Do the following distillation problem after Part A or Part B in Lab 6 is finished. We

Question:

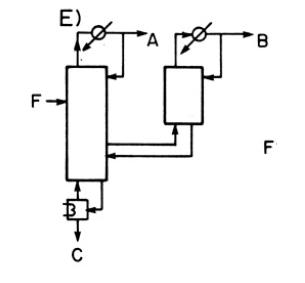

Do the following distillation problem after Part A or Part B in Lab 6 is finished. We are separating \(100.0 \mathrm{kmol} / \mathrm{h}\) of a feed containing propane, \(\mathrm{n}-\) butane, and n-pentane. The feed is a saturated liquid, and feed pressure is \(5.0 \mathrm{bar}\) or less. This feed is \(50.0 \mathrm{~mol} \%\) propane, \(41.0 \mathrm{~mol} \%\) n-butane, and the remainder is n-pentane. In the overall process, we plan to recover \(99.5 \%\) of the propane in the propane product, \(99.2 \%\) of the \(n\)-butane in the n-butane product, and \(99.0 \%\) of the n-pentane in the n-pentane product. Use the flowsheet in Figure 11-6E. For purposes of your initial mass balances, assume (1) there is no n-pentane in the propane product stream, and (2) there is no propane in the n-pentane product stream. Check these guesses after you have run the simulations. Your plant has an existing column with 40 stages (Aspen notation) with a partial condenser and a partial reboiler that is now available. The feed is on stage 10, but can be changed if necessary (which means it costs money to add a new feed location so think twice before proposing a new feed stage). You can put the vapor withdrawal line and the return liquid line from the enricher anywhere in the column. A previous engineer (who left for another job) briefly worked on the problem. He said 40 stages with the feed on stage 10 works, but stage 10 may not be optimum. 5.0 bar pressure works and L/D \(=4.0\) works in the main column, but \(\mathrm{L} / \mathrm{D}\) is probably higher than necessary. He did very little work on the enriching column but thought 15 stages would be more than sufficient. The vapor withdrawal and liquid return should be placed in the range from 18 to 26 stages. Your boss's wisdom: Keep 40 stages and a feed stage of 10 . See how much you can reduce the reflux ratio in the main column, but do this calculation after you have the main and enriching columns connected and running. Start up the simulation of the connected columns using the technique spelled out in Lab 7 for starting the simulation in a two-pressure distillation scheme.

Figure 11-6E

Report the concentrations and flow rates in the three product streams and the total recovery of the three components. Provide enough information that your simulation can be rerun by another engineer. Oh, and good luck.

Report the concentrations and flow rates in the three product streams and the total recovery of the three components. Provide enough information that your simulation can be rerun by another engineer. Oh, and good luck.

Step by Step Answer:

Separation Process Engineering Includes Mass Transfer Analysis

ISBN: 9780137468041

5th Edition

Authors: Phillip Wankat