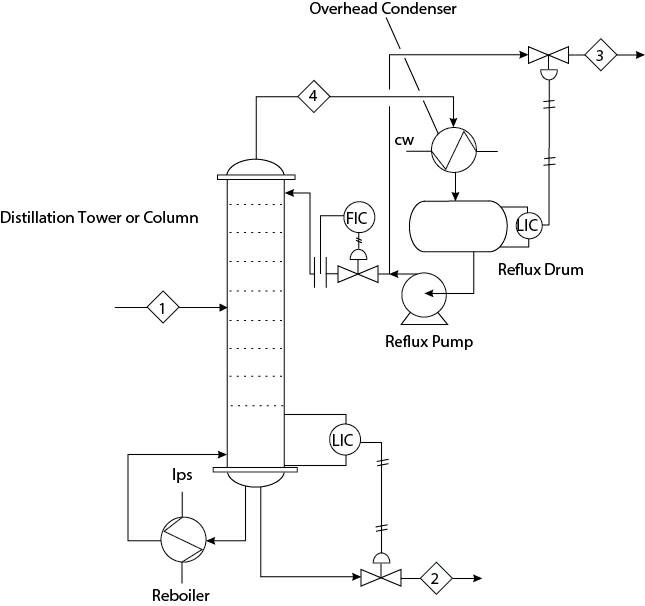

A typical binary distillation column and related equipment are shown in Figure P14.9. When designing distillation columns,

Question:

A typical binary distillation column and related equipment are shown in Figure P14.9.

When designing distillation columns, it is common to optimize the column using the reflux ratio, R, as the decision variable. The overall cost of building the column and running it must be considered when optimizing the design. The capital investment (cost) for the equipment includes the cost of the column plus the costs of the reboiler, condenser, reflux drum, and reflux pump. For this project consider only the costs of the column and the two heat exchangers (reboiler and condenser). The operating costs include the cost of the cooling medium (water) for the condenser and the heating medium (steam) for the reboiler. Because the equipment costs are one-time purchase costs and the operating costs (steam and water) occur all the time, the time value of money must be taken into consideration when defining an objective function. For this project it is desired to minimize the equivalent annual operating cost (EAOC) of the column that is defined in Equation (P14.9.1):![EAOC[$/y] = PC;[8] (A/P,i,n) [1/3] + Quc; [8/3] i=1 i=1 (P14.9.1)](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/3/5/0/114654a06620dd721699350111290.jpg)

where PCi is the purchase cost of the column and heat exchangers, and UCi is the operating (utility) cost (cooling water and steam). Assume that the effective interest rate, i, is 8% p.a. and that the length of the project, n, is 10 years.

It is desired to optimize a distillation column (calculate the value of R that minimizes the EAOC) to separate 1000 kmol/h of an equal molar feed of benzene and toluene into a top product containing 99.5 mol% benzene with a recovery of benzene of 98%. The recovery of benzene refers to the ratio of total amount (kmol) of benzene in the top product to that entering in the feed. The column is to operate at a pressure of 1 atm. yi is defined as the mole fraction of benzene in the top stream, and xi as the mole fraction of benzene in the bottom stream.

The relationship between the reflux ratio, R, and the number of stages or trays in the column, N, is given by the following relationships:

![Rmin X - = Y = 1- exp 2 a-1 R-Rmin R+1 { [ 11 []} 1+54.4X 11+117.2X (P14.9.4) (P14.9.5) (P14.9.6)](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/3/5/0/216654a06c8a27d61699350214702.jpg)

where α is the relative volatility of the benzene with respect to the toluene, which is equal to 2.3 for this system. The costs of utilities for the overhead condenser (cooling water = cw) and reboiler (steam) are given by![UCew [$/h] = $3.54 x 10-7VXv UC steam [$/h] =20UCew [$/h] (P14.9.7) (P14.9.8)](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/3/5/0/233654a06d921dde1699350229652.jpg)

where lV is the latent heat of vaporization (kJ/kmol) of benzene at its normal boiling point, and V (kmol/h) is the total vapor flow from the top of the column. The purchase cost of the column is given by![]()

where VCOl = pD2L/4 is the volume of the column in m3 and D[m] and L[m] are the diameter and height of the column, respectively. The diameter and height of the column are given by![D[m] = 0.15(V[kmol/h])0.5 L[m] = N (P14.9.11) (P14.9.10)](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/3/5/0/297654a07195fab01699350294508.jpg)

The purchase costs of the condenser and reboiler may be taken as 10% and 20% of the cost of the column, respectively.

Present your final results as two plots. The first should show how each term in Equation (P14.9.1) changes with R/Rmin, and the second plot should show the EAOC (y-axis) as a function of R/Rmin (x-axis). Explain the reason for the trends seen in each of these plots.

Step by Step Answer:

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780134177403

5th Edition

Authors: Richard Turton, Joseph Shaeiwitz, Debangsu Bhattacharyya, Wallace Whiting