For the styrene production process given in Project B.3 in Appendix B, do the following: 1. Construct

Question:

For the styrene production process given in Project B.3 in Appendix B, do the following:

1. Construct a process conditions matrix (PCM) for the process, and determine all conditions of special concern.

2. Explain the reasons for using the conditions of special concern in the reactor.

3. Suggest any process alternatives for Part (b).

Transcribed Image Text:

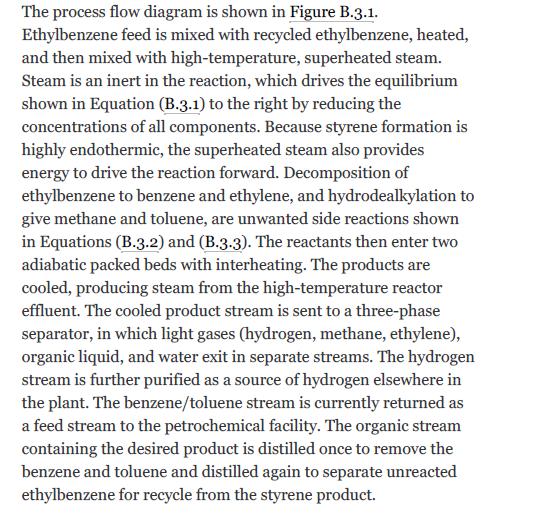

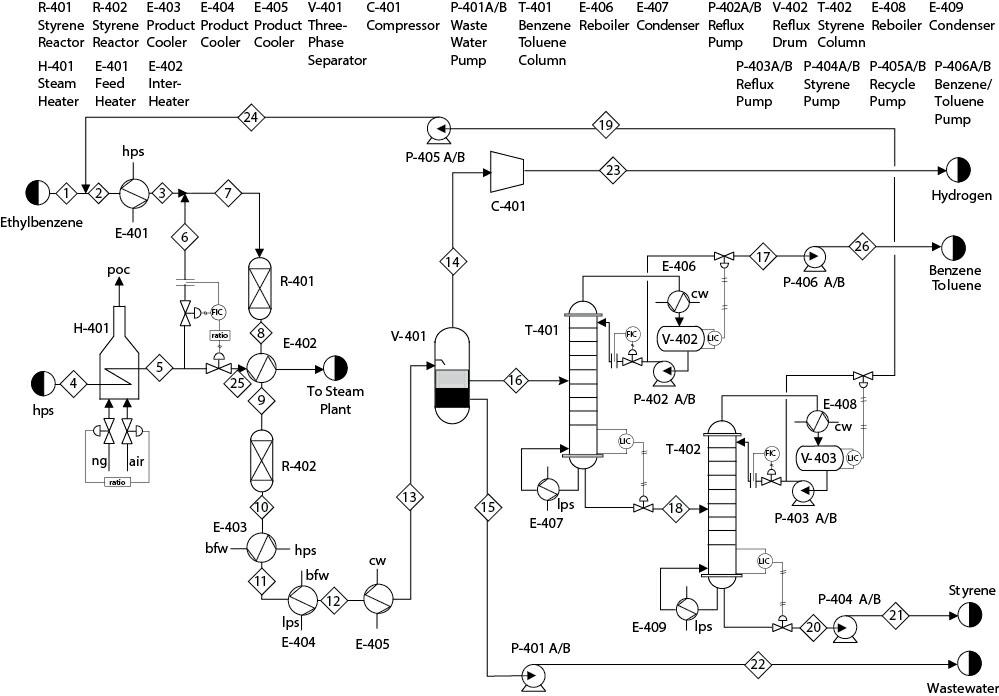

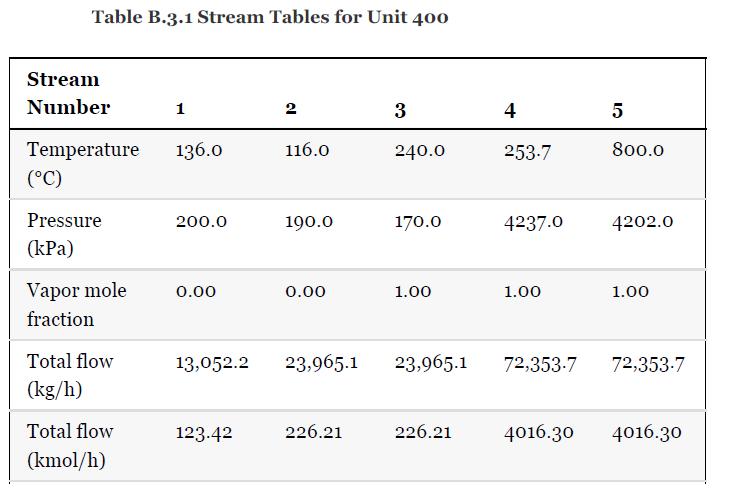

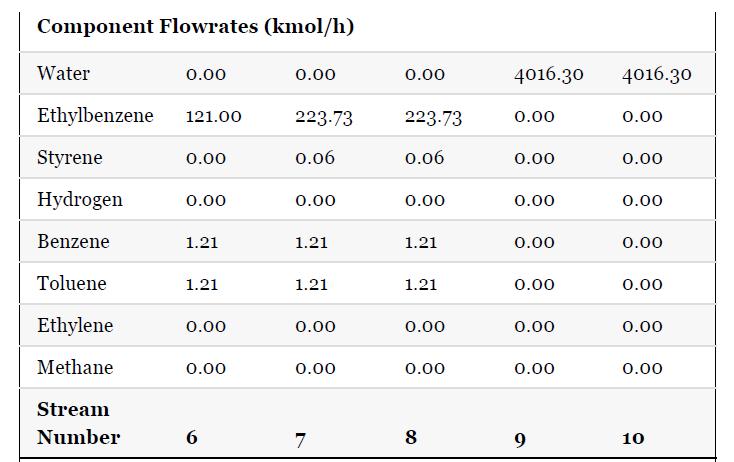

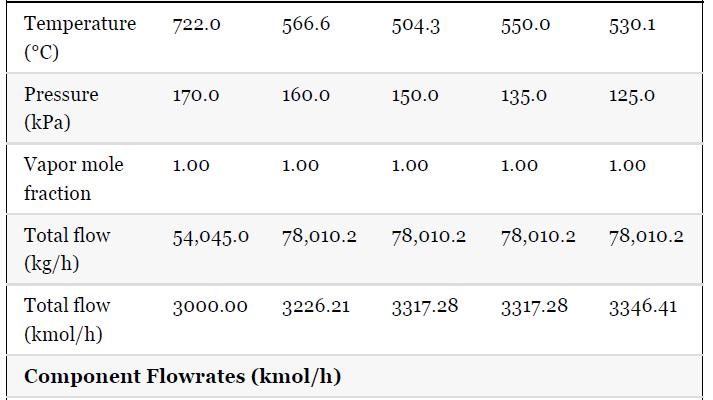

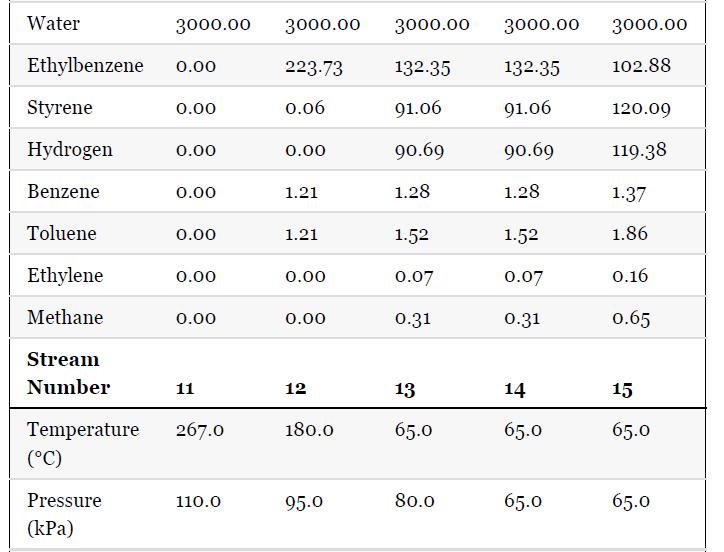

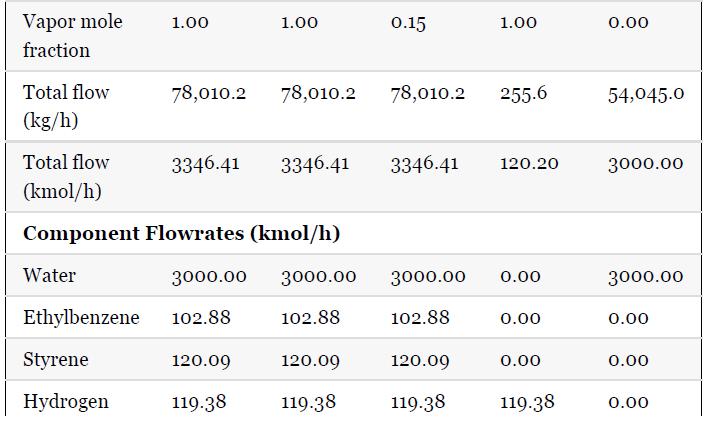

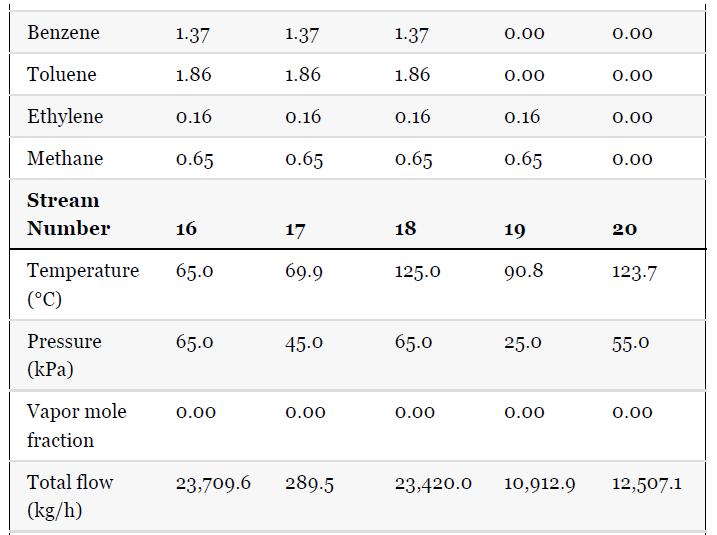

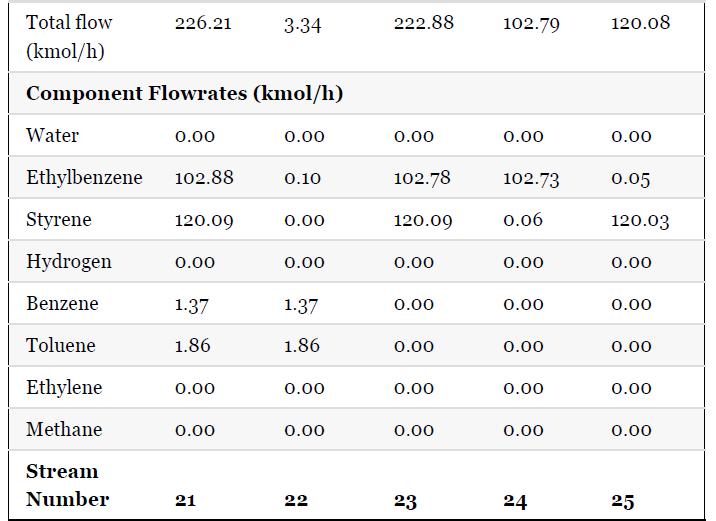

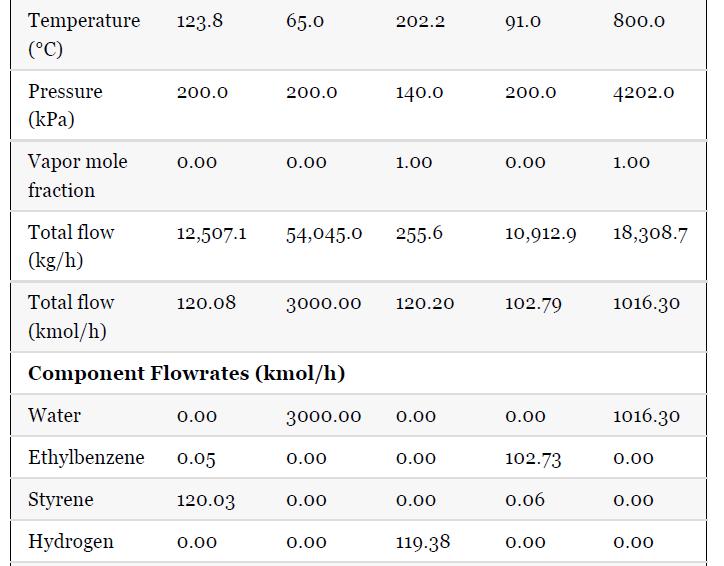

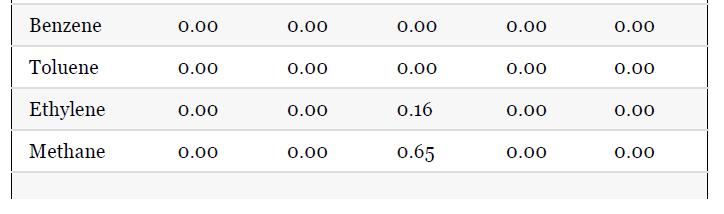

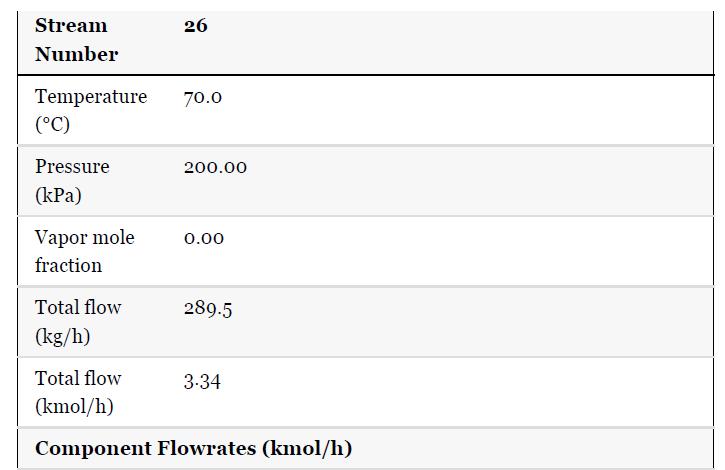

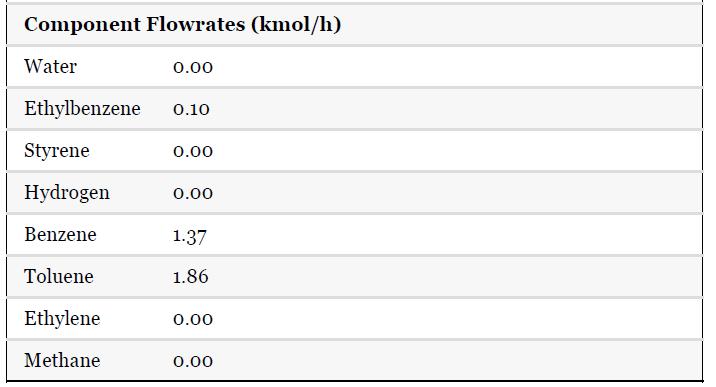

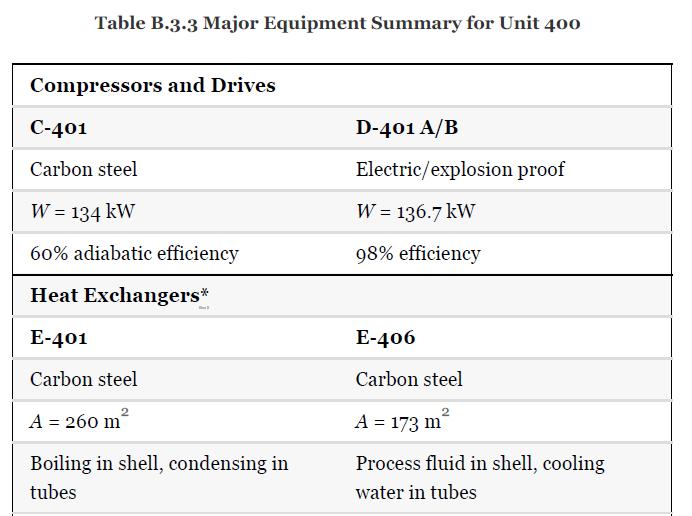

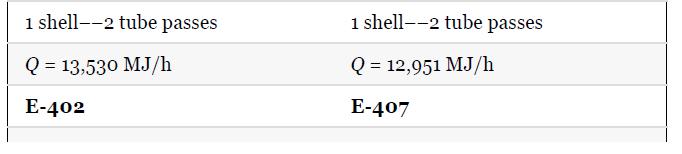

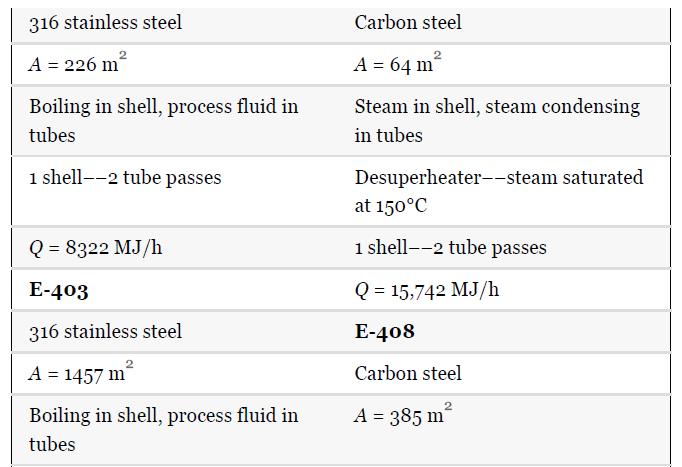

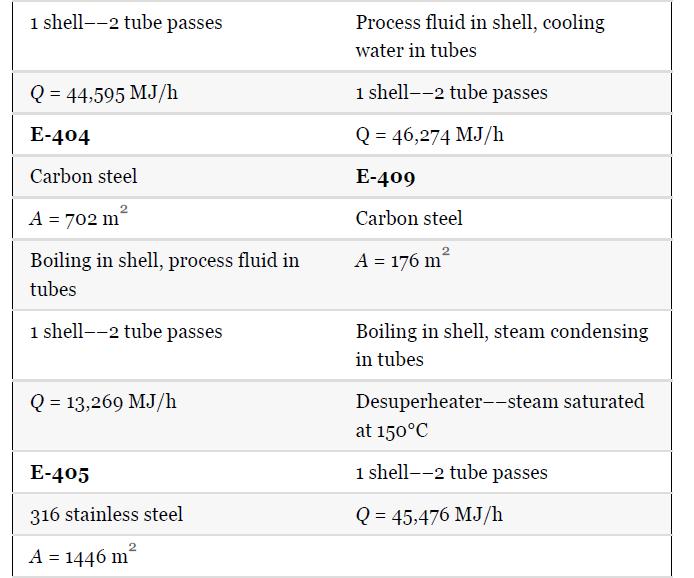

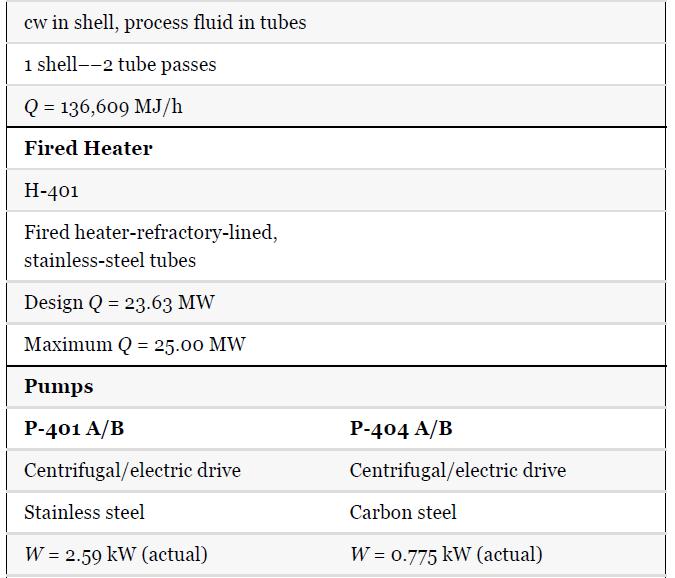

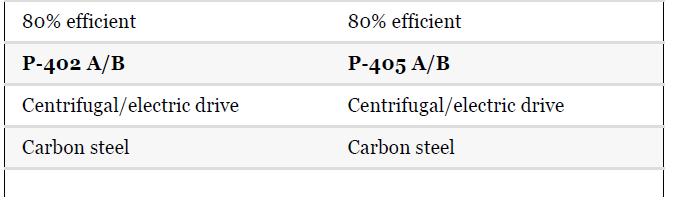

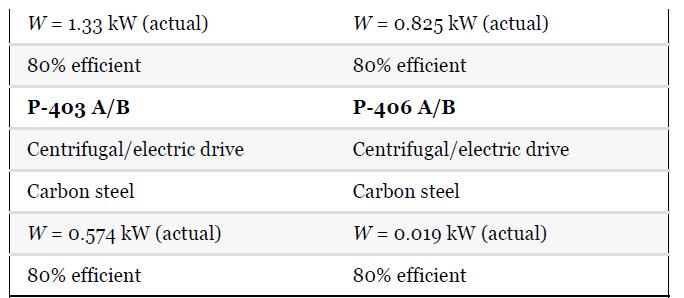

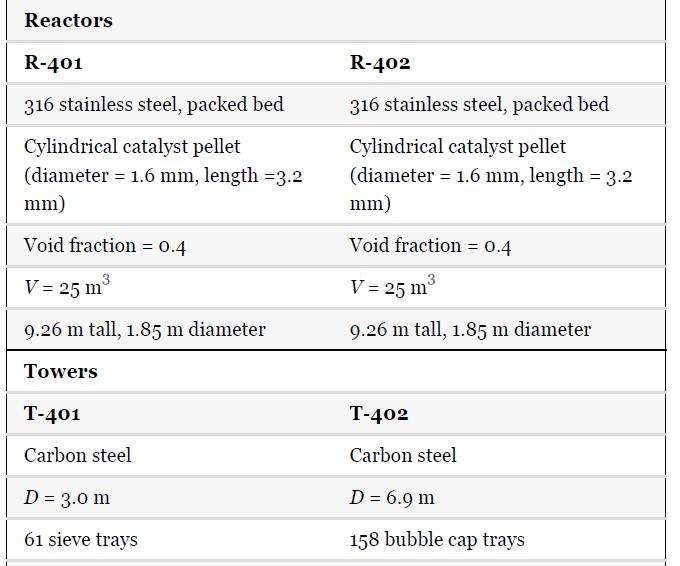

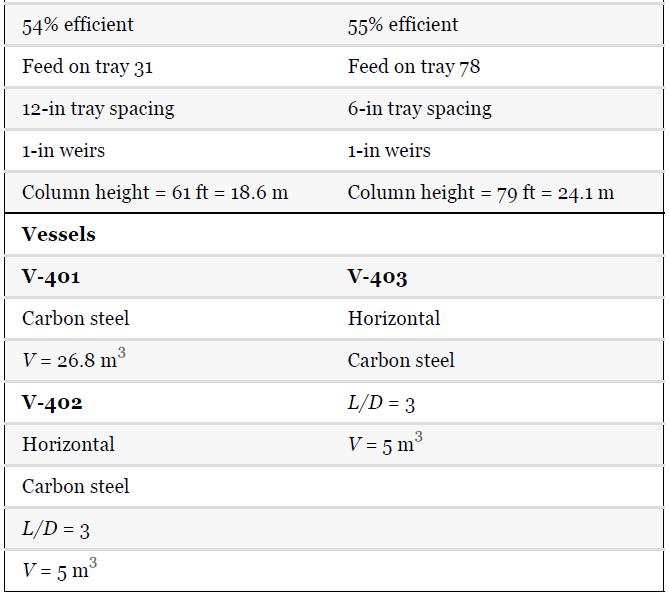

The process flow diagram is shown in Figure B.3.1. Ethylbenzene feed is mixed with recycled ethylbenzene, heated, and then mixed with high-temperature, superheated steam. Steam is an inert in the reaction, which drives the equilibrium shown in Equation (B.3.1) to the right by reducing the concentrations of all components. Because styrene formation is highly endothermic, the superheated steam also provides energy to drive the reaction forward. Decomposition of ethylbenzene to benzene and ethylene, and hydrodealkylation to give methane and toluene, are unwanted side reactions shown in Equations (B.3.2) and (B.3.3). The reactants then enter two adiabatic packed beds with interheating. The products are cooled, producing steam from the high-temperature reactor effluent. The cooled product stream is sent to a three-phase separator, in which light gases (hydrogen, methane, ethylene), organic liquid, and water exit in separate streams. The hydrogen stream is further purified as a source of hydrogen elsewhere in the plant. The benzene/toluene stream is currently returned as a feed stream to the petrochemical facility. The organic stream containing the desired product is distilled once to remove the benzene and toluene and distilled again to separate unreacted ethylbenzene for recycle from the styrene product.

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Answer rating: 100% (2 reviews)

Answered By

David Muchemi

I am a professional academic writer with considerable experience in writing business and economic related papers. I have been writing for my clients who reach out to me personally after being recommended to me by satisfied clients.

I have the English language prowess, no grammatical and spelling errors can be found in my work. I double-check for such mistakes before submitting my papers.

I deliver finished work within the stipulated time and without fail. I am a good researcher on any topic especially those perceived to be tough.

I am ready to work on your papers and ensure you receive the highest quality you are looking for. Please hire me to offer my readily available quality service.

Best regards,

4.60+

27+ Reviews

61+ Question Solved

Related Book For

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780134177403

5th Edition

Authors: Richard Turton, Joseph Shaeiwitz, Debangsu Bhattacharyya, Wallace Whiting

Question Posted:

Students also viewed these Engineering questions

-

Managing Scope Changes Case Study Scope changes on a project can occur regardless of how well the project is planned or executed. Scope changes can be the result of something that was omitted during...

-

Estimate the cost of operating labor (C OL ), the cost of utilities (C UT ), and the cost of manufacturing (COM d ) for the styrene process given in Project B.3 of Appendix B. You must do Problem...

-

Estimate the cost of operating labor (C OL ), the cost of utilities (C UT ), and the cost of manufacturing (COM d ) for the ethylbenzene process given in Project B.2 of Appendix B. You must do...

-

A force F = (3.00 N)i + (7.00 N)j + (7.00 N)k acts on a 2.00 kg mobile object that moves from an initial position of di = (3.00 m)i (2.00 m)i + (5.00 m)k to a final position of df = (5.00 m)i +...

-

Economists continue to be puzzled by the apparent home bias of investors across countries. With mean-variance preferences, investors ought to allocate much more of their wealth to foreign equities...

-

Great Eats needs $2,000,000 to finance a new restaurant in Mytown. The project will be funded from the following sources. Great Eats' effective tax rate is 34 percent with taxes paid annually....

-

Pick an industry and a product or service. Engage in a creative-thinking process, as outlined in Chapter 11, to generate an improved offering. Do the same to create an entirely new offering that uses...

-

Eco Wet, Inc., a manufacturer of gears for lawn sprinklers, is thinking about adding a new fully automated machine. This machine can produce gears that the company now produces on its third shift....

-

Differentiate entity wide controls from transaction controls. Identify at least 3 types of entity wide controls and 3 types of transaction controls. Then, provide an example for each type of control...

-

It has been proposed that the hydrogen/methane stream is handled in the same manner as was the toluene/benzene stream. Recall that the unreacted toluene was separated from the benzene product and...

-

Suggest two reasons why reactors are run at elevated pressures and/or temperatures. Be sure to state clearly which explanation is for elevated pressure and which is for elevated temperature.

-

What exactly is nondestructive testing, and what are some attractive features of the approach?

-

Determine the exact output of the following code segment. Dim a As Integer = 4 Dim b As Integer = 5 Dim temp As Integer = 0 temp = a a = b b = temp Dim result As String = String.Format("The value of...

-

The most recent financial statements for Kerch, Inc., are shown here (assuming no income taxes): Income Statement Balance Sheet Sales $4,800 Assets $14,600 Debt $10,500 Costs 3,470 Equity 4,100 Net...

-

HeadAche Inc. depends on two sources of financing: bond issues and common stock. In the following table, you can see the market value of these two sources as well as required rates of return: Market...

-

A and B have masses of 1 0 4 . 9 and 6 6 4 . 7 kg respectively. These masses are separated by a distance of 4 . 4 meters. How far from mass A would there be no net gravitational force? The distance...

-

Suppose that the base year for CPI is 2014. The cost of the CPI basket in 2014 is $50; the cost of the basket in 2015 was $60, and the cost of the basket in 2016 was $66. What was the CPI in 2015?

-

Go to the Baldrige Award website, www.quality.nist.gov, and research several companies that have won the Malcolm Baldrige Award. Describe any common characteristics that the quality-management...

-

Reread the discussion leading to the result given in (7). Does the matrix sI - A always have an inverse? Discuss.

-

In the production of dimethyl carbonate from methanol, it is necessary to separate methanol from formal (also known as methylalC 3 H 8 O 2 ). However, an azeotrope exists between these two...

-

Illustrate a system (PFD and McCabe-Thiele diagrams) to purify two components (A and B) from a binary, homogeneous, minimum-boiling azeotrope that is pressure sensitive. The feed concentration of A...

-

How many simple distillation columns are required to purify a stream containing five components into five pure products? Sketch all possible sequences.

-

Zeus company factored P6,000,000 of accounts receivable to a finance entity at the beginning of current year. Control was surrendered by Zeus Company. The factor accepted the accounts receivable...

-

What did John B . Watson and Rosalie Rayner demonstrate with their studies of Little Albert?

-

what are the major take aways on both Washington concesus and Beijing concesus?

Study smarter with the SolutionInn App