Determine the bare module, total module, and grassroots cost of the following: Ethylbenzene plant described in Appendix

Question:

Determine the bare module, total module, and grassroots cost of the following:

Ethylbenzene plant described in Appendix B, Project B.2

![B.2.1 Process Description [1, 2] The PFD for the EB process is shown in Figure B.2.1. A refinery cut of](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/2/6/9/7476548cc73220d51699269745005.jpg)

![[DEB]) is taken as the top product and is sent directly to the styrene unit. The bottoms product from T-302](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/2/6/9/7666548cc8620f241699269764077.jpg)

Transcribed Image Text:

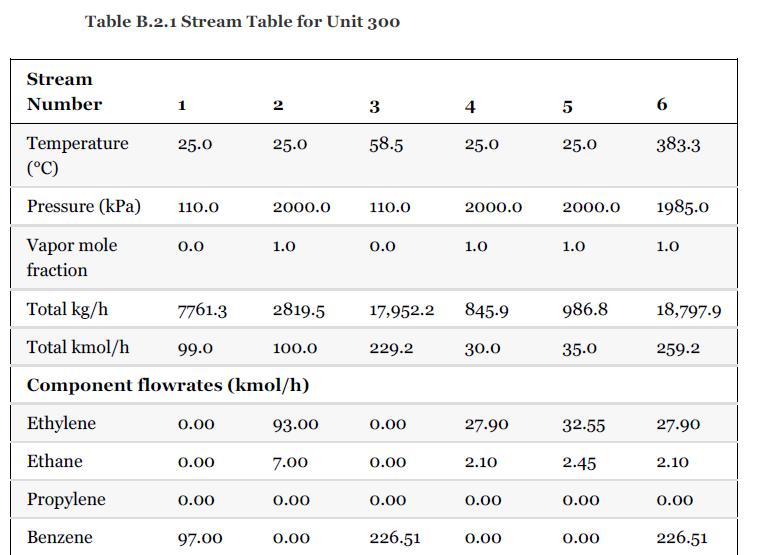

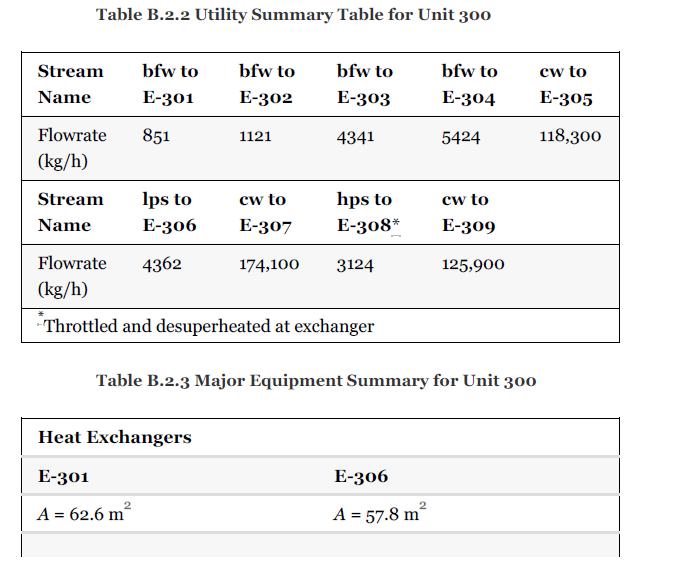

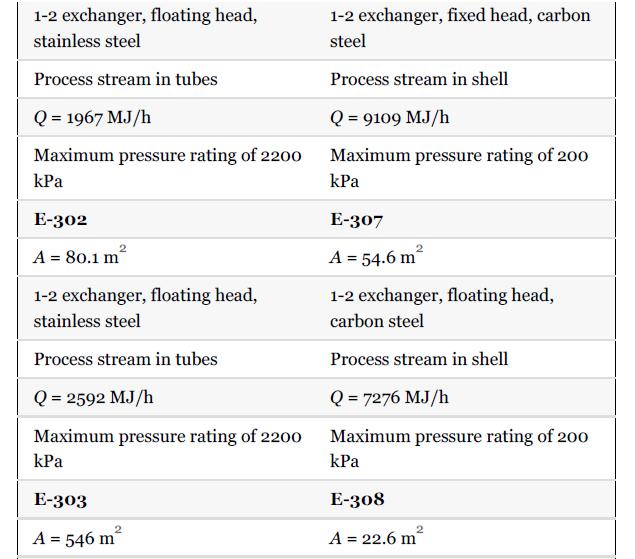

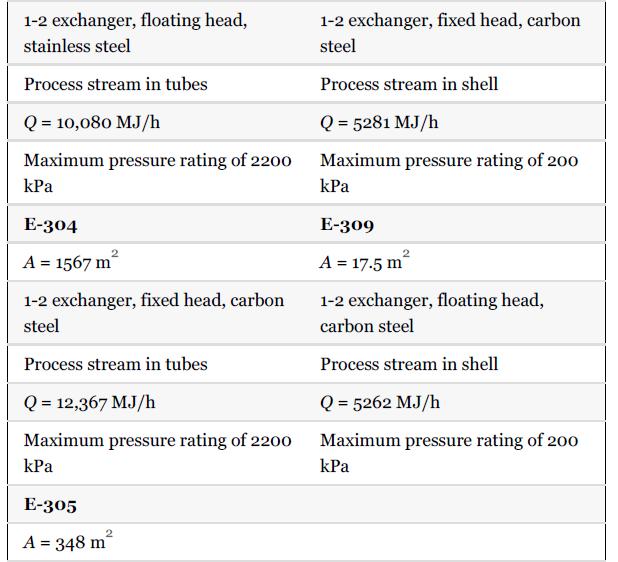

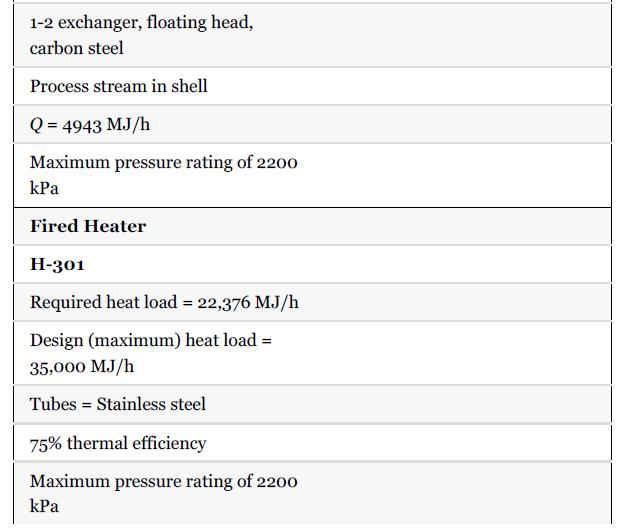

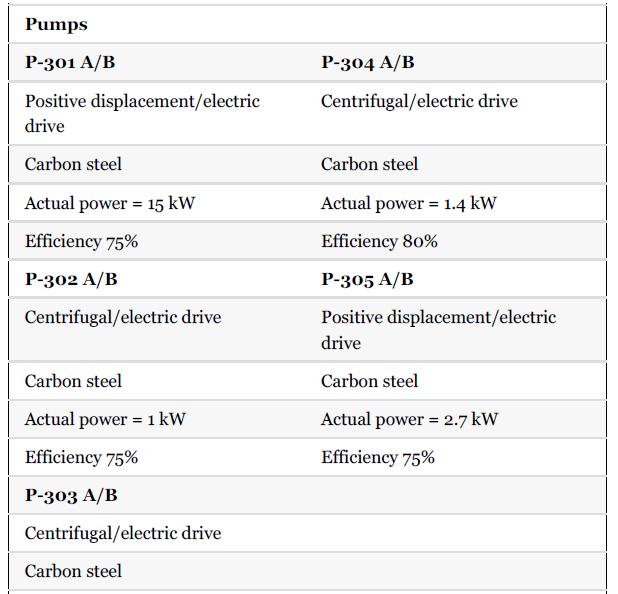

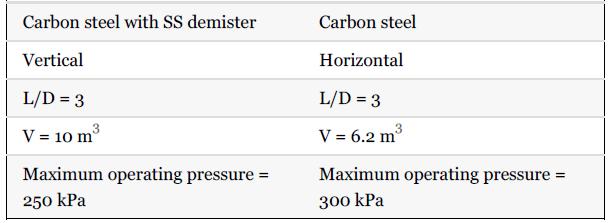

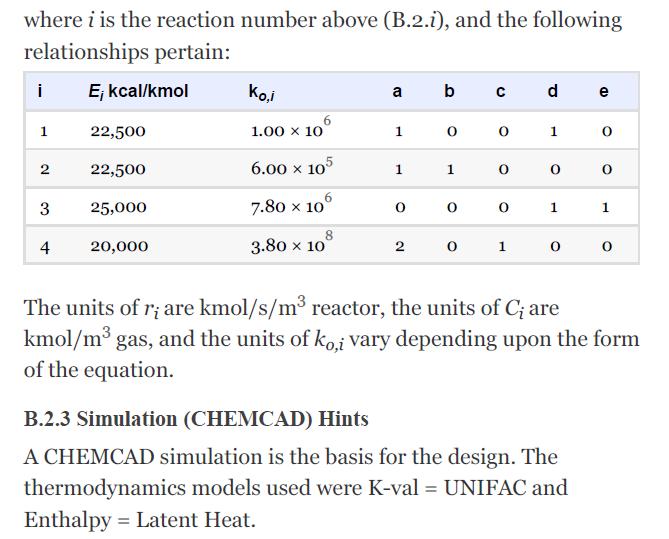

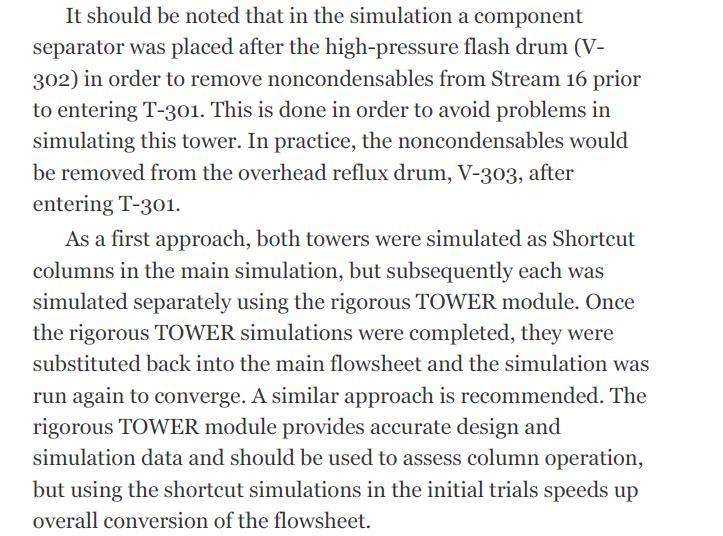

B.2 ETHYLBENZENE PRODUCTION, UNIT 300 The majority of ethylbenzene (EB) processes produce EB for internal consumption within a coupled process that produces styrene monomer. The facility described here produces 80,000 tonne/y of 99.8 mol % ethylbenzene that is totally consumed by an on-site styrene facility. As with most EB/styrene facilities, there is significant heat integration between the two plants. In order to decouple the operation of the two plants, the energy integration is achieved by the generation and consumption of steam within the two processes. The EB reaction is exothermic, so steam is produced, and the styrene reaction is endothermic, so energy is transferred in the form of steam.

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Answer rating: 100% (1 review)

Answered By

David Ngaruiya

i am a smart worker who concentrates on the content according to my clients' specifications and requirements.

4.50+

7+ Reviews

19+ Question Solved

Related Book For

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780134177403

5th Edition

Authors: Richard Turton, Joseph Shaeiwitz, Debangsu Bhattacharyya, Wallace Whiting

Question Posted:

Students also viewed these Engineering questions

-

Determine the bare module, total module, and grassroots cost of the following: Styrene plant described in Appendix B, Project B.3 Figure B.3.1 B.3 STYRENE PRODUCTION, UNIT 400 Styrene is the monomer...

-

Estimate the cost of operating labor (C OL ), the cost of utilities (C UT ), and the cost of manufacturing (COM d ) for the ethylbenzene process given in Project B.2 of Appendix B. You must do...

-

Estimate the cost of operating labor (C OL ), the cost of utilities (C UT ), and the cost of manufacturing (COM d ) for the styrene process given in Project B.3 of Appendix B. You must do Problem...

-

Consider the plane stress inhomogeneous case with only variation in elastic modulus given by E = E(y) = 1/ (Ay + B). Further assume that the Airy function depends only on y, = (y). Show that...

-

The cash account for Alpine Sports Co. on April 1, 2006, indicated a balance of $16,911.95. During April, the total cash deposited was $65,500.40, and checks written totaled $68,127.47. The bank...

-

High ethical standards are distinguishing features of which of the following bodies? A. Craft guilds B. Trade bodies C. Professional bodies

-

In a 1975 contract, Eureka was given the exclusive right to sell spring water and other products under the Ozarka trade name in 60 Oklahoma counties in exchange for \($9,000\) paid to Arrowhead,...

-

Mutual Insurance Company of Iowa (MICI) has a major insurance office facility located in Des Moines, Iowa. The Des Moines office is responsible for processing all of MICIs insurance claims for the...

-

Design Deterministic Finite Automata with for each of the following independent specifications. Design a DFA that accepts the words that have odd number of's. Design a DFA where the members of has at...

-

Determine the bare module, total module, and grassroots cost of the following: Drying oil plant described in Appendix B, Project B.4 Figure B.4.1 B.4 DRYING OIL PRODUCTION, UNIT 500 Drying oils are...

-

Using the results of Problem 7.13, determine the relative costs of the vessel using the two materials of construction (CS and 316 SS) over the temperature range. You may assume that the cost of the...

-

Identify the variances from standard cost that are generally computed for direct materials, direct labor, and manufacturing overhead.

-

Dozer, Inc. is a closely-held corporation incorporated in a state that has adopted the Model Business Corporation Act. Prior to 2012, Dozers business was organized into two divisions; neither was...

-

3 The label on a company's energy drinks claims that they contain an average caffeine concentration of 250 mg/oz. The mean caf- feine concentration of 15 randomly sampled drinks was 267, with a...

-

You must use the Law of Sines and the Law of Cosines. The air velocity of a jet is 400 km/h [S 30 W]. A 70 km/h wind is blowing from [N20W]. Determine the ground velocity of the jet. Include a proper...

-

My office has two chairs and I like students to be able to sit down when they come to office hours. I don't mind standing. Suppose that 1% of students in the class I teach attends my office hours....

-

A justly-intonated "perfect fifth" in musical harmony is described by a frequency ratio of 3:2. A perfect fifth is a very pleasant pair of notes to hear. An "octave" is a culturally universal musical...

-

Selected information taken from the financial statements of Maxum Company for two successive years follows. You are to compute the percentage change from 2010 to 2011 whenever possible. Round all...

-

Consider the reaction of acetic acid in water CH 3 CO 2 H(aq) + H 2 O(l) CH3CO 22 (aq) + H 3 O + (aq) where Ka 5 1.8 3 1025. a. Which two bases are competing for the proton? b. Which is the stronger...

-

In a process that produces a temperature-sensitive product, the final step is to cool the product from \(70^{\circ} \mathrm{C}\) to \(35^{\circ} \mathrm{C}\) prior to sending it to storage. This...

-

A heat exchanger was put into service approximately one year ago. The design conditions are that process gas is cooled from \(100^{\circ} \mathrm{C}\) to \(50^{\circ} \mathrm{C}\), with cooling water...

-

Assume that the distillation column in Figure 21. 16 is to be operated at the same value of \(L_{0}, D\), and \(B\) and the same feed as the base case. Figure 21.16 a. Calculate \(x_{D}, x_{B}\), and...

-

Daniela works as an architect. She has a disability insurance policy that specifies a monthly benefit for total disability of $8000. Last year she suffered an illness that caused a total disability....

-

Jim used an automobile 75% for business and 25% for personal in 20X1. He incurred $5,000 in total expenses for the automobile. What is the largest amount of vehicle expenses that Jim can claim as a...

-

You are thinking about opening a food truck focused on Poke Bowls outside of Haas. There is some existing competition, but it serves "Poke Bowls" in which the fish is cooked, so no one will go there...

Study smarter with the SolutionInn App