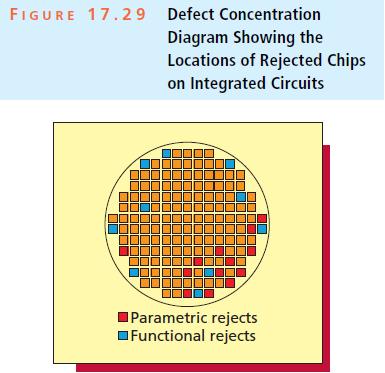

In an issue of Quality Progress, The Juran Institute presents an example that deals with the production

Question:

In an issue of Quality Progress, The Juran Institute presents an example that deals with the production of integrated circuits. The article describes the situation as follows: The manufacture of integrated circuits begins with silicon slices that, after a sequence of complex operations, will contain hundreds or thousands of chips on their surfaces. Each chip must be tested to establish whether it functions properly. During slice testing, some chips are found to be defective and are rejected. To reduce the number of rejects, it is necessary to know not only the percentage but also the locations and the types of defects. There are normally two major types of defects: functional and parametric. A functional reject occurs when a chip does not perform one of its functions. A parametric reject occurs when the circuit functions properly, but a parameter of the chip, such as speed or power consumption, is not correct. Figure 17.29 gives a defect concentration diagram showing the locations of rejected chips within the integrated circuit. Only those chips that had five or more defects during the testing of 1,000 integrated circuits are shaded. Describe where parametric rejects tend to be, and describe where functional rejects tend to be.

Data from Figure 17.29

Step by Step Answer:

Business Statistics In Practice

ISBN: 9780077534844

7th Edition

Authors: Bruce Bowerman, Richard OConnell, Emilly Murphree