Question: For the phenol-formaldehyde (Bakelite) polymer, whose stress strain behavior may be observed in the Tensile Tests module of Virtual Materials Science and Engineering (VMSE), determine

For the phenol-formaldehyde (Bakelite) polymer, whose stress strain behavior may be observed in the "Tensile Tests" module of Virtual Materials Science and Engineering (VMSE), determine the following:

(a) The tensile strength, and

(b) The approximate ductility, in percent elongation.

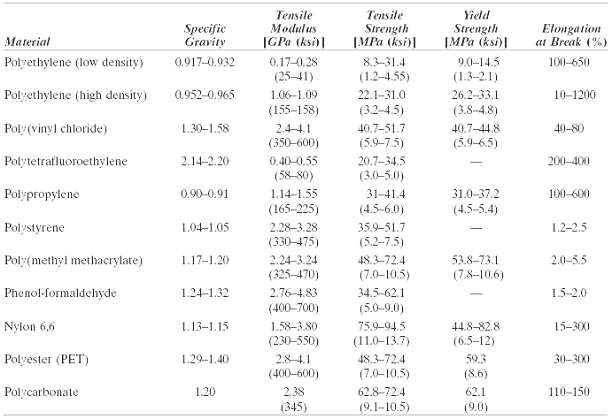

How do these values compare with those for the phenol-formaldehyde material presented in Table15.1?

Tensile Modulus |GPa (ksi)| Tensile Yield Specific Gravity Strength |MPa (ksi) Strength [MPa (ksi)| Elongation at Break (%) Material Polyethylene (low density) 0.917-0,032 0.17-0.28 (25-41) 8.3-31.4 (1.2-4.55) 0.0-14.5 (1.3-2.1) 100-650 1.06-1.09 (155-158) 0.952-0,965 26.2-33.1 10-1200 Polyethylene (high density) 22.1-31.0 (3.2-4.5) (3.8-4.8) Poly (vinyl chloride) 40-80 1.30-1.58 2.4-4.1 40.7-51.7 40.7-44.8 (350-600) (5.9-7.5) (5.9-6.5) Polytetrafluoroethylene 2.14-2.20 0.40-0.55 20.7-34.5 200-400 (58-80) (3.0-5.0) Polypropylene 0.90-0.91 1.14-1.55 31-41.4 31.0-37.2 100-600 (165-225) (4.5-6.0) (4.5-5.4) Polystyrene 1.2-2.5 1.04-1.05 2.28-3.28 35.9-51.7 (330-475) (5.2-7.5) Poly(methyl methacrylate) 1.17-1.20 2.24-3.24 (325-470) 48.3-72.4 (7.0-10.5) 53.8-73.1 2.0-5.5 (7.8-10.6) Phenol-formaldehyde 1.24-1.32 2.76-4.83 34.5-62.1 1.5-2.0 (400-700) (5.0-9.0) 1.58-3.80 Nylon 6,6 L.13-1.15 75.9-94.5 44.8-82.8 15-300 (230-550) (11.0-13.7) (6.5-12) Polyester (PET) 1.29-1.40 30-300 2.8-4.1 (400-600) 48.3-72.4 (7.0-10.5) 59.3 (8.6) Polcarbonate 1.20 2.38 62.8-72.4 62.1 110-150 (345) (9.1-10.5) (9.0)

Step by Step Solution

3.36 Rating (162 Votes )

There are 3 Steps involved in it

a The tensile strength corresponds to the stress ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

33-E-M-S-E-M-S (564).docx

120 KBs Word File