Question: Deciding where to produce (CMA, adapted) The Domestic Engines Co. produces the same power generators in two Illinois plants, a new plant in Peoria and

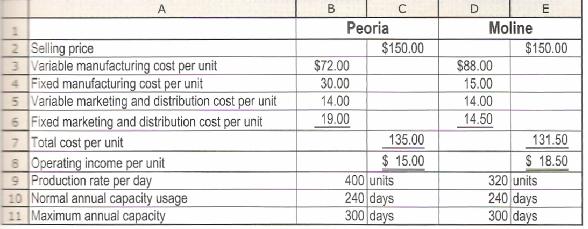

Deciding where to produce (CMA, adapted) The Domestic Engines Co. produces the same power generators in two Illinois plants, a new plant in Peoria and an older plant in Moline. The following data are available for the two plants:

All fixed costs per unit are calculated based on a normal capacity usage consisting of 240 working days. When the number of working days exceeds 240, overtime charges raise the variable manufacturing costs of addition units by $3.00 per unit in Peoria and $8.00 per unit in Moline. Domestic Engines Cc. is expected to produce and sell 192,000 power generators during the coming wanting to take advantage of the higher operating income per unit at Moline, the company’s product manager has decided to manufacture 96,000 units at each plant, resulting in a plan in which Moline operates at capacity (320 units per day X 300 days) and Peoria operates at its normal volume (400 units per X 240 days). If you want to use Excel to solve this problem, go to the Excel Lab at www.prenhall.com/horngren/costl3e and download the template for Problem 3-49.

1. Calculate the breakeven point in units for the Peoria plant and for the Moline plant

2. Calculate the operating income that would result from the production manager’s plan to produce 96,000 units at each plant.

3. Determine how the production of 192,000 units should be allocated between the Peoria and Moline plants to maximize operating income for Domestic Engines. Show your calculations.

Peoria Moline $150.00 2 Selling price 3 Variable manufacturing cost per unit 4 Fixed manufacturing cost per unit 5 Variable marketing and distribution cost per unit 6 Fixed marketing and distribution cost per unit $150.00 $72.00 $88.00 15.00 14.00 14.50 14.00 19.00 135.00 $ 15.00 400 units 240 days 300 days 131.50 7 Total cost per unit 8 Operating income per unit 9 Production rate per day 10 Normal annual capacity usage 11 Maximum annual capacity $ 18.50 320 units 240 days 300 days

Step by Step Solution

3.53 Rating (184 Votes )

There are 3 Steps involved in it

Deciding where to produce 1 2 3 The optimal production plan is to produce 120000 units at the Peoria ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

24-B-C-A-C-P-A (139).docx

120 KBs Word File