Question: In a manufacturing process, a fluid is transported through a cellar maintained at a temperature of 300 K. The fluid is contained in a pipe

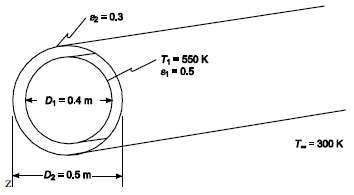

In a manufacturing process, a fluid is transported through a cellar maintained at a temperature of 300 K. The fluid is contained in a pipe having an external diameter of 0.4 m and whose surface has an emissivity of 0.5. To reduce heat losses, the pipe is surrounded by a thin shielding pipe having an ID of 0.5 m and an emissivity of 0.3. The space between the two pipes is effectively evacuated to minimize heat losses and the inside pipe is at a temperature of 550 K.(a) Estimate the heat loss from the liquid per meter length,(b) If the fluid inside the pipe is an oil flowing at a velocity of 1 m/s, calculate the length of pipe for a temperature drop of 1 K.GIVENFluid in concentric pipes, with the space between the pipes evacuated, running through a cellar spaceCellar temperature (T??) = 300 KExternal diameter of inner pipe (D1) = 0.4 mEmissivity of outer pipe surface (ε1) = 0.5Inside diameter of outer pipe (D2) = 0.5 mEmissivity of inner pipe (ε 2) = 0.3Inside pipe temperature (T1) = 550 KASSUMPTIONSSteady stateConvection between the pipes is negligibleThe thermal resistance of the pipe walls is negligibleThe thickness of the outer pipe wall is negligible (Inside surface area ?? Outside surface area)Area of the cellar is large compared to the pipe so that cellar behaves as a blackbody enclosure at T??Oil has the thermal properties of unused engine oilThe temperature of the inner pipe isconstant

=0.3 T- 550 K &- 0.5 D; =04 m T= 300 K -D2=0,5 m-

Step by Step Solution

3.42 Rating (171 Votes )

There are 3 Steps involved in it

The rate of heat transfer between the pipes is given by Equation 975 where F 12 is give... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

66-E-M-E-H-M-T (1929).docx

120 KBs Word File