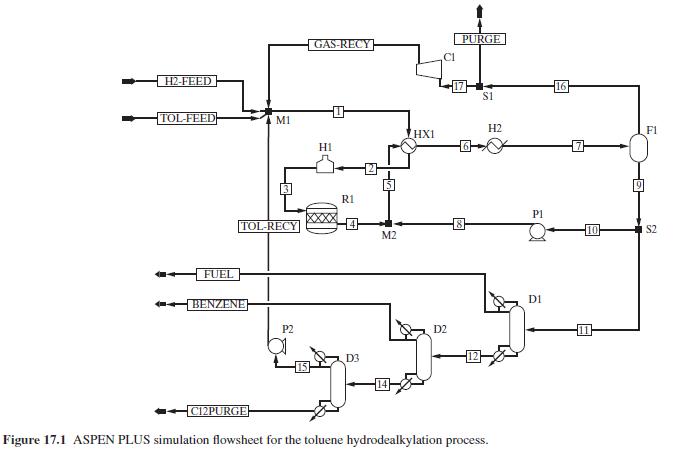

This assignment begins with a completed simulation of the toluene hydrodealkylation process in Figure 17.1 and involves

Question:

This assignment begins with a completed simulation of the toluene hydrodealkylation process in Figure 17.1 and involves the completion of an economic evaluation. Note that the simulation results for this process were developed in solution of Exercise 7.4 and can be reproduced using the HDA.bkp file in the Program and Simulation Files folder on the Wiley Web site associated with this textbook. APEA will be used for equipment and capital cost estimation. The spreadsheet, Profitability Analysis - 4.0.xls, also in the Program and Simulation Files folder, will be used for economic analysis. This spreadsheet will enable you to enter the specifications recommended for capital investment costs and for the cost sheet, and using the approximate profitability measures in Section 17.4 and those involving cash flows in Section 17.6. In most cases, only the nondefault APEA entries are provided in this problem statement. This, together with the description in Section 16.8, should enable you to understand the items on APEA input forms.

Cost Options The project startup date is January 2016 and the project duration is \(16 \mathrm{yr}\) (15 production yrs). For simplicity, the effect of inflation is disregarded in this assignment.

Equipment Unless otherwise stated, the default equipment types and materials of construction are acceptable.

Tanks Toluene storage tank Create a tank to store a two-day supply of toluene.

Benzene storage tank Create a tank to store a two-day supply of the benzene product.

Stream 11 storage tank Create a tank to store a two-day supply of the intermediate stream 11.

Flash vessel F1 Size a vertical flash vessel to have a 10 -minute liquid retention time.

Reactor \(\mathrm{Rl}\)

The elevated temperature \(\left(1,268^{\circ} \mathrm{F}\right)\) and pressure ( \(\left.494 \mathrm{psia}\right)\) present special complications when designing and sizing the hydrodealkylation reactor. This is a large-diameter vessel that is lined with refractory brick to insulate the steel alloy that composes the retaining wall. Initially, use APEA to design a vessel that has a \(10-\mathrm{ft}\) diameter and a \(60-\mathrm{ft}\) tangent-to-tangent length. To estimate the thickness of the refractory brick and the temperature at the brick-steel interface, a heat balance is necessary. In practice, the brick thickness is adjusted to give an interface temperature of \(900^{\circ} \mathrm{F}\). When using APEA, select refractory-lined carbon steel. Using the pull-down menu, select a 9 -inch layer of \(90 \%\) alumina fire brick, symbol 9FB90. Also, consider the possibility of using two or three smaller-diameter vessels in parallel. Finally, compare the costs of horizontal and vertical vessels.

Before mapping the reactor model in the ASPEN PLUS simulation, replace the RSTOIC model (block) with the RPLUG model (block) in ASPEN PLUS. Note, however, that the kinetics of the side reaction cannot be modeled using the RPLUG model (block). Since the conversion of this reaction is small, its kinetics can be neglected in the reactor design. Rather, it is sufficient to account for the reaction using a dummy reactor unit, R1D, modeled with the RSTOIC block, which follows the reactor unit R1, modeled with the RPLUG block. Do not permit APEA to size and cost unit R1D.

Heat Exchangers H2 Use cooling water.

D1, D2, and D3 condensers Use cooling water.

D1, D2, and D3 reboilers Use steam.

Distillation Towers In the ASPEN PLUS simulation, for each distillation column, use the RADFRAC model (block) in place of the DISTL model (block). As a result, the reflux ratios change somewhat to achieve the same product specifications using the same number of trays.

In APEA, set the tray efficiency of the three columns to \(90 \%\).

The reflux accumulators should be horizontal vessels with a liquid holdup time of \(10 \mathrm{~min}\).

Pumps Toluene pump Create a pump to bring the toluene feed from atmospheric pressure to 569 psia.

Benzene pump Increase the pressure of the benzene product stream by 25 psia.

D1 condenser pump Increase the pressure of the D1 reflux by 25 psia.

D1 reboiler pump Increase the pressure of the D1 reboiler pump by 25 psia.

D2 condenser pump Increase the pressure of the \(\mathrm{D} 2\) reflux by 25 psia.

D2 reboiler pump Increase the pressure of the D2 reboiler pump by 25 psia.

D3 condenser pump Increase the pressure of the D3 reflux by 25 psia.

D3 reboiler pump Increase the pressure of the D3 reboiler pump by 25 psia.

Other Equipment Compressor \(\mathrm{Cl}\)

Use a centrifugal compressor.

Use a motor drive and an electrical utility.

Fired heater H1 In the ASPEN PLUS simulation, the HEATER model (block) was used. By default, units modeled with the HEATER block are mapped as heat exchangers by APEA. Instead, this unit must be mapped as a furnace. Furthermore, before estimating the cost of the furnace, the default material, carbon steel, must be replaced by a material that can withstand temperatures up to \(1,200^{\circ} \mathrm{F}\) in the furnace. Note that Inconel is selected from among the materials available in APEA that can withstand this temperature. To replace carbon steel, in row nine of the window that displays the equipment sizes for the furnace, double-click on the equipment item, scroll to locate tube material selection, which opens the pull-down menu on the right. Then, select Inconel. These changes must be saved before leaving this window.

Labor Costs Use a wage rate of \(\$ 40 / \mathrm{hr}\).

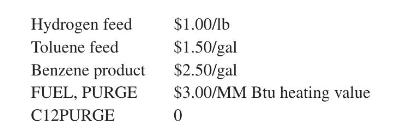

Materials For the feed, product, and byproduct streams H2-FEED. TOL-FEED, BENZENE, PURGE, FUEL, and C12PURGE, the following prices are typical:

The prices are for toluene and benzene at \(1 \mathrm{~atm}\) and \(75^{\circ} \mathrm{F}\). You can use ASPEN PLUS to estimate the densities needed to obtain the prices on a mass basis. (You can also use ASPEN PLUS to estimate the heating value of a stream rather than calculate it independently.) To compute and display the heating values of all streams, access the Property Sets folder, press New, and enter an ID (e.g., PS-5) to obtain the Property Sets tab. From the pull-down menu, select HHV-0 or HHV-15. Then, follow the sequence: Setup \(\rightarrow\) Report Options \(\rightarrow\) Stream \(\rightarrow\) Property Sets. This produces the Property Sets dialog box. From the Available Property Sets, move your ID to the Selected Property Sets and press Close. Then, run ASPEN PLUS and obtain the stream report. Heating values will be displayed for each stream.

Utilities For this process, cooling water, steam, electricity, and fuel are purchased.

Cooling water: \(\$ 0.10 / 1,000\) gal. Use inlet and outlet temperatures of \(90^{\circ} \mathrm{F}\) and \(120^{\circ} \mathrm{F}\).

Steam: Use prices in Table 17.1.

Electricity: \(\$ 0.07 / \mathrm{kW}-\mathrm{hr}\).

Fuel (to heater H1): Assume the heater is gas fired at a cost of \$2.60/MM Btu.

Operating Costs The plant is anticipated to operate 330 days a year.

Average hourly wage rate is \(\$ 40 / \mathrm{hr}\) with two operators per shift.

Profitablity Analysis Project a 15 -yr life for the plant.

Assume a \(15 \%\) interest rate to calculate the net present value.

For cash flow analysis, use the 5-yr MACRS depreciation schedule. Estimate the effective tax rate to be \(40 \%\) with no investment tax credit.

Assume a production schedule such that the plant operates at \(50 \%\) of full scale ( \(90 \%\) of capacity) in the first year, \(75 \%\) of full scale in the second year, and \(100 \%\) of full scale thereafter.

Provide for the cost of startup at \(20 \%\) of the total materials and labor cost of the process units.

Provide for working capital to cover 2 days of raw material inventory, 2 days of in-process chemicals, 2 days of finished-product inventory, and 30 days of accounts receivable.

Figure 17.1:-

Data From Exercise 7.4:-

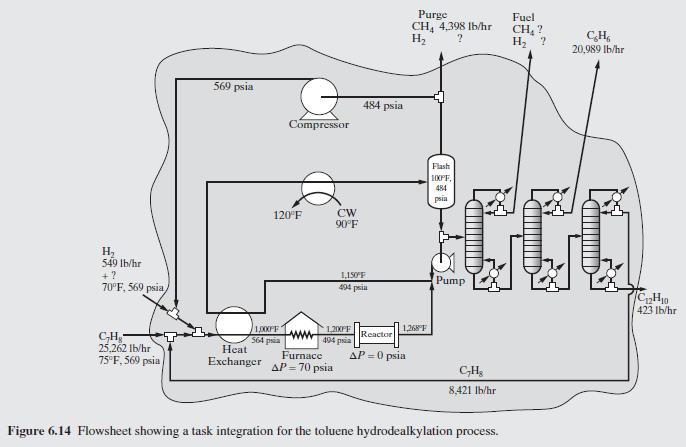

Complete a simulation of the entire process for the hydrodealkylation of toluene in Figure 6.14. Initially, let the purge/recycle ratio be 0.25; then, vary this ratio and determine its effect on the performance of the process. Use a design specification to determine the unknown amount of hydrogen to be added to the feed stream (equal to that lost in the purge). If using ASPEN PLUS, the distillation columns can be simulated using the RADFRAC module with the number of stages and reflux ratio previously computed by the DSTWU module.

Figure 6.14:-

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng