Consider the following hypothetical situation in the computer industry. HP had been outsourcing production to Acer and

Question:

Consider the following hypothetical situation in the computer industry. HP had been outsourcing production to Acer and using overtime for as much as 20% of production—HP’s plants and assembly lines were running at 100% of capacity and demand was sufficient for an additional 20%. HP had considered increasing its capacity by building new, highly automated assembly lines and plants. However, the investment in high technology and capacity expansion was rejected.

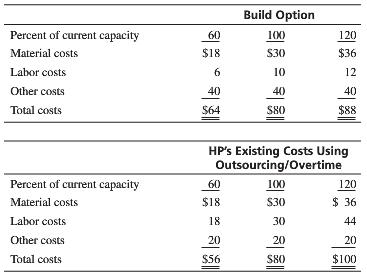

Assume that all material and labor costs are variable with respect to the level of production and that all other costs are fixed. Consider one of HP’s plants that makes the Pavillion model. The increase in annual fixed costs to convert the plant to use fully automated assembly lines is $20 million. The resulting labor costs would be significantly reduced and there would be no need for overtime or out-sourced production. The annual costs, in millions of dollars, of the build option and the existing costs that include outsourcing and overtime are given in the following tables:

1. Prepare a line graph showing total costs for the two options:

(a) Build new assembly lines, and

(b) Continue to use overtime and outsource production of Pavillions. Give an explanation of the cost behavior of the two options.

2. Which option enables HP’s management to control risk better? Explain. Assess the cost-benefit trade-offs associated with each option.

3. A solid understanding of cost behavior is an important prerequisite to effective managerial control of costs. Suppose you are an executive at HP. Currently the production (and sales) level is approaching the 100% level of capacity, and the economy is expected to remain strong for at least 1 year. While sales and profits are good now, you are aware of the variability inherent in the computer business. Would you recommend committing HP to building automated assembly lines in order to service potential near-term increases in demand? Or would you recommend against building, looking to the possible future downturn in business? Discuss your reasoning.

Step by Step Answer:

Introduction to Management Accounting

ISBN: 978-0133058789

16th edition

Authors: Charles Horngren, Gary Sundem, Jeff Schatzberg, Dave Burgsta