Question: Schultz Electronics manufactures two large-screen television models: the Royale which sells for 1,600, and a new model, the Majestic, which sells for 1,300. The production

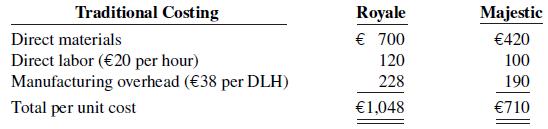

Schultz Electronics manufactures two large-screen television models: the Royale which sells for €1,600, and a new model, the Majestic, which sells for €1,300. The production cost computed per unit under traditional costing for each model in 2020 was as follows.

In 2020, Schultz manufactured 25,000 units of the Royale and 10,000 units of the Majestic. The overhead rate of €38 per direct labor hour was determined by dividing total expected manufacturing overhead of €7,600,000 by the total direct labor hours (200,000) for the two models.

Under traditional costing, the gross profi t on the models was Royale €552 or (€1,600 − €1,048), and Majestic €590 or (€1,300 − €710). Because of this diff erence, management is considering phasing out the Royale model and increasing the production of the Majestic model.

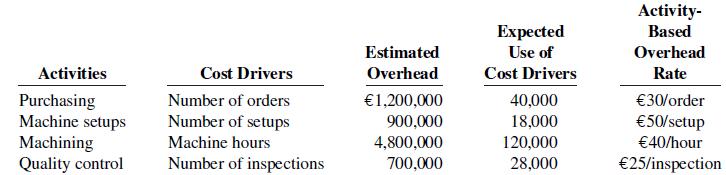

Before finalizing its decision, management asks Schultz’s controller to prepare an analysis using activity-based costing (ABC). The controller accumulates the following information about overhead for the year ended December 31, 2020.

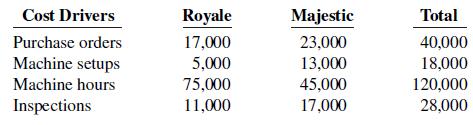

The cost drivers used for each product were:

Instructions

a. Assign the total 2020 manufacturing overhead costs to the two products using activity-based costing (ABC) and determine the overhead cost per unit.

b. What was the cost per unit and gross profi t of each model using ABC?

c. Are management’s future plans for the two models sound? Explain.

Traditional Costing Royale Majestic Direct materials 700 420 Direct labor (20 per hour) Manufacturing overhead (38 per DLH) 120 100 228 190 Total per unit cost 1,048 710

Step by Step Solution

3.58 Rating (169 Votes )

There are 3 Steps involved in it

Solution Given that Activity Overhead Cost Purchasing 1200000 Machine setups 900000 Machining 480000... View full answer

Get step-by-step solutions from verified subject matter experts