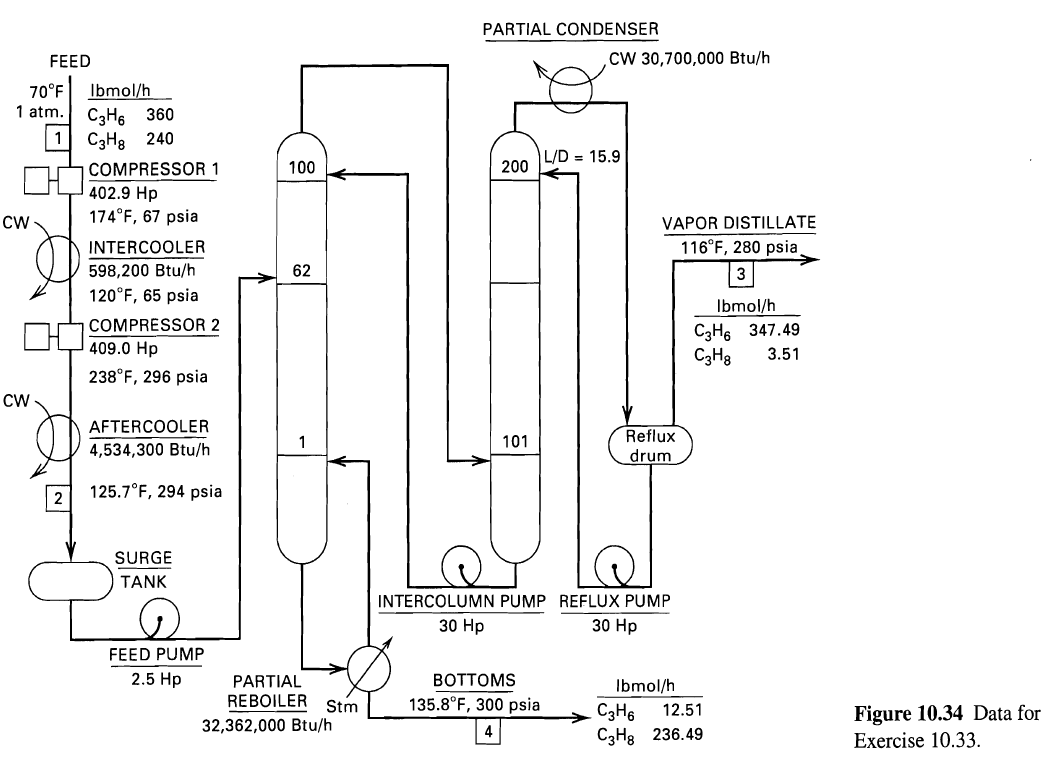

A process for the separation of a propylene-propane mixture to produce 99 mol% propylene and 95 mol% propane is shown in figure. Because of the high product purities and the low relative volatility, 200 stages may be required. Assuming a tray efficiency of 100% and tray spacing of 24 inches, this will necessitate the two columns shown in series, because a single tower would be too tall. Assume a vapor distillate pressure of 280 psia, a pressure drop of 0.1 psi per tray, and a 2-psi drop through the condenser. The stage numbers and reflux ratio shown are only approximate. Determine the necessary reflux ratio for the stage numbers shown. Pay close attention to the determination of the proper feedstage location so as to avoid pinch or near-pinch conditions wherein several adjacent trays may not be accomplishinganything.

PARTIAL CONDENSER CW 30,700,000 Btu/h FEED 70F 1 atm. Ibmol/h 360 240 L/D = 15.9 200 100 COMPRESSOR 1 402.9 Hp 174F, 67 psia CW VAPOR DISTILLATE 116F, 280 psia INTERCOOLER 598,200 Btu/h 62 120F, 65 psia Ibmol/h COMPRESSOR 2 347.49 C 409.0 Hp 3.51 238F, 296 psia CW- AFTERCOOLER Reflux 101 4,534,300 Btu/h drum 125.7F, 294 psia SURGE TANK INTERCOLUMN PUMP REFLUX PUMP 30 30 Hp FEED PUMP 2.5 Hp BOTTOMS PARTIAL REBOILER Stm Ibmol/h 135.8F, 300 psia C3H3 236.49 12.51 Figure 10.34 Data for 32,362,000 Btu/h 4 Exercise 10.33.

Step by Step Solution

3.35 Rating (158 Votes )

There are 3 Steps involved in it

The calculations were made with the SCDS Column model Simultaneouscorrection method because of the s... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

37-E-C-E-S-P (396).docx

120 KBs Word File